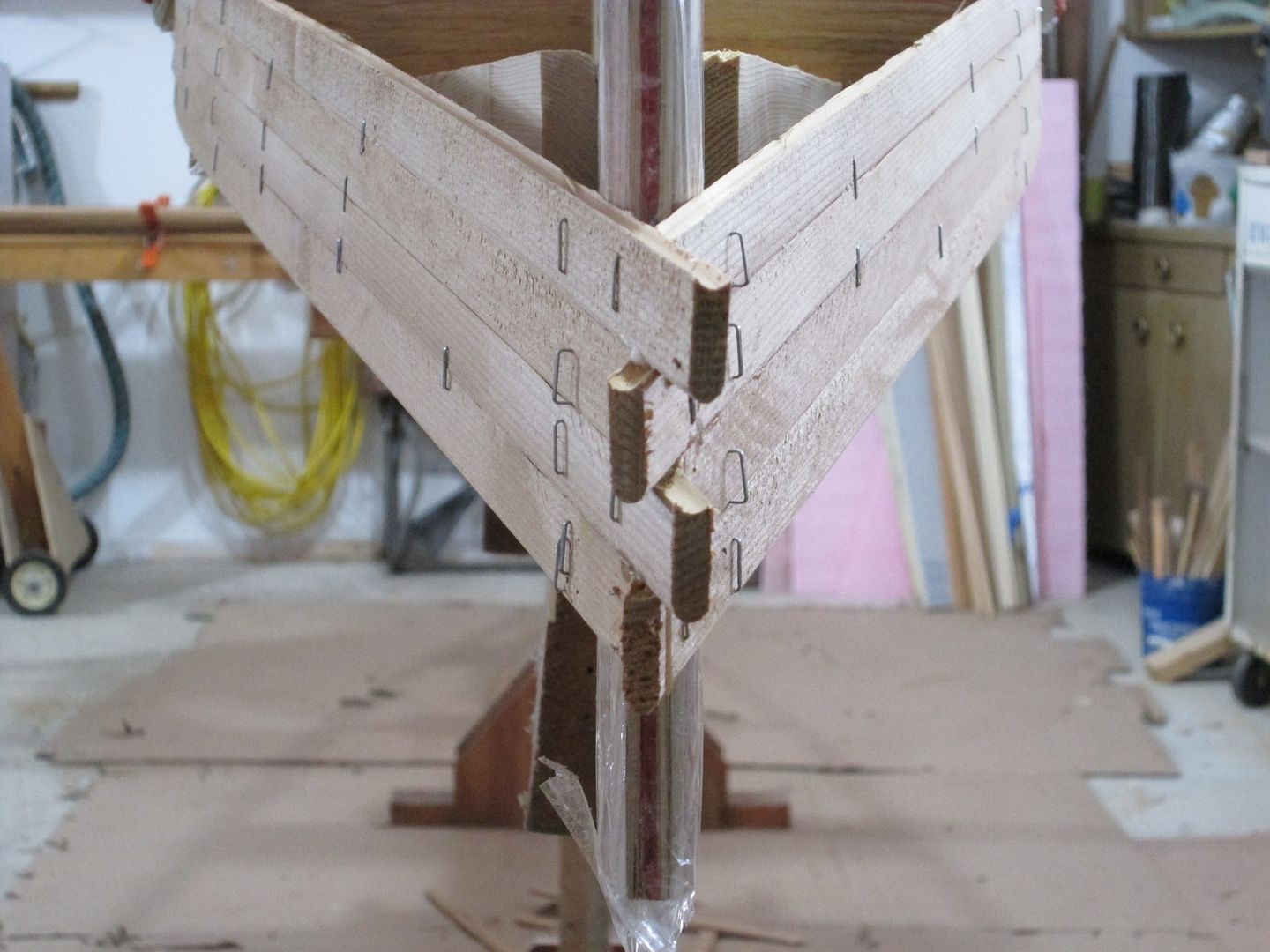

I see you are not alternating stripping side to side. I've always alternated ,that way the ends of the strips interlock. I also did cove up, might not work as well with cove down.

A gain small thing ! Your doing fine !

Jim

A gain small thing ! Your doing fine !

Jim