Stripper: I'd really like to see some pictures of the process of your composite hulls with Divinycell foam.Jim,

Did you reinforce the other side of the foam as well?

I’m in the middle of making a total of 4 carbon/glass/Divinycell hulls. One of the future owners (my nephew) likes those teardrop shaped bulkheads, but we’ll use some excess 1/8” Divinycell for that. I’m curious how you held shape while you (if you) reinforced the back side.

-

Happy Birthday, Nostradamus (1503-1566)! 🔮🌃♐

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Stripper and a Composite Copy

- Thread starter Jim Dodd

- Start date

Two main reasons. Kevlar doesn't sand well. It Fuzzes. Covering it with a layer of E-glass, or S-glass, allows me to sand the hull. Adding extra layers, add stiffness . One layer of Kevlar isn't stiff enough.That is a beautiful boat! Now you've got me thinking of trying a composite after my next build. Something for tripping places like BWCA. Rocks everywhere, and more portaging than I like doing with a stripper. Just got back from a week with my stripper, and now I'll be buffing and recoating varnish, which I expected.

One question that keeps nagging at me. Seems like all the Kevlar surfaces you topped with 4 oz glass, either E or S. Isn't one of the biggest advantages of Kevlar its superior abrasion resistance? If that's the case, why put glass over it?

Good question !

