Awesome meeting up with Jim and Steve last week, talking canoes and paddling theirs! I am already thinking about a solo build...

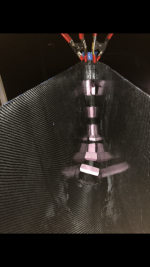

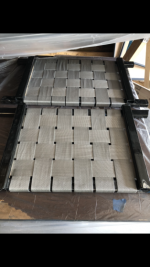

Anyway, we made a serious mess in the garage on Saturday laying up the canoe. To recap, we went with the shrink wrap film as a barrier on an existing 18 foot Jensen. I added about 5/8 inch freeboard around the hull and even more in the bow. Layup is 5.7 oz carbon-Innegra hybrid, 6 oz IM carbon fiber, 3.16 oz style 120 E-glass, 4 oz S glass football. We managed to squeeze an s-glass skid plate while we were at it too. The whole hull was covered in peelply at the end.

What went well:

We sealed the bow end and left the stern open to pull it off the mold. The hull came off pretty easily and saved the hassle of sealing an end. I am laying up a stem piece now that will be epoxied and inserted to the other end when cured.

These shears! I picked them up at the Home Depot and they cut Innegra like a champ. One side is serrated, which grips the material well. They even trimmed the entire hull post-cure with minimal blisters.

The Carbon Innegra fabric. It is a bit messier than pure carbon fiber but is easier to tell when it wets out and it did not seem to soak up a ridiculous amount of resin like I had read.

What did not go so well:

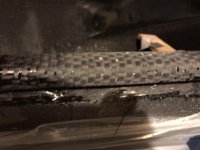

The carbon fiber is only 49 inches, about 3 inches too short around the middle. Partial pieces are a PITA and that part looks ugly.

Style 120 fiberglass. This stuff is so hard to wet out, it is almost as tightly woven as peel ply. My brothers gf commented accurately that the canoe looked like a dairy cow during this part. There are several spots throughout the hull. Hopefully it looks better after the full coat.

Next step is to seal up the stern end and figure out a method for the carbon-foam gunwales.

Anyway, we made a serious mess in the garage on Saturday laying up the canoe. To recap, we went with the shrink wrap film as a barrier on an existing 18 foot Jensen. I added about 5/8 inch freeboard around the hull and even more in the bow. Layup is 5.7 oz carbon-Innegra hybrid, 6 oz IM carbon fiber, 3.16 oz style 120 E-glass, 4 oz S glass football. We managed to squeeze an s-glass skid plate while we were at it too. The whole hull was covered in peelply at the end.

What went well:

We sealed the bow end and left the stern open to pull it off the mold. The hull came off pretty easily and saved the hassle of sealing an end. I am laying up a stem piece now that will be epoxied and inserted to the other end when cured.

These shears! I picked them up at the Home Depot and they cut Innegra like a champ. One side is serrated, which grips the material well. They even trimmed the entire hull post-cure with minimal blisters.

The Carbon Innegra fabric. It is a bit messier than pure carbon fiber but is easier to tell when it wets out and it did not seem to soak up a ridiculous amount of resin like I had read.

What did not go so well:

The carbon fiber is only 49 inches, about 3 inches too short around the middle. Partial pieces are a PITA and that part looks ugly.

Style 120 fiberglass. This stuff is so hard to wet out, it is almost as tightly woven as peel ply. My brothers gf commented accurately that the canoe looked like a dairy cow during this part. There are several spots throughout the hull. Hopefully it looks better after the full coat.

Next step is to seal up the stern end and figure out a method for the carbon-foam gunwales.