Seeing what you master craftsmen are up to, I'm ashamed to say that all I did was building a roof rack for my Outback. It allows me to load my OT W/C with yoke pads installed. (The factory rack is very low.) Coyote-ugly 2x4 construction.

-

Happy Sacagawea Day! 🧭🧑🏽🍼🪶🏞

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's happening in your shop this winter?

- Thread starter Alan Gage

- Start date

Nothing like a deadline to get a project finished and I thought I'd share some pics. This is the Mad River Malicite that I took the gunnels off of last fall. I finished it off the same way as its sister seeing as they live side by side. I've tried many different ways of fastening the seats and this is the easiest time I've had of it. The varnish was still to green to use the strap or other clamp arraignment I've used in the past and this is the way I'll be doing it from now on. Just a piece of styrofoam against the hull and then a scissor jack to push up. It held the seat perfectly. The long drill has always been the best way to line everything up.

Jim

Jim

Looks great !

I've been using a long 1/4" bit to drill for seat brackets for a long time.

It's great to insure alignment, of the hanger bolt, bracket and seat.

I use those furniture clamps instead of the jack though.

Jim

I've been using a long 1/4" bit to drill for seat brackets for a long time.

It's great to insure alignment, of the hanger bolt, bracket and seat.

I use those furniture clamps instead of the jack though.

Jim

Yea Jim I've used clamps in the past too, but he last coat of varnish was not even 24 hours old so no way was I going the subject it to clamps. And it freed up the whole gunnel to for easy sighting of the drill.

Jim

Jim

True story, I had agreed to deliver that canoe to the house today and it happens to be raining. No problem, just get a little wet that's all. As it turns out the property manager (yes you read that right) called and said he would rather have the canoe delivered next week as he didn't want it to get wet! I didn't have the heart to tell him that it was stored outside at my shop. The boats live on low saw horses by the lake shore all summer, but he'd didn't want to get it wet, oh brother.

Jim

Jim

Repair work done. The really deep scratches, the ones into the cloth, mostly did not come out and are now buried under the new layer of 6 oz glass for posterity. It just helps give it the lived in look really. As usual, my choice of varnish is Epifanes. I really don't like the poly-urethane's for outside a hull, they do ok for inside but need to be re-coated more often as they don't wear well.

You are right Jim, gloss has much more UV protection. In fact most of the satin varnish is not intended for exterior use.

Jim

Jim

I started on the old Allagash 17'2", new spliced ash rails so far. I also have almost finished a Mad River Winoski on the rack, some more Interlux 90 varnish on the wood and buff up the hull.

Sold that Bell Northstar and the factory fiberglassed Old Town Trapper. The trapper is going to be used for display at a business that does ADK type home restorations.

Allagash with punky wood rails,

New rails on Allagash, Mad River Winooski on the right,

Winooski,

Sold that Bell Northstar and the factory fiberglassed Old Town Trapper. The trapper is going to be used for display at a business that does ADK type home restorations.

Allagash with punky wood rails,

New rails on Allagash, Mad River Winooski on the right,

Winooski,

Last edited:

No Title

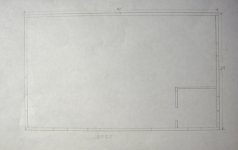

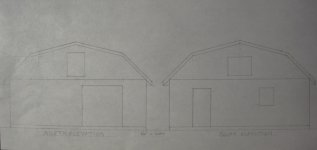

We need a new shop. The one we do the actual building in is fine but is a 1950's single car garage so it is small and low ceiling and not good for the wood working part of life. The outbuilding which we call the boat house gets used as much as possible for the cutting and such but is unheated and quite literally falling down, it is 80 plus years old and lower than the grounds around it, thus the studs have rotted off at the bottoms. It is only a matter of time before it falls down on it's own. Other than a bunch of clutter and is where Christy does her small engine repair, it houses 8 canoes presently, 5 of which are in the queue to get worked on. So, we either spend a couple of grand to fix the one corner that is collapsing or, potentially put up a new building, which in the long run is the better choice, albeit likely in the 40k range.

