-

Happy Birthday, Bill Mason (1929-1988)! 🎨📽️🛶

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

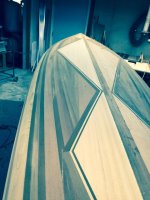

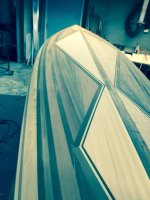

Freedom 17 Strip build

- Thread starter wysedav

- Start date

Wowee! Looking forward to seeing it fully planked!

I had a good amount of time to work on the canoe so I made decent progress...gotta love snow days. Funny I think I make good progress in 4-5 hrs I finished the diamonds, and filled in about 8 strips. I think Alan or Mem would have the side done by now. I appreciate the positive comments, especially coming from you folks knowing the skills you have.

Robin-The cuts don't effect the strength of the composite much if at all, the stiffness really comes from the outer fiberglass skins. The strip kayak builders do it all the time with no ill effects. I think stripper guy went into detail about the structural mechanics of a composite in one of his posts. I can try to answer in detail if you still have any unanswered questions.

Robin-The cuts don't effect the strength of the composite much if at all, the stiffness really comes from the outer fiberglass skins. The strip kayak builders do it all the time with no ill effects. I think stripper guy went into detail about the structural mechanics of a composite in one of his posts. I can try to answer in detail if you still have any unanswered questions.

Not to detract from Dave's artistic expressions, but here's a short description for Robin (disclaimer: I don't know your background, excuse me if I speak below or above you)

The glass/resin layers provide tremendous tensile strength, minor compressive strength. When a load is applied to the hull from the outside, as when riding up over a rock or log, each surface of the hull sees a different type of load.

The outside experiences a compressive load,

the inside experiences a tensile load,

the wood in between sees a shear load.

The inside of the hull deforms and tries to stretch, while the outside tries to accommodate.

As long as the wood does not fail in shear, all is good.

For all of the above to play well together requires a good bond between the glass and the wood, thankfully epoxy resin is a great adhesive.

For a given layup, the hull strength is a function of the geometry and the individual contributions of the resin and glass.

For a simple composite beam, if you double the width of the beam, you double the strength, a linear relationship.

A simply supported composite beam that is twice as long as another, will be 4 times weaker, an inverse square relationship.

That same simply supported composite beam, if made twice as thick, will be 8 times stronger, a cubic relationship.

So, it follows, put the strongest glass on the inside, and make the hull a bit thicker if you need high strength.

Ignoring geometry (curved vs flat surfaces) everything else is a matter of aesthetics and abrasion resistance.

Lastly,

Dave, it's looking great!! Nice patterns...

The glass/resin layers provide tremendous tensile strength, minor compressive strength. When a load is applied to the hull from the outside, as when riding up over a rock or log, each surface of the hull sees a different type of load.

The outside experiences a compressive load,

the inside experiences a tensile load,

the wood in between sees a shear load.

The inside of the hull deforms and tries to stretch, while the outside tries to accommodate.

As long as the wood does not fail in shear, all is good.

For all of the above to play well together requires a good bond between the glass and the wood, thankfully epoxy resin is a great adhesive.

For a given layup, the hull strength is a function of the geometry and the individual contributions of the resin and glass.

For a simple composite beam, if you double the width of the beam, you double the strength, a linear relationship.

A simply supported composite beam that is twice as long as another, will be 4 times weaker, an inverse square relationship.

That same simply supported composite beam, if made twice as thick, will be 8 times stronger, a cubic relationship.

So, it follows, put the strongest glass on the inside, and make the hull a bit thicker if you need high strength.

Ignoring geometry (curved vs flat surfaces) everything else is a matter of aesthetics and abrasion resistance.

Lastly,

Dave, it's looking great!! Nice patterns...

Thanks Dave and SG for the explanation. After I asked, I thought a while about it and figured that if it weakened it, you wouldn't do it.

Anyway, sure looks nice now and after your finished I imagine it will really shine. Nice workmanship!

Anyway, sure looks nice now and after your finished I imagine it will really shine. Nice workmanship!

Now here, is a man, with the utmost of patience.

Wow, that's looking great! Is the angle of the diamonds consistent enough that you can set up some sort of jig to cut the end of the strip that will butt into it, negating the need to custom fit both ends?

Alan

Alan

Not a single staple was harmed during this build.

Incredible Dave. The selection of wood was already impressive, but this marquetry effect is, well, incredible.

Awesome!

Impressive! Very original approach, I like it.

Very Snazzy! That's one very cool canoe! Too bad the hull has to be underwater when you paddle!

Similar threads

- Replies

- 10

- Views

- 512

- Replies

- 75

- Views

- 3K

- Replies

- 25

- Views

- 2K

- Replies

- 15

- Views

- 893