Thanks guys.

Jim: Regarding weight management, I'm certainly a newbie to canoe building, but not general woodworking. With properties that matter, depending on application, I measure and/or test a variety of samples from my pile. I use density charts as a starting point:

cedarstripkayak.wordpress.com

cedarstripkayak.wordpress.com

When I started thinking about woods for trim on my stripper, I tested samples from stock of Ash, Walnut, Cherry, Butternut, Teak. According to chart, Ash is 40-53 lbs/cu. ft. Mine all tested at or slightly above the high end. My walnut & cherry was mostly at the low end of 40-45. Of course for most woodworking lighter = lower density, something I don't want for many applications, so I have a pretty good pile of wood I've sort of put on hold that will be excellent for canoe trim.

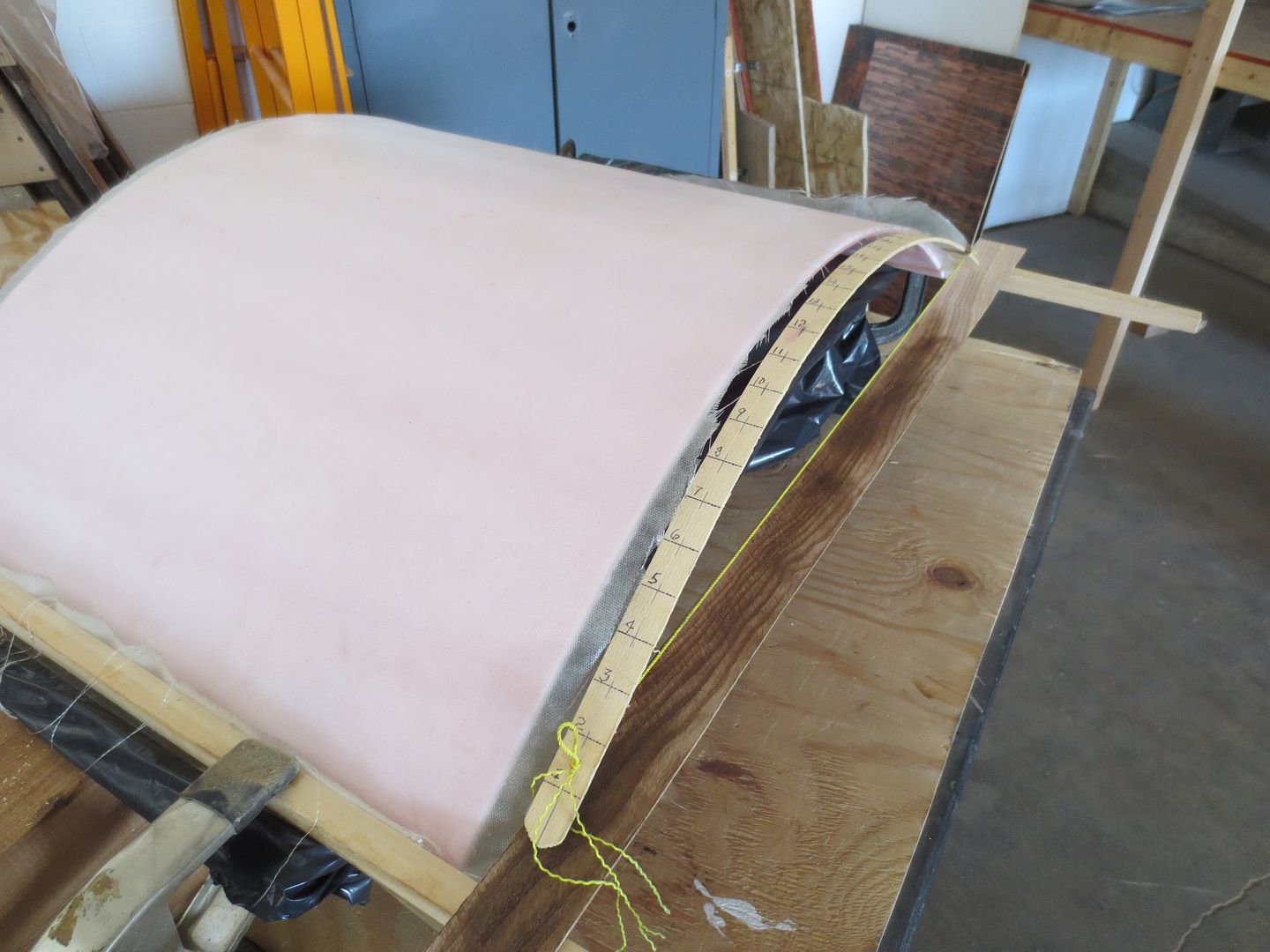

I'm really anxious to get my stripper weighed. Even though I didn't set out to make it as light as possible, I think I'm going to be pleasantly surprised. Unfortunately, I didn't weigh my trim components before I put them on. I'm working on trim now for my next build, so I'll weigh stuff and keep track better on this one as I go.

Jim: Regarding weight management, I'm certainly a newbie to canoe building, but not general woodworking. With properties that matter, depending on application, I measure and/or test a variety of samples from my pile. I use density charts as a starting point:

Wood Density Chart

Wood Density and Specific Gravity The Following chart will tell you how much weight you can expect from your wood selection. A simple comparison of the lb/ft3 of cedar and any other species will t…

When I started thinking about woods for trim on my stripper, I tested samples from stock of Ash, Walnut, Cherry, Butternut, Teak. According to chart, Ash is 40-53 lbs/cu. ft. Mine all tested at or slightly above the high end. My walnut & cherry was mostly at the low end of 40-45. Of course for most woodworking lighter = lower density, something I don't want for many applications, so I have a pretty good pile of wood I've sort of put on hold that will be excellent for canoe trim.

I'm really anxious to get my stripper weighed. Even though I didn't set out to make it as light as possible, I think I'm going to be pleasantly surprised. Unfortunately, I didn't weigh my trim components before I put them on. I'm working on trim now for my next build, so I'll weigh stuff and keep track better on this one as I go.