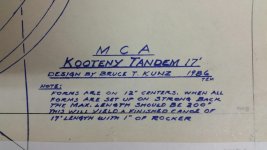

Curious, who designed your Kootenay ?

I would definitely add support to the stem forms ! As Stripperguy points out a triangular support should work !

Your tapering looks good, except at the top, I would add a slight taper there as well.

The Kootenay stem forms can get stuck, because of the recurve. You have used plastic tape, and that's the best that I have found, but I'd be tempted to add another layer, or two ! Over the years, I've had to pry a few stem forms out. Scary to say the least ! But plastic tape seems a lot better.

You've got a great start !

A few pics.

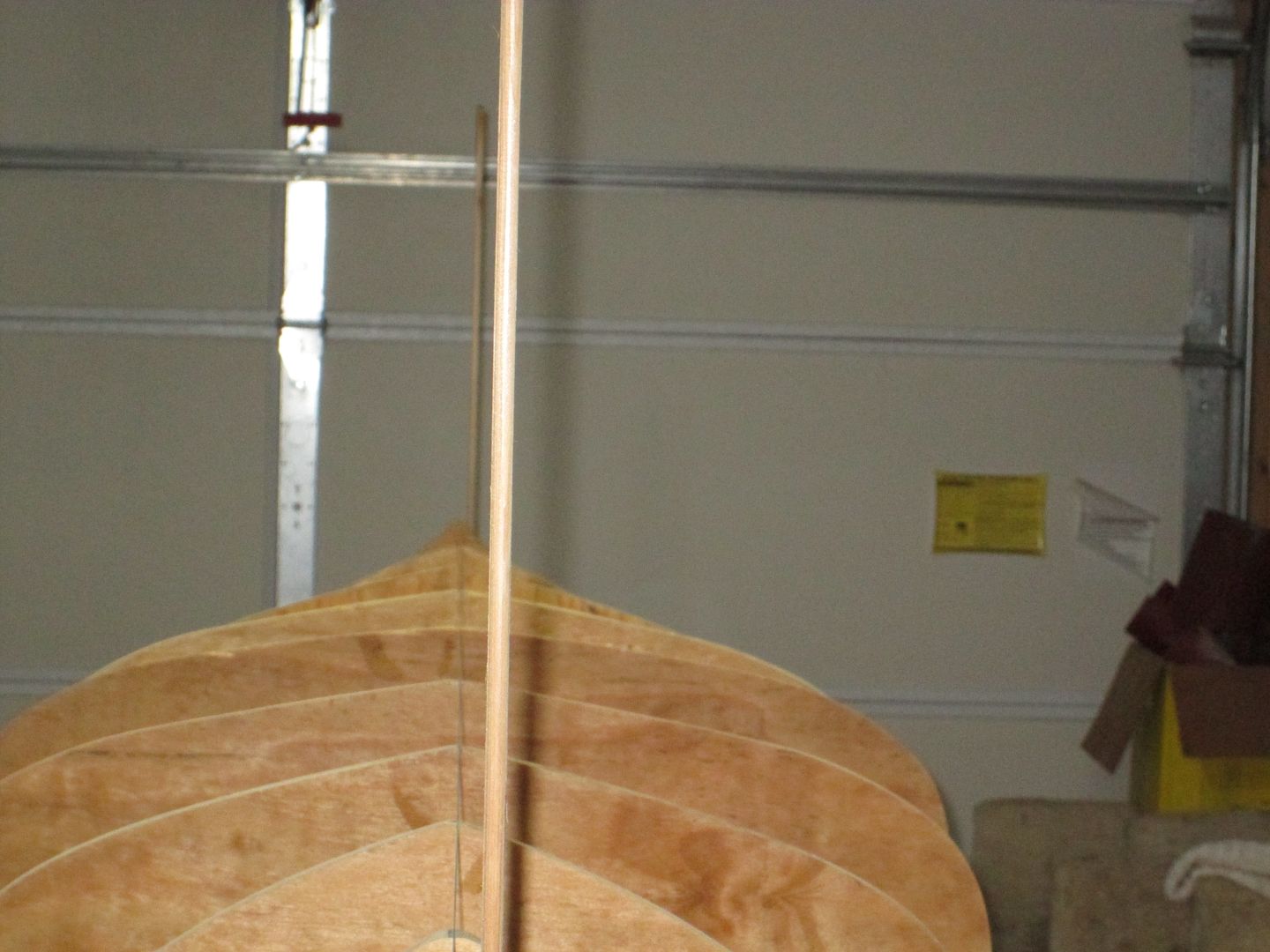

Sight strips stapled to the stem forms to check alignment while building. I leave these on, until i'm about half way up the side, or until they start getting in the way.

How I butt join my strips right on the hull. A 2" spring clamp allows you enough room to slip the next strip in. The bead and coves hold everything in place, and you just keep on stripping.

This pic shows the taper on the stem form. In this case it's a little too much, at the top, but ! it worked. You just want to bevel it enough so the strip has a flat place to lay on. A fairing stick, or scrap strip laid on the forms will tell you how much taper you need.

Hope this helps !

Jim