I looked into different free software for building, including Chief Architect, which is amazing in what it will do, but mostly they are all overkill for a simple shell structure like we would be getting. Having a need for at least simple drawings for potential contractors to base quotes upon, I spent an hour this afternoon with some paper and my scale ruler and came up with basic drawings for the structure we would like to have. 40 foot long gives plenty of room to run the table saw for gunwales and the space along the East wall to have all the boat racks on one wall. A drive in door on the front and maybe, loft space for storage.

We need a new shop. The one we do the actual building in is fine but is a 1950's single car garage so it is small and low ceiling and not good for the wood working part of life. The outbuilding which we call the boat house gets used as much as possible for the cutting and such but is unheated and quite literally falling down, it is 80 plus years old and lower than the grounds around it, thus the studs have rotted off at the bottoms. It is only a matter of time before it falls down on it's own. Other than a bunch of clutter and is where Christy does her small engine repair, it houses 8 canoes presently, 5 of which are in the queue to get worked on. So, we either spend a couple of grand to fix the one corner that is collapsing or, potentially put up a new building, which in the long run is the better choice, albeit likely in the 40k range.

I looked into different free software for building, including Chief Architect, which is amazing in what it will do, but mostly they are all overkill for a simple shell structure like we would be getting. Having a need for at least simple drawings for potential contractors to base quotes upon, I spent an hour this afternoon with some paper and my scale ruler and came up with basic drawings for the structure we would like to have. 40 foot long gives plenty of room to run the table saw for gunwales and the space along the East wall to have all the boat racks on one wall. A drive in door on the front and maybe, loft space for storage.

Attachments

G

Guest

Guest

Karin,

I like the small separate room with two windows; clean space, mini office, fresh air flow when the bigger shop area is fumie.

That little office/clean air space is my favorite part of my shop.

I like the small separate room with two windows; clean space, mini office, fresh air flow when the bigger shop area is fumie.

That little office/clean air space is my favorite part of my shop.

Always exciting to be planning a big project!

In my opinion 24' isn't wide enough. If you have the space to go wider do it. By the time you hang all your boats along one wall and your lumber on the other you're going to be back in your single stall garage, albeit a really long one. Ok, maybe that's an exaggeration, but I've never heard anyone say they wished they would have built a smaller shop. But nearly everyone wishes they'd built a bigger one. They always fill up faster than you think.

I think the design looks really nice but personally I don't like windows in work shops. They limit where racks, shelves, and equipment can go, are going to be covered in dust most of the time, are less energy efficient than a wall, and are one more thing to break when you have a temper tantrum and start throwing hammers. Every winter I make more shelves, racks, and tool boards to go on the walls. If I'd put in windows, which I seriously considered, they'd all be covered up by now. Both my walk-in doors have glass and I have 3 windows in my large overhead door too. That's enough for me to see what's going on outside and who pulled in the driveway.

When I built my shop I did so with the intention of putting a full length 10' wide lean-to roof off the east side. Adding the ledger boards at the time of construction made it a lot easier. It's protected from the hot west sun and prevailing west wind and makes a relaxing place to sit as well as a good place to store yard tools, ladders, lawn mower, lumber, and boats (temporarily). All the stuff you thought there would be room for in the shop but that there really isn't. It can also make a nice outside work space that's protected from the weather.

Happy planning. I'm sure there will be about 80 revisions.

Alan

In my opinion 24' isn't wide enough. If you have the space to go wider do it. By the time you hang all your boats along one wall and your lumber on the other you're going to be back in your single stall garage, albeit a really long one. Ok, maybe that's an exaggeration, but I've never heard anyone say they wished they would have built a smaller shop. But nearly everyone wishes they'd built a bigger one. They always fill up faster than you think.

I think the design looks really nice but personally I don't like windows in work shops. They limit where racks, shelves, and equipment can go, are going to be covered in dust most of the time, are less energy efficient than a wall, and are one more thing to break when you have a temper tantrum and start throwing hammers. Every winter I make more shelves, racks, and tool boards to go on the walls. If I'd put in windows, which I seriously considered, they'd all be covered up by now. Both my walk-in doors have glass and I have 3 windows in my large overhead door too. That's enough for me to see what's going on outside and who pulled in the driveway.

When I built my shop I did so with the intention of putting a full length 10' wide lean-to roof off the east side. Adding the ledger boards at the time of construction made it a lot easier. It's protected from the hot west sun and prevailing west wind and makes a relaxing place to sit as well as a good place to store yard tools, ladders, lawn mower, lumber, and boats (temporarily). All the stuff you thought there would be room for in the shop but that there really isn't. It can also make a nice outside work space that's protected from the weather.

Happy planning. I'm sure there will be about 80 revisions.

Alan

Always make it bigger !!!

Mine is a 26' X30'. I store one truck in there, and there is no room to store anything, and still work on two canoes.

Wider as Alan suggests ! OH And insulate, right after you're done wiring !

Sorry ! We've gone from handing advise out about canoes, to how to build a shop !

That's just what we do ! HA !

Jim

Mine is a 26' X30'. I store one truck in there, and there is no room to store anything, and still work on two canoes.

Wider as Alan suggests ! OH And insulate, right after you're done wiring !

Sorry ! We've gone from handing advise out about canoes, to how to build a shop !

That's just what we do ! HA !

Jim

- Joined

- Mar 20, 2013

- Messages

- 3,356

- Reaction score

- 972

Bigger, bigger, bigger... I have no room for bigger ... So mine is 16x20 and that is as big as I can go

... So mine is 16x20 and that is as big as I can go ... I Know it is too small... but it is better than my 12x12 basement shop I have right now

... I Know it is too small... but it is better than my 12x12 basement shop I have right now ....

....

The idea is to replace the existing building which is 20x30. The lot is only 50 feet wide so there are restrictions on distance from lot lines. Daylight is soothing and windows cut down on the thought of putting up more shelves. If I do it right there will be loft space for some storage. It's own service, fully wired, insulated, in floor heating?, maybe a screened porch on the back. All possible if you have enough money. I never throw tools, I would just have to replace them.

As much as I would like the space to wall it off and have separate sides, one for actual wood working, the other for finishing, thinking spray booth, that just isn't in the cards. The single care garage space will be the finishing space.

There are many options for the actual building, steel with straight sides like Alan's, steel Quonset hut style (crappy wall space issues due to the curve) but the standard wood walls and stick framed roof is what I know and prefer. Barn style to fit the agricultural town.

I think this build thread is what Canot aspires to... http://forums.wcha.org/showthread.php?1876-What-I-ve-been-up-to&highlight=Timber+Frame

As much as I would like the space to wall it off and have separate sides, one for actual wood working, the other for finishing, thinking spray booth, that just isn't in the cards. The single care garage space will be the finishing space.

There are many options for the actual building, steel with straight sides like Alan's, steel Quonset hut style (crappy wall space issues due to the curve) but the standard wood walls and stick framed roof is what I know and prefer. Barn style to fit the agricultural town.

I think this build thread is what Canot aspires to... http://forums.wcha.org/showthread.php?1876-What-I-ve-been-up-to&highlight=Timber+Frame

A good friend in Minnesota, had a small canoe building shop, that burnt down, due to a wood burner. Built a new extra deep two car garage, with a loft to serve as his building area. The loft turned out to be more expensive, than if he had built a bigger garage. The pull down ladder, the trussed floor, and the fact everything thing had to be elevated, added to his bigger expense.

The last time I visited, the loft was used more for storage.

One thing I noticed was the heavy duty, pull down stairs, took up a lot of space, booth upstairs, and at ground level. To me, hauling big tools up stairs just wouldn't work, and it didn't for him.

It is usually cheaper to build a longer two garage, than it is to make it wider, because of the truss rafters.

Just some thoughts !

But the best of luck ! I am so happy I finally have a dedicated canoe shop ! I know you will enjoy yours when done, what ever size you make !.

OH ! One last thing beware of accumulating JUNK. I have that problem !

Jim

The last time I visited, the loft was used more for storage.

One thing I noticed was the heavy duty, pull down stairs, took up a lot of space, booth upstairs, and at ground level. To me, hauling big tools up stairs just wouldn't work, and it didn't for him.

It is usually cheaper to build a longer two garage, than it is to make it wider, because of the truss rafters.

Just some thoughts !

But the best of luck ! I am so happy I finally have a dedicated canoe shop ! I know you will enjoy yours when done, what ever size you make !.

OH ! One last thing beware of accumulating JUNK. I have that problem !

Jim

That some good advise Jim. The last comment about junk is a hard one to battle. I know I have too much, I'm starting to think about thinning everything out.

