OK ! Here is how I did my 1/8" strip bottom, and it has worked great.

I would do it the same way with your foam !

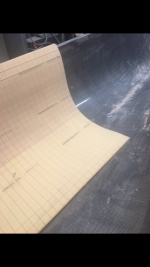

First tape (2") around the perimeter of your foam,as it lays in the hull., You want it to be put back the same place, when you epoxy it

Scuff the bottom of the hull lightly with course sand paper, within the the taped area.

Support the hull !!! I failed to do this Once ! Spent a lot of time repairing ! If your gunnels are on, this will help some too !

I mixed epoxy ( two 9 oz batches) and cabo o sil (The light fluffy stuff.) Spread it out, again inside the perimeter of the tape.

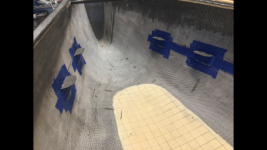

Lay your foam on top ! Cover with plastic ! I used 3 mil plastic. Make sure to use enough plastic to run up and over the sides of the hull.

Fill this plastic cover with sand. The weight of the sand will hold the foam against the epoxy. Poor Man's Vacumm bagging !

How much Sand ? 2 - 300 # is about what I used on my solos.

A day or two later (Later is better) scupe out the sand and lift out the plastic, and you are done, except feather the edge of your foam before adding your layer of carbon, or what ever !

Mix ? How much epoxy do you need ? I used 18 oz for my solos. Squeeze out wasn't a problem, but it seemed like enough epoxy to do the job. Divinicell should show better if you had enough ! It will soak up a lot more resin because of all the slits in it. For your hull I'd mix maybe 3, 9 oz batches.

It worked for me, and I'll do it again

Jim