There are several operations going on in parallel at this point in the build, but I will break them out into discreet steps to make it easier to follow.

This post will cover off laying out where the seat, thwarts and hand holds will be installed and the basic install itself .... plus a bit about the construction of them.

First step is to figure out where the "center of balance" is on the boat. Since this isn't a symmetrical hull, that won't be in the middle, in fact, for most boats it likely won't be exactly in the center lengthwise due to inconsistencies in the build IMO.

I have a "balance stick" cut so it just fits under the gunnels side-to-side at "about" the middle with a bit of clearance

I lift the boat by the stick and see if it is balanced ... moving it back or forward until it does balance. At this point I make a mark on the gunnel of one side, where the stick is placed.

Next, I want to make sure I get a second mark square to the first mark and I do this with a simple pendulum. Hook a length of non-stretchy cord around the tip pf the deck end and pull it taunt to the first mark, then swing it over to the opposite gunnel and make a mark.

Line the balance stick up with each mark and see if the boat balances ... move it fore and aft as required, keeping about equidistant from the marks you have made. Once it is balanced, make a new mark on one side and then use the string to make the second mark. Check the new marks and hopefully you are done at that point, you have determined and marked the center of balance for the boat.

You will be adding a seat and thwarts, which will impact this center, if want to do this determination with those items placed in "about" the right locations, it will make the point better. In my case, I know where the seat is going (aft of center) and that I will be adding footbraces (fore of center) and these will just about perfectly cancel out ... the thwarts and handles are pretty light and will have minimal impact on the overall balance point.

The layout points for the seat/thwarts/yoke are all relative to the balance point you just marked, the center of the yoke obviously goes through the balance point, the seat front edge is located 4"-6" (6" for me) aft of the center and the rear thwart is 7" aft of the trailing seat edge. The front thwart is located 30" forward of the center balance.

These locations can be marked on the gunnels or add tape and mark the tape ...

Obviously if you have plans that give you specific locations, it is best to use those, but for a 15'-16' foot solo, there will be little difference in the location points IMO.

There is a rationale for these locations (not a rule) ... for the seat, most people will hunch forward when seated, this moves there center forward about 6", so moving the seat back a bit locates the heaviest load over the balance point. Th rear thwart gets leaned back on from time to time (at least I do) and keeping it back about 7" is about right, far enough back that it doesn't hit you when you are paddling, far enough forward that you get a little support if you lean back. The forward thwart is placed to be in the area where your feet/ankles are ... so that it doesn't interfere with entry/exit or moving your legs around.

Here you can see the start of the layout for the rear thwart, the tape is marking the seat location, the stick is near the balance point, you can just see the tape underneath the rough thwart, that marks its location

In parallel I have been doing the seat, yoke, handle and thwart lamination ... so some of the pics have other stuff ... when doing epoxy work I like to make the batch go as far as I can each time.

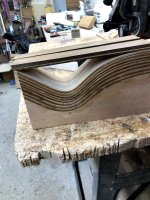

Thwart layup is just strips glued up with epoxy, in this pic you can see a piece of pine added in, this is to keep the lamination "straight", I have found at times a lamination can bend a bit if it doesn't have straight edge to hold it .. sometimes. This is actually an "after" shot, the epoxy has set and I removed the end clamps, it's just to show the layup.

A note on the "lamination" I am using, it is cherry and white cedar ... the idea is to use the white cedar as a filler between cherry pieces to give a bit of bulk and keep weight as low as reasonable.

I did a few layups at the same time, this is some pieces for the yoke (left - will cover later), then seat struts (again, later) and the aft and fore thwart. I did an extra piece of the yoke lamination to use as handles.

This is where I ran into a bit of a snag with the thwarts ... I sized them to be as light as possible and still be strong enough (my judgement) and they did meet that criteria, but when I placed them on the boat ... they just weren't proportioned right, they looked "skimpy", too skimpy

Sooo, back I went to new strips

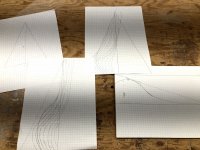

New glue up being marked out

And a look at new versus old

Now that things are laid out and we know where everything is going, attachment will be done via 10-24 x 1.5" carriage bolts ... so that brings up the issue of limited gunnel real estate at the attachment points, which I did expect, although it could be done as is, I prefer to place "add ons" at the mounting points to give me more real estate and a stronger attachment point.

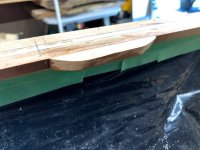

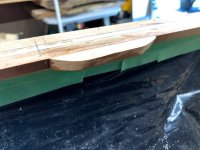

I took small pieces of the spare outer gunnel I made, and created "add ons" for the thwarts and handles, you can see those on the previous picture

They are marked with a centerline, placed on the mounting area, the bottom aligned to the flat, leaving about 1/4" overhang at the top. Once lined up, a pencil line is drawn so that it can be aligned once epoxy is added.

To mount, just saturate the gunnel area and the add on piece, then add thickened epoxy, I like to put that on the gunnel side ... align the add on and clamp, I just use 1 or 2 spring clamps

The above pic is after I have cleaned up the squeeze out, you want to get any excess off the joint while it is still liquid-ish ... I use a finger (gloved) followed by a paper towel.

Next day, I use a plane to take them just down to the gunnel

and a quick sand to make them match ... sanding was for demo, I don't usually do that until later when I do the gunnel prep

The handles are a cherry-white cedar-cherry laminate to match the rest fo the trim, here they are ready to install

and how the handle fits the hull ... I moved them back about 5" from the decks.

So ... this covers laying out the trim pieces, making the trim pieces, adding the "add ons" for mounting and a comparison of thwarts as imagined and then as built when imagination doesn't work out too well in reality. I am not ready to start drilling holes and mounting stuff yet, for one the carriage bolts are on order, not in my hand and also because i don't like to do anything to the gunnels (like drilling, round over etc) until I have all my pieces fitted and accounted for ... since i have the seat made but it is being fitted and the yoke is designed, but I am waiting on a cutter, i will leave gunnel finishing and trim install until those jobs are done.

Brian