Jim

Jim

The loft turned out to be more expensive, than if he had built a bigger garage.........One thing I noticed was the heavy duty, pull down stairs, took up a lot of space, booth upstairs, and at ground level.

The house I built is relatively small at 1000 sq. ft. and I spent a lot of time trying to find a good place for the stairs so that I could have a basement workshop and extra living quarters if needed in the future. In the end they ate up too much real estate and I built on a slab instead. Thought about a loft in my shop too but didn't want stairs or dealing with outside access in winter or bad weather. Like you said it was cheaper and simpler to add square footage to the floor and fill the attic with insulation.

Sometimes for some people smaller is better though. Cheaper to build and cheaper to heat/cool. Forces you to be efficient with your layout and storage. Just about everyone told me I should build my house bigger but I was set on keeping it around 1000 sq. ft and single level. I'm happy with it and I can heat it 100% with my little 1.1 cubic foot wood stove.

Alan

The loft space would only be for storage, boats maybe and wood. It doesn't need to be heated at all and could be accessed from inside and out, depending on what I choose. I personally don't like trusses since you need someone to build them for you which adds cost and you lose that space for whatever uses may arise.

Bigger isn't an option either, I had a hard enough time convincing Christy to take it to 24 x 40. The 24 would allow putting in footings Before tearing down the old building. At this point we don't even know what the Township would require as well, so it could all be moot.

Also the big door on the front would not be for keeping vehicles in the building, but better access than a man door, although it would allow indoor vehicle work should it be necessary. We do as much vehicle work ourselves as possible considering the local shops are $85 an hour labour and dealerships are around $130 an hour.

Alan, that is a big house for one person, lol.

Bigger isn't an option either, I had a hard enough time convincing Christy to take it to 24 x 40. The 24 would allow putting in footings Before tearing down the old building. At this point we don't even know what the Township would require as well, so it could all be moot.

Also the big door on the front would not be for keeping vehicles in the building, but better access than a man door, although it would allow indoor vehicle work should it be necessary. We do as much vehicle work ourselves as possible considering the local shops are $85 an hour labour and dealerships are around $130 an hour.

Alan, that is a big house for one person, lol.

G

Guest

Guest

When I built my shop I did so with the intention of putting a full length 10' wide lean-to roof off the east side. Adding the ledger boards at the time of construction made it a lot easier

maybe a screened porch on the back.

If I made one renovation to my existing shop it would be to add a small open-sided carport off the garage door end, preferably with a contiguous slab floor. Some place shop-convenient where I could take boats when sanding to keep the dust out of the shop, wash boats when it is blazingly hot and sunny in the yard and dry tents and gear post trip when it is rainy. Taking wet sand or dirt spattered tents to hang dry in the basement means I have to vacuum up the detritus.

OK, maybe one wall on that carport where I could hang yard tools. And open rafters for storage. Maybe someday; it would have been much easier to build that carport at the same time, or at least like Alan have added the ledger boards during construction.

Daylight is soothing

I like at least a few windows, in part for breeze and ventilation (and running an exhaust window fan during stinky tasks). But working with natural light is beneficial at times, so my main work surfaces, both seated and standing height benches, have a window. I am fortunate that the side of the shop with the two bench windows also provides a long view or who or what is coming down the driveway.

in floor heating?

I think heating depends on the temperature extremes where you live. Hereabout the winter lows only occasionally see the single digits and summertime highs frequently top 100F. The concrete slab floor in the shop functions nicely as passive heating and cooling.

It is in the upper 80’s and humid outside right now, but my shop is at a comfortable 68. The slab floor is cool, almost cold still. By summer’s end the floor will have slowly warmed up and provide some passive heating in the winter months.

The shop was built over-insulated for this clime and even without running a heat source the shop rarely gets below 45F in the winter, so getting it up to a comfortable working temp is easy.

One downside to a slab floor is the humidity. We don’t have air conditioning in our home, but I use a window unit in the shop at times to drop the hygrometer.

Yeah, I have a hygrometer in the shop, and a barometer. And a min/max thermometer.

http://www.amazon.com/Min-Max-Thermometer-Button-Scientific/dp/B005QF35WY

Shop conditions are kinda fun to monitor.

Similar threads

- Replies

- 161

- Views

- 11K

- Replies

- 13

- Views

- 2K

- Replies

- 14

- Views

- 907

- Replies

- 11

- Views

- 1K