- Joined

- Aug 11, 2023

- Messages

- 1

- Reaction score

- 1

What is missed from reading this and a variety of other posts is how the bow and stern get closed up after taking the composite off the mold. I have an old Ellery Canoe that needs new life but in the end I might use it as a plug for a composite. If anyone can point me in the right direction re how to work on the bow and stern, it would be appreciated.

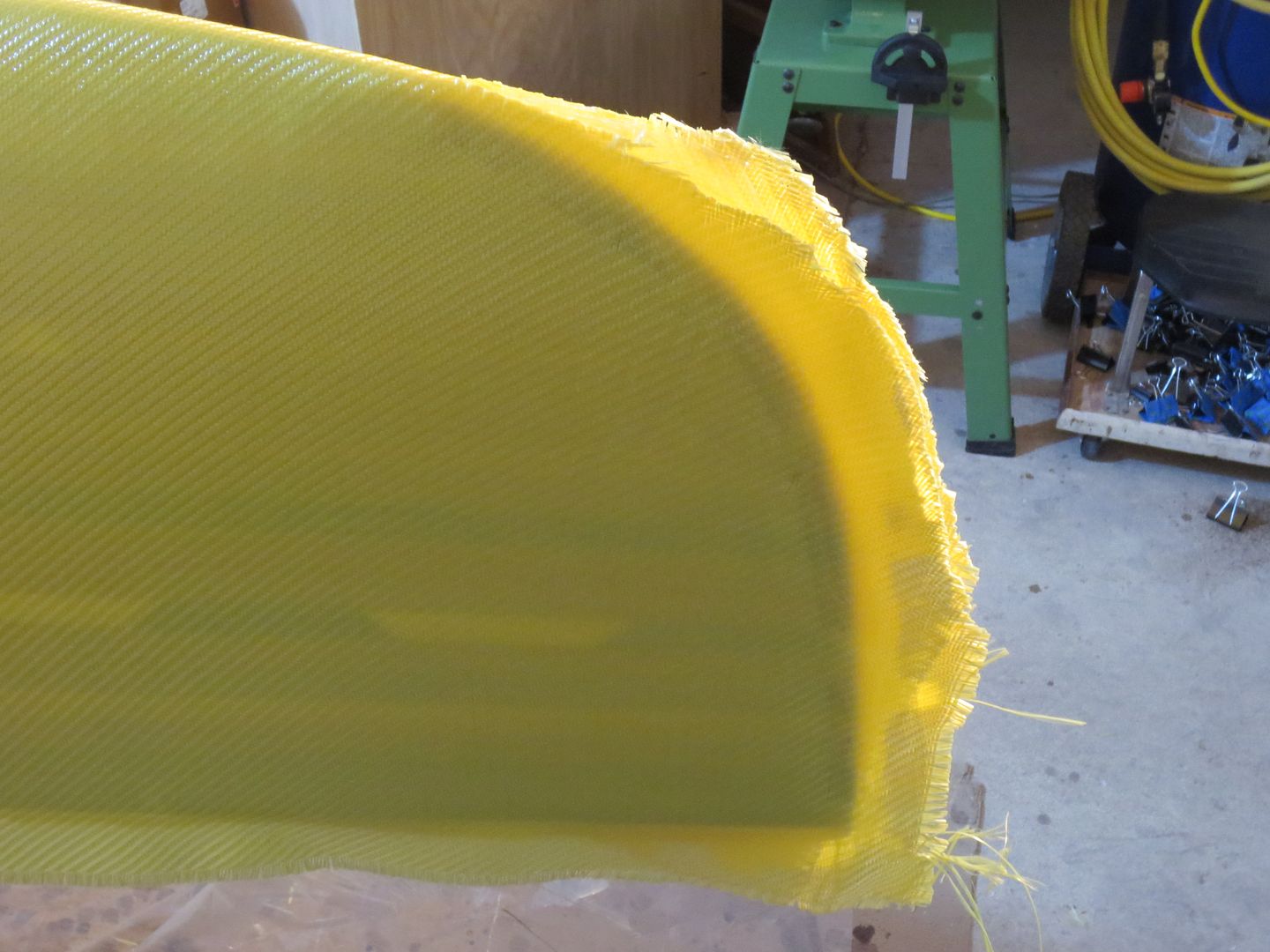

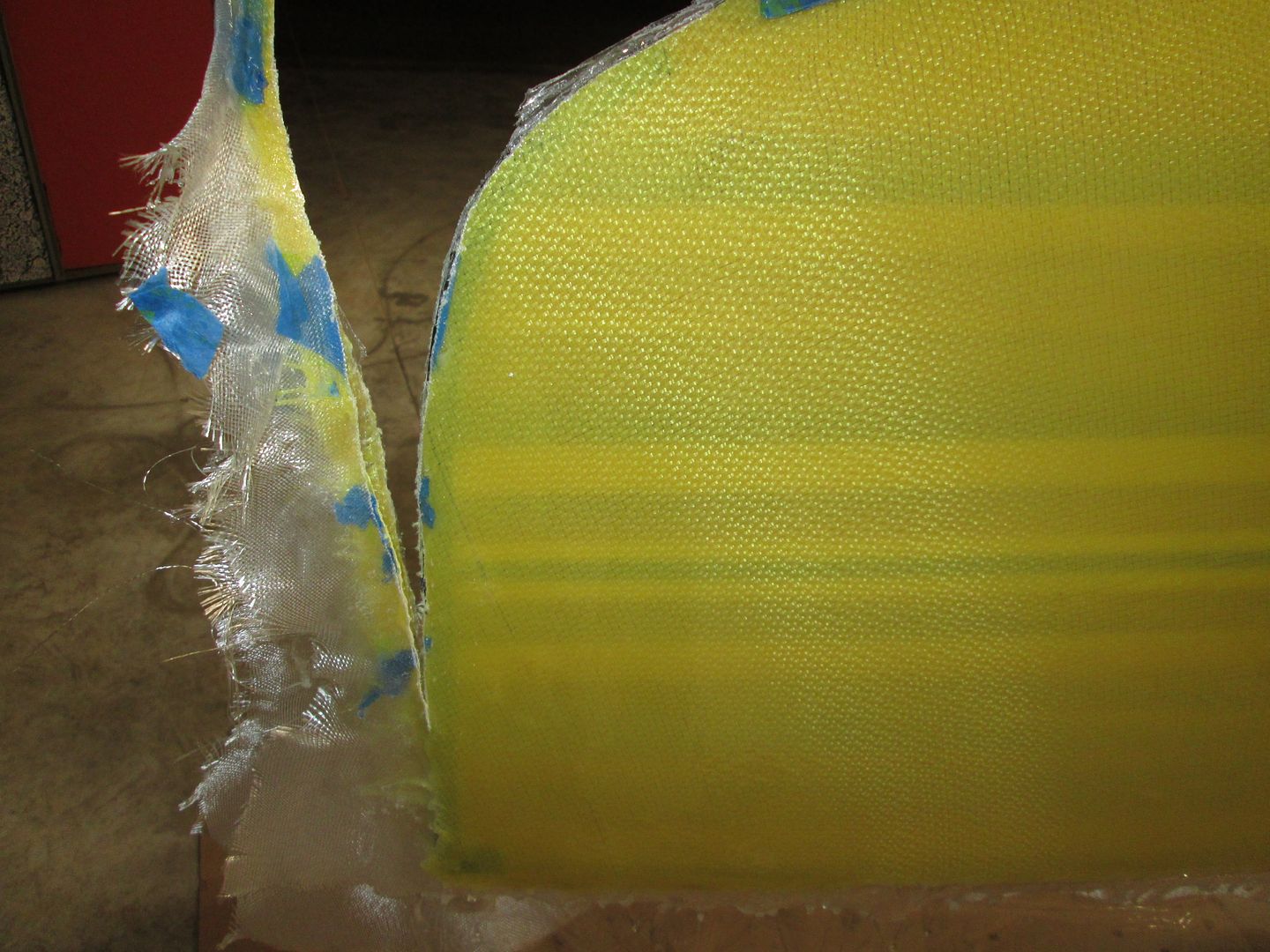

Some pics of the Ellery

Some pics of the Ellery