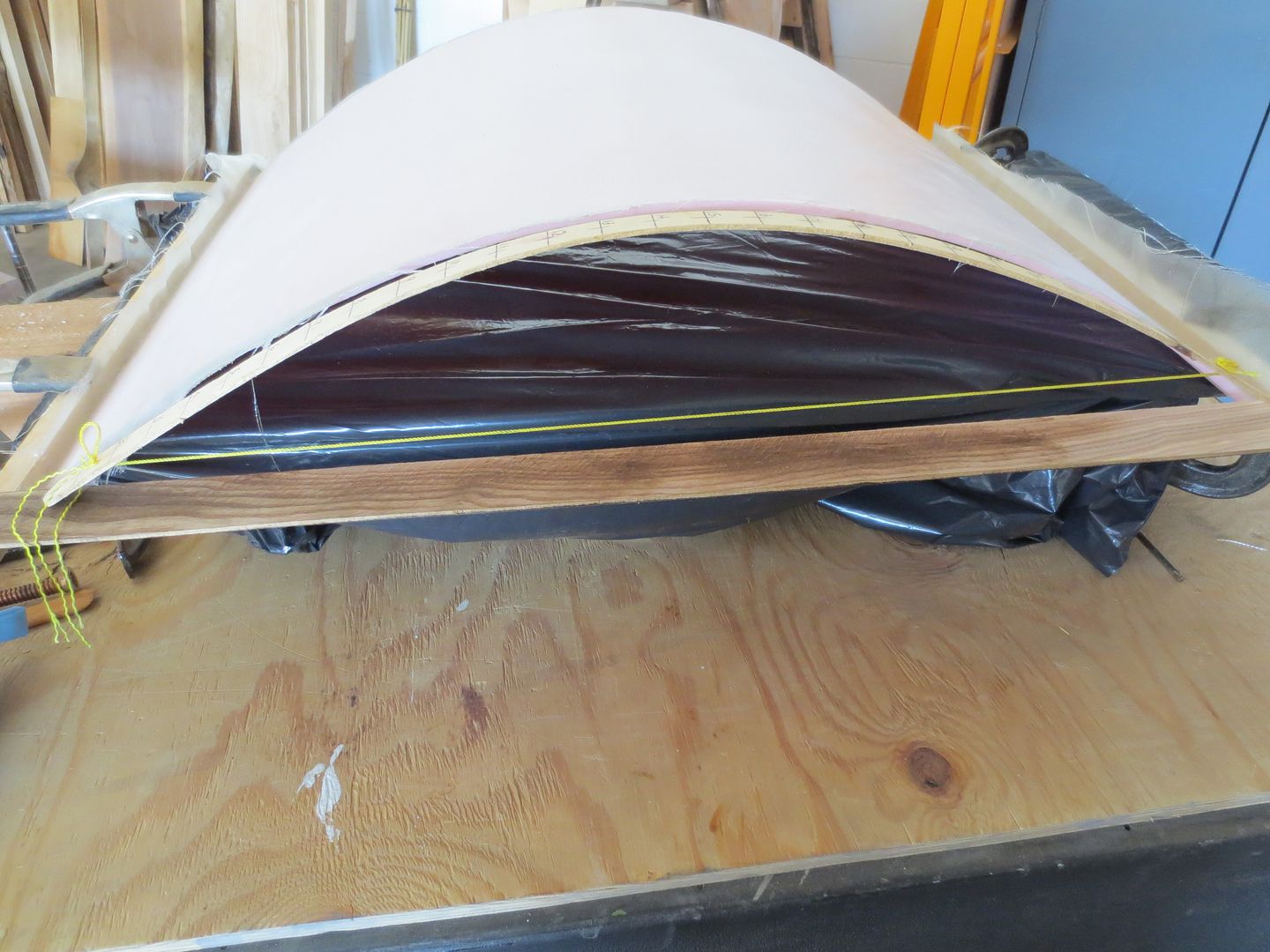

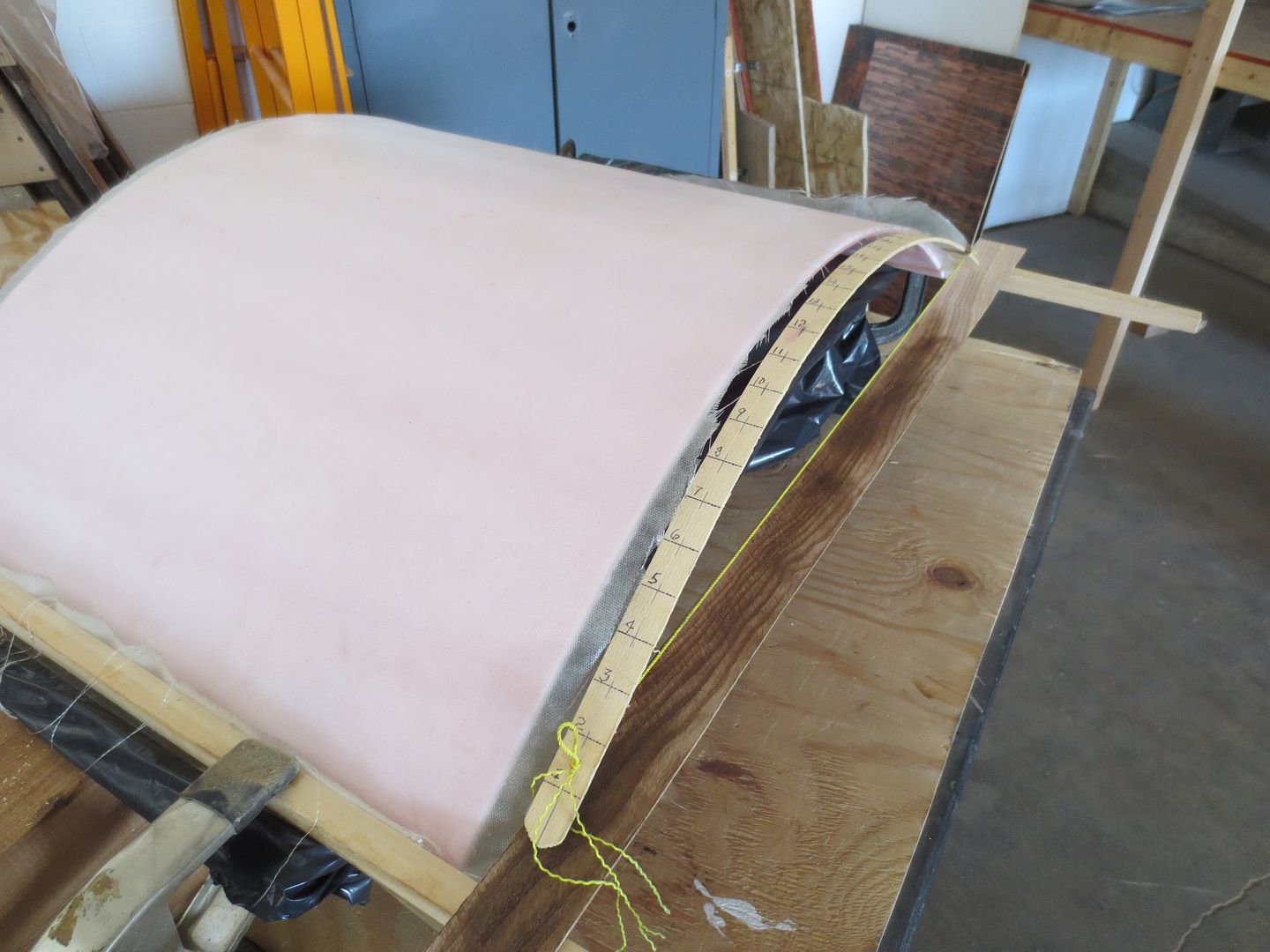

I used Cheap construction foam, instead of Divinycell. The pink foam doesn't flex well, and breaks catastrophically.Stripper: I'd really like to see some pictures of the process of your composite hulls with Divinycell foam.

For flotation chambers how ever it works fine.

Yes, I glassed both side of the flotation chambers. Better safe than sorry.Stripper: I'd really like to see some pictures of the process of your composite hulls with Divinycell foam.

So on this hull, and the composites I've built. One layer of cloth on both sides, a layer of Kevlar, and a final layer of cloth, because again, you can't scrape,

or sand Kevlar.

Here are a few picks from other builds.

I bend the foam to match the curve of my "Story stick "

One question that keeps nagging at me. Seems like all the Kevlar surfaces you topped with 4 oz glass, either E or S. Isn't one of the biggest advantages of Kevlar its superior abrasion resistance? If that's the case, why put glass over it?

Two main reasons. Kevlar doesn't sand well. It Fuzzes. Covering it with a layer of E-glass, or S-glass, allows me to sand the hull. Adding extra layers, add stiffness . One layer of Kevlar isn't stiff enough.

In addition to these reasons, when you bash a canoe onto a rock or hard place, to minimize damage you want a fabric with high compressive strength as your outside layer and high tensile strength as your inside layer. Hence, the outer layer of a composite hull is usually formed of a fabric with high compressive strength. S-glass is strongest in compressive strength; Kevlar is relatively weak. Kevlar is much better at tensile strength, so it is better suited for a lightweight inside layer in a hull laminate. See this thread:

Comparison of S-Glass, E-Glass, Kevlar and Carbon for Canoe Hulls

How do S-glass, E-glass, Kevlar (aramid), and carbon composite fabrics compare in compression strength, tensile strength, stiffness, and weight—and where in a canoe hull should you put each fabric? I've posted the following information, graphs and video buried in the middle of two build threads...

www.canoetripping.net

Finally had time to get back to the Copy.

Installed aluminum gunnels and thwarts.

Boy do I like the installation process! I'm sure I was a lot slower, than a factory trained individual !

No Glue ! No Screws ! Unusual for me !

I started in the middle and worked towards the ends. I couldn't prebend the gunnels, so the thwarts became fulcrums , to pull the ends together at the stems.

Luckily I had end caps, from a Bell canoe, that matched up pretty good !

I put the hull, trimmed, and seats with bolts, on the scale.

38 lbs , 8 lbs lighter thanthe stripper, I used as the mold.

8 lbs is a major improvement !

I know I will appreciate it on the Portage !

Now for varnish, and I'll put her on the water !

Thanks for following along !

If you have questions ?

Let me know !

If you plan to make a copy of your Stripper ?

This is a great method !

Jim

Installed aluminum gunnels and thwarts.

Boy do I like the installation process! I'm sure I was a lot slower, than a factory trained individual !

No Glue ! No Screws ! Unusual for me !

I started in the middle and worked towards the ends. I couldn't prebend the gunnels, so the thwarts became fulcrums , to pull the ends together at the stems.

Luckily I had end caps, from a Bell canoe, that matched up pretty good !

I put the hull, trimmed, and seats with bolts, on the scale.

38 lbs , 8 lbs lighter thanthe stripper, I used as the mold.

8 lbs is a major improvement !

I know I will appreciate it on the Portage !

Now for varnish, and I'll put her on the water !

Thanks for following along !

If you have questions ?

Let me know !

If you plan to make a copy of your Stripper ?

This is a great method !

Jim

Last edited:

Looks sweet, Jim!

Jim,

I don’t want to steal your thread

In a few days I’ll post some pics and descriptions of my latest carbon copy

BTW, your boat is looking great!!

I don’t want to steal your thread

In a few days I’ll post some pics and descriptions of my latest carbon copy

BTW, your boat is looking great!!

- Joined

- Aug 10, 2018

- Messages

- 2,039

- Reaction score

- 3,331

Nice! Looks awesome and, yes, 8 lbs lighter is always appreciated.

Really impressive Jim. Thanks for sharing your method.

Bob

Bob

Maybe I missed it but did you compare weights of the hulls at similar points of the construction process? I'd be curious to know how much weight difference there was in the bare hulls and how much weight difference between the wood and aluminum trim.

As usual the boats look great!

Alan

As usual the boats look great!

Alan

Maybe I missed it but did you compare weights of the hulls at similar points of the construction process? I'd be curious to know how much weight difference there was in the bare hulls and how much weight difference between the wood and aluminum trim.

As usual the boats look great!

Alan

I did weigh, and the Aluminum trim was about 2 lbs lighter.

I was expecting more of a difference.

As for the hulls ? A little math.

The Stripper hull without trim was 33.5 lbs.

The composite, without trim, roughly 27.5 lbs.

My scale is not Official, as it's a Digital fish scale, rated to 50 lbs.

So you can take it for what it's worth.

Jim

Jim:

As expected, awesome looking boat, and great thread. Only down side, now I want to try to follow in your footsteps, but I'm still wobbly on my boat building legs. I am contemplating doing my next build at work, where I have much more room, and then I'd be able to work on it for a couple hours a day in my "down time". If I go that route, I may get crazy and do a project similar to yours: A new cedar strip, followed by a composite copy.

As expected, awesome looking boat, and great thread. Only down side, now I want to try to follow in your footsteps, but I'm still wobbly on my boat building legs. I am contemplating doing my next build at work, where I have much more room, and then I'd be able to work on it for a couple hours a day in my "down time". If I go that route, I may get crazy and do a project similar to yours: A new cedar strip, followed by a composite copy.

The drawback, is the cost of a Kevlar copy. Was lucky to get the Kevlar, for next to nothing. I use more epoxy on it, than the stripper.Jim:

As expected, awesome looking boat, and great thread. Only down side, now I want to try to follow in your footsteps, but I'm still wobbly on my boat building legs. I am contemplating doing my next build at work, where I have much more room, and then I'd be able to work on it for a couple hours a day in my "down time". If I go that route, I may get crazy and do a project similar to yours: A new cedar strip, followed by a composite copy.

It worked for me, as I plan to sell the stripper, leaving me with a lighter canoe for me to play with.

With two canoes, is easier to give one up.

Storage is the next challenge.

It has been fun !

Thanks guys for the positive comments

Here to help !

Jim

I'm a long way from having to worry about storage. I currently have a second floor to a four car garage, that's finished, insulated, and heated. Not being used. I'm considering turning it into a canoe build shop, and adding an outside balcony & second set of stairs for sanding & easier access.

- Joined

- Aug 10, 2018

- Messages

- 2,039

- Reaction score

- 3,331

Best... idea... ever!I'm considering turning it into a canoe build shop, and adding an outside balcony & second set of stairs for sanding & easier access.

Jim:

I'd be happy to help with your storage issues Just let me know when I should bring a trailer down. I can store 10 or so, to free you up some space, and you can get back to building.

Just let me know when I should bring a trailer down. I can store 10 or so, to free you up some space, and you can get back to building.

I'd be happy to help with your storage issues

Very Tempting !!!Jim:

I'd be happy to help with your storage issuesJust let me know when I should bring a trailer down. I can store 10 or so, to free you up some space, and you can get back to building.

I have two solos stored in Ely now.

Two at the Nokomis wood shop.

Seven at my canoe shop.

Eight at my old house.

One in Ames Iowa.

Three Aluminums at my old place. They don't count, because they are outside.

That is a great offer !

What is the licensing requirement in Wisc ?

I Have boats to build !

Dang, Jim: Getting out my calculator, and using high level math, that's 20, not counting the Aluminum canoes. Plus any you've sold/given away No wonder you're so darn good. Personally, that would bother me having so many awesome boats, that I've made, and not enough time to paddle them all.

Wisconsin has no licensing requirements for canoes, or home built boats (I think there's a size limit on home built boats not needing licenses) unless you put a motor on them. I also have a 30' * 48' pole barn at my place in northern WI, 15 minutes from Turtle-Flambeau flowage, another great paddling/fishing destination, though motors are allowed there. There's a guy shows up at a local flea market up there once-twice a summer, with a 6 boat trailer with strippers for sale. All gone in a couple days. I used to think his prices were crazy. Now, I realize I either need to get more efficient, or I'd be making less than McDonalds.

I'd really like to see your "fleet" in person some day. From experience, pictures are nice, but nothing beats up close, touchy-feely.

Wisconsin has no licensing requirements for canoes, or home built boats (I think there's a size limit on home built boats not needing licenses) unless you put a motor on them. I also have a 30' * 48' pole barn at my place in northern WI, 15 minutes from Turtle-Flambeau flowage, another great paddling/fishing destination, though motors are allowed there. There's a guy shows up at a local flea market up there once-twice a summer, with a 6 boat trailer with strippers for sale. All gone in a couple days. I used to think his prices were crazy. Now, I realize I either need to get more efficient, or I'd be making less than McDonalds.

I'd really like to see your "fleet" in person some day. From experience, pictures are nice, but nothing beats up close, touchy-feely.

I've thought about canoe group pic, having them in different places makes it a chore.

Lucky for you ! No licenses . It cost me $400 every three years, at the Court House. They hate to see me come in ! Ha !

Kayaks pay no license here, if they under 13". Most are.

I'd love to make it up your way ! You are more than welcome here ! We might even have time to paddle, after I take you through our shop !

Jim

Lucky for you ! No licenses . It cost me $400 every three years, at the Court House. They hate to see me come in ! Ha !

Kayaks pay no license here, if they under 13". Most are.

I'd love to make it up your way ! You are more than welcome here ! We might even have time to paddle, after I take you through our shop !

Jim

Geez, Iowa needs to get into the 20th century (I know 21st would be asking too much). I have 4 boats to register, but it's all on line. Painless, other than the $. $60 per boat for 3 years. Not bad. You're welcome here any time. My place in Northern WI just takes a few days notice. I get there as much as I can, but it's 4 1/2 hours away, and obligations get in the way some times. Fishing and paddling much better there though.

Similar threads

- Replies

- 78

- Views

- 10K

- Replies

- 2

- Views

- 355