Hi all. I’'ve been ill with a cold for almost a week now plus some business travel. It doesn’'t make for very productive progress. Here'’s where we are…...

I applied the coats of epoxy to the inside and outside of the hull. I found a really nice day (17 deg.) and all went well except for the fruit flies. You'’ll get a chuckle out of this one… I had just finished the exterior of the hull. It looked fantastic. I pulled some stuff out of the garage to have enough room to move around, but didn'’t think about the fact that there were tons of fruit flies now having a hayday in my food recycle bin, because of the really warm weather. I moved it back into the garage and was bombarded by the little buggers. Guess where they went…yep, straight to the epoxy. I spent the next ½ hour tweezing them out of the finish. There were a couple I didn'’t notice until the next day. They’ll sand out though.

Anyways, on to the inwales and decks. If you remember, my outwales sit on top of the hull core with a rabbet machined into them. This means that the inwales have to sit ¼” proud of the top edge of the hull so that they will line up with the outwales once installed. I cut a small piece off the outwale stock to use as my guide when setting these up. Also, I did not want to see any fasteners holding either inwale or outwale in place , so I’m going to fasten inwale with screws first and then epoxy the outwales. I’m doing a dry run with the inwales so that I can line everything up, and don’t have the pressure of the epoxy setting up on me. I’m using steel screws to cut the threads, which will be replaced with brass screws. I predrilled 2 holes into every other scupper shoulder. I thought it would be a little over kill to do every one, especially because these will be epoxied in place. My shoulders are 3” wide, so I have about a 1” space from each end and 1” in the middle. This seems to have worked out just fine.

At the bow and stern, I have these nice little decks to install. They have been cut to the final shape, but not shaped. I’ll get to that in a minute.

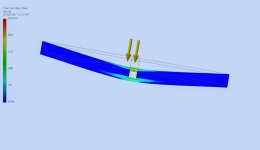

In order for the decks to end up sitting in the correct plane to line up with the inwale and outwale, the underside of the leading edge has to be cut away. My decks are ¾” thick so I had to cut ½” away. The deck will then sit on top of the inner and outer stem bands. I like this look much better than seeing edge grain of the stems. Plus, it wouldn’t work any other way with my gunwale design.

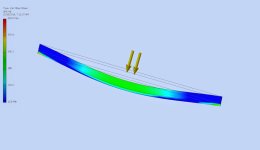

Next, the spearhead deck design calls for the inwale to be cut short of the full length of the boat and fitted into an angled shoulder. The inwales have to be installed in conjunction with the decks in order to test fit and measure for the proper length. With a little finesse, and lots of patience, I think they turned out pretty well so far. The 2 screws at the deck are long enough to go through the inwales and into the deck. They have to be installed on a slight upward angle to catch enough "meat". I hope the pictures show what I’m trying to describe for you.

As you can see, the side view shows how steeply the bow rises compaired to the flatness of the deck. I will now have to shape this to follow the hull line, keeping in mind that I should be proud of the line by ¼”. Just like the inwales.

I hope this seems clear to you. I can take more photos, or give more detail if you want. Just let me know.

So, with inwales and decks temporarily installed, I'’ll set to work on shaping them to suit the lines of the hull. I’ll let you know how it turns out.

Thanks for joining me.

I applied the coats of epoxy to the inside and outside of the hull. I found a really nice day (17 deg.) and all went well except for the fruit flies. You'’ll get a chuckle out of this one… I had just finished the exterior of the hull. It looked fantastic. I pulled some stuff out of the garage to have enough room to move around, but didn'’t think about the fact that there were tons of fruit flies now having a hayday in my food recycle bin, because of the really warm weather. I moved it back into the garage and was bombarded by the little buggers. Guess where they went…yep, straight to the epoxy. I spent the next ½ hour tweezing them out of the finish. There were a couple I didn'’t notice until the next day. They’ll sand out though.

Anyways, on to the inwales and decks. If you remember, my outwales sit on top of the hull core with a rabbet machined into them. This means that the inwales have to sit ¼” proud of the top edge of the hull so that they will line up with the outwales once installed. I cut a small piece off the outwale stock to use as my guide when setting these up. Also, I did not want to see any fasteners holding either inwale or outwale in place , so I’m going to fasten inwale with screws first and then epoxy the outwales. I’m doing a dry run with the inwales so that I can line everything up, and don’t have the pressure of the epoxy setting up on me. I’m using steel screws to cut the threads, which will be replaced with brass screws. I predrilled 2 holes into every other scupper shoulder. I thought it would be a little over kill to do every one, especially because these will be epoxied in place. My shoulders are 3” wide, so I have about a 1” space from each end and 1” in the middle. This seems to have worked out just fine.

At the bow and stern, I have these nice little decks to install. They have been cut to the final shape, but not shaped. I’ll get to that in a minute.

In order for the decks to end up sitting in the correct plane to line up with the inwale and outwale, the underside of the leading edge has to be cut away. My decks are ¾” thick so I had to cut ½” away. The deck will then sit on top of the inner and outer stem bands. I like this look much better than seeing edge grain of the stems. Plus, it wouldn’t work any other way with my gunwale design.

Next, the spearhead deck design calls for the inwale to be cut short of the full length of the boat and fitted into an angled shoulder. The inwales have to be installed in conjunction with the decks in order to test fit and measure for the proper length. With a little finesse, and lots of patience, I think they turned out pretty well so far. The 2 screws at the deck are long enough to go through the inwales and into the deck. They have to be installed on a slight upward angle to catch enough "meat". I hope the pictures show what I’m trying to describe for you.

As you can see, the side view shows how steeply the bow rises compaired to the flatness of the deck. I will now have to shape this to follow the hull line, keeping in mind that I should be proud of the line by ¼”. Just like the inwales.

I hope this seems clear to you. I can take more photos, or give more detail if you want. Just let me know.

So, with inwales and decks temporarily installed, I'’ll set to work on shaping them to suit the lines of the hull. I’ll let you know how it turns out.

Thanks for joining me.

Last edited: