Of course I didn't ask anybody for help, but that's just how I am.

How old are you? I'm starting to think we might have been separated at birth.

Alan

Of course I didn't ask anybody for help, but that's just how I am.

How old are you? I'm starting to think we might have been separated at birth.

Alan

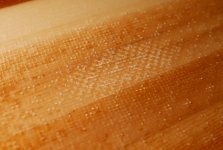

In retrospect, rounding off that knuckle a bit would have helped the glass lay down.[/qoute]

It won't hurt anything but that should have been rounded over. A sharp edge is more prone to damage and also harder on the knuckles. Rounding it over helps the fiberglass lay nicely too.

Foxy looking canoe!

Alan

Look awesome... An other thing you can do with "skid plate", is to hold them on the boat oversized a bit( you can use well stretched saran wrap between the boat and the skid plate) and when totally cured, take it off, grind/trime the edge like you want and epoxy back in place!

Mind you I never tried it, but it works for other area of a damage boat to make a good patch that will fit a gapping hole in the canoe.

OK.

I'm trying to catch up on this tread, As I've been chained up at the Wife's house all day.

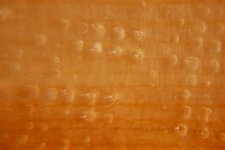

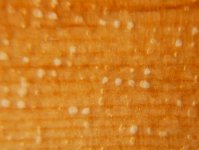

I'm no expert but those pin holes don't resemble out gassing to me. They aren't over staple holes, or along a seam.

Did you have air bubbles when you seal coated ?

The temperature of the epoxy is kinda critical. Did you warm it up any?

In the Winter I warm each batch with a hair dryer as I mix. If the resin is cold, air could have been trapped in the resin while you were mixing.

A contaminate is also a possibility. What cups did you use to mix resin in ?

I know a lot of questions, but by tracking it down, we can all learn from your misfortune.

Can you go through your method of mixing and application of the resin ? How long between fill coats did you wait ?

Thanks Mark !

Jim

Yes, nice and rugged, and gorgeous! Where do you live? That Idaho trip looked absolutely amazing.

The woodworking teacher at our school is full of little pearls of wisdom. He used some of my epoxy to seal a table top he had built. After he had put it on, he took out a blow torch and lightly skimmed the surface. I asked him what he was doing. He claimed that applying heat to the fresh epoxy got rid of any bubbles. I have never tried it, but his seal coat was immaculate.