- Joined

- Jan 15, 2016

- Messages

- 177

- Reaction score

- 0

Robin, nice work.

Alan, the CF hockey shafts I have are hollow. They're made by wrapping stacked layers of thin pre-preg carbon fibre material around a mould or mandrel, and then it's oven-cured. First the mould is wrapped with thin clear poly release film (this stays inside the shaft), and then the carbon fibre (could also be fibreglass, Kevlar, or some combination) is wrapped over that. Processes are proprietary of course. The orientation and concentration of fibres varies depending on the specific requirements for a particular stick-- it would include specs like stiffness, weight, and location of max flex on the shaft (the sweet spot).

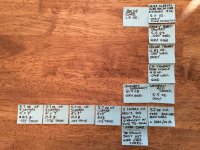

I've taken some measurements of wall thickness, and it varies (I found some as thin as .054" and as thick as .075", with .063" as a nominal thickness); the range is probably greater, but this is taken from the armful of sticks I have in the shop. Apparently there are up to 15 layers of carbon fibre in the wrap. I don't know what thickness of cloth they use, but it must be very thin.

A typical sample of 3Kx3K 2x2 Twill @ 5.7 oz/sqyd bags out to .009". It would take just 7 layers of this basic CF cloth to bag out at .063". It would seem they are using material half that weight and thickness-- perhaps 3 oz that bags out at .0045". But I don't know.

Alan, the CF hockey shafts I have are hollow. They're made by wrapping stacked layers of thin pre-preg carbon fibre material around a mould or mandrel, and then it's oven-cured. First the mould is wrapped with thin clear poly release film (this stays inside the shaft), and then the carbon fibre (could also be fibreglass, Kevlar, or some combination) is wrapped over that. Processes are proprietary of course. The orientation and concentration of fibres varies depending on the specific requirements for a particular stick-- it would include specs like stiffness, weight, and location of max flex on the shaft (the sweet spot).

I've taken some measurements of wall thickness, and it varies (I found some as thin as .054" and as thick as .075", with .063" as a nominal thickness); the range is probably greater, but this is taken from the armful of sticks I have in the shop. Apparently there are up to 15 layers of carbon fibre in the wrap. I don't know what thickness of cloth they use, but it must be very thin.

A typical sample of 3Kx3K 2x2 Twill @ 5.7 oz/sqyd bags out to .009". It would take just 7 layers of this basic CF cloth to bag out at .063". It would seem they are using material half that weight and thickness-- perhaps 3 oz that bags out at .0045". But I don't know.

Last edited: