OK ! I guess I'm the guy that seal coats ! But I'm going to go with the majority THIS time ! HA ! If you have the staple holes filled, as well as any voids ? Skip the seal coat.

Let US know how it goes. You might talk some sense into me . HA

Cruiser brought up some great points, as you are about to glass ! A good extra hand, especially for the wet out is good !

I'd like to offer some tips, that I believe will save you some headache.

Warm your working area, for this time of year, as high as you can get it. Awhile back I had my shop at near 90 F. You don't need it that hot, but 70 or above would be good.

While applying the wet out coat, lower the temp at least a few degrees. This should nearly eliminate the Outgassing of air from stapleholes, or small gaps.

I let the wet out coat set. Past the tacky stage. DON"T WALK AWAY FROM IT, while the resin is setting in this stage, is where most of your troubles will appear.

Stay around it for a couple hours while the resin sets. I time this so I'm done in the evening.

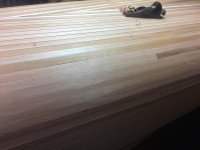

The next morning I start applying fill coats. Here is where it gets tricky.

The wet out coat leaves a textured surface, that's great for holding resin. Once you apply the first Fill coat, to the cloth, wait about an hour, and apply the second coat. Your first Fill coat will still be tacky, and will hold the next coat without runs. This is a big benefit, later ! I hate runs.

Second coat on ? Again wait an hour and apply Third Fill coat..

Depending on the resin you are using, three fill coats might be enough. If you see ANY resemblance of the weave,is visible on the sides, go with another fill coat. When I was using System Three's Clear Coat, I sometimes need 5 fill coats !

One word on fill coats ! One extra fill coat, is way better than not enough !!!

This technic eliminates any sanding between coats, and is recommended by System Three. I've used it on nearly all my canoes !

I'd love to be there to help !

This all leads to the my next question. Most everyone knows, wait for it !....... Are you going to double layer the bottom ?

Jim