I know I've covered this before ! But I picked up a good deal at Menard's on a 15 amp. Skilsaw brand Skilsaw. This is in no way is an endorsement, but at $50 for a 15 amp saw, I thought I would put this up !

First I want to put up a Disclaimer, as I don't want anyone to get hurt, and come back to me on it ! So do this at your own risk ! Read and follow the Manufacturers manual !.

I have cut strips using this method for all my canoes, as well as strips for many others. This technique has evolved , so I want to share it here. The quality of strips is great ! The strips are so uniform, that Planing is totally unnecessary ! Making the cost minimal, allowing the first time builder, to save a lot of money ! According to my latest comparison. A Builder can easily save at least a $1,000, on his First build !

Here is the saw set up for cutting strips that I use. It's set for 1/4" strips, but I will change that later to thinner strips.

Note The Vise grip. It is just there to serve as a handle while cutting strips this gives great control, and keeps my hand away from the blade, while cutting.

By the Way, I use this same set up for cutting my gunnels. I actually have several saws set for different widths strips.

The clamps are simple 2" C-clamps.

Also note the Diablo blade. 24 teeth does a great job. and a blade with more teeth is just harder for the saw to turn. Again I don't intend this post as an endorsement ! About any saw and blade combination will work, but I recommend 13 amps or more ! I burnt my first two Skilsaws out, because they were only 11 amps !

Looking over this saw when I unboxed it, I noted right away, it was made in China, there was a little end play in the shaft, and it was heavy ! On the Plus side, it has a long cord, and a cast base, hoping this will make it glide on the Cedar planks easier !

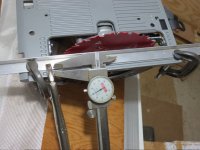

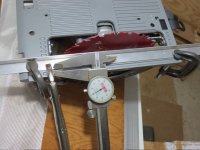

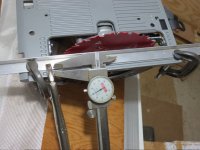

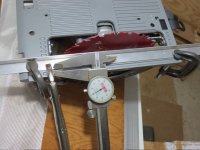

Note the caliper below the saw. A tape measure, is not accurate enough for me, but use the best measuring tool you can find for this, A combination T-square will work also .

Be sure the saw is unplugged when ever you are adjusting ! Be careful of the blade, as it is sharp !

Start by lowering the blade, so it's at the deepest cutting depth. Then measure the gap between the blade and fence, The front side, and the back side. They should be the same. The true test is cutting a scrap strip. After you are satisfied with the measurements, tighten the C-clamps and attach vise grip.

On several of my saws, I'm able to use the Visegrip as the front clamp. Not this one, because of the Cast base.

Note the Aluminum angle clamped to the base. It is 1/16" thick, 3/4" x 1/2"x 16" long.

In the past, I used thicker angle, 3/4' x 3/4" and cut the edge that runs against the plank to 5/8" . I prefer the thicker angle, but it's a pain to cut them down.

Set the cutting depth to about a 1/4" below the thickness of the plank you are cutting.

I haven't put this saw to the test yet, but I will soon !

If you have any questions or comments please feel free to post !

Jim

First I want to put up a Disclaimer, as I don't want anyone to get hurt, and come back to me on it ! So do this at your own risk ! Read and follow the Manufacturers manual !.

I have cut strips using this method for all my canoes, as well as strips for many others. This technique has evolved , so I want to share it here. The quality of strips is great ! The strips are so uniform, that Planing is totally unnecessary ! Making the cost minimal, allowing the first time builder, to save a lot of money ! According to my latest comparison. A Builder can easily save at least a $1,000, on his First build !

Here is the saw set up for cutting strips that I use. It's set for 1/4" strips, but I will change that later to thinner strips.

Note The Vise grip. It is just there to serve as a handle while cutting strips this gives great control, and keeps my hand away from the blade, while cutting.

By the Way, I use this same set up for cutting my gunnels. I actually have several saws set for different widths strips.

The clamps are simple 2" C-clamps.

Also note the Diablo blade. 24 teeth does a great job. and a blade with more teeth is just harder for the saw to turn. Again I don't intend this post as an endorsement ! About any saw and blade combination will work, but I recommend 13 amps or more ! I burnt my first two Skilsaws out, because they were only 11 amps !

Looking over this saw when I unboxed it, I noted right away, it was made in China, there was a little end play in the shaft, and it was heavy ! On the Plus side, it has a long cord, and a cast base, hoping this will make it glide on the Cedar planks easier !

Note the caliper below the saw. A tape measure, is not accurate enough for me, but use the best measuring tool you can find for this, A combination T-square will work also .

Be sure the saw is unplugged when ever you are adjusting ! Be careful of the blade, as it is sharp !

Start by lowering the blade, so it's at the deepest cutting depth. Then measure the gap between the blade and fence, The front side, and the back side. They should be the same. The true test is cutting a scrap strip. After you are satisfied with the measurements, tighten the C-clamps and attach vise grip.

On several of my saws, I'm able to use the Visegrip as the front clamp. Not this one, because of the Cast base.

Note the Aluminum angle clamped to the base. It is 1/16" thick, 3/4" x 1/2"x 16" long.

In the past, I used thicker angle, 3/4' x 3/4" and cut the edge that runs against the plank to 5/8" . I prefer the thicker angle, but it's a pain to cut them down.

Set the cutting depth to about a 1/4" below the thickness of the plank you are cutting.

I haven't put this saw to the test yet, but I will soon !

If you have any questions or comments please feel free to post !

Jim

Last edited: