-

Happy National Garlic Day! 🧄🚫🧛🏼♂️

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's happening in your shop this winter?

- Thread starter Alan Gage

- Start date

Nice simple locking system also.

Alan, I thought of a couple of improvements for your fabric storage setup. Measurement marks on the table to make it easy to pull the correct amount off the role . And an outfeed reel, that way the fabric can be brought over and rolled onto the boat while crease free and without dragging on the floor.

Alan, I thought of a couple of improvements for your fabric storage setup. Measurement marks on the table to make it easy to pull the correct amount off the role . And an outfeed reel, that way the fabric can be brought over and rolled onto the boat while crease free and without dragging on the floor.

Measurements on the table, I like that idea. And an outfeed reel, that sounds like a great idea too! Probably wouldn't have to be attached to the table. It should be easy enough to keep a cardboard tube around and roll it up by hand.

Nice ! I see a couple of empty bars ! Must be saving them for some Innegra, and vacuum bagging stuff !?

Hopefully there will always be room for one or two more rolls, otherwise I didn't make it big enough! The vacuum bagging stuff and peel ply are already up there. Some of the rolls are duplicates (partial rolls) but soon there will be Kevlar to add.

Nice simple locking system also.

Seems I always gravitate back towards simple. The whole time I was building I was thinking about what to do for a latch with some fairly elaborate ideas that got nixed for that very reason. But when it came time I started looking around the shop for ideas and found a scrap piece of 3/8" aluminum rod. Put if over the edge of a board to bend it 90* for a handle, cut it to length, and drilled a couple holes. Simple yet effective.

Now I just need to finish cleaning up the rest of the shop so I can put this new cabinet to use!

Alan

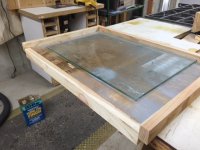

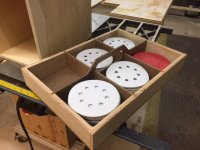

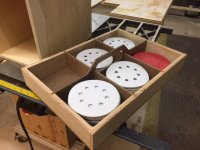

I just got started on a sand paper storage box. It will have a pull out tray that will hold various 5" hook and loop grits, slots to hold full sheets and a side compartment to hold sharpening stones and jigs. The top will be removable with a glass inset so I have a nice setup for sharpening with sandpaper. Here's where I'm at so far...

Once this is finished I'm going to start a solo canoe and maybe a paddle or two.

Once this is finished I'm going to start a solo canoe and maybe a paddle or two.

Ah yes, 'Scary Sharp', I went to the dump and found 50+ sheets of 10 x 16 x 3/16" plate glass and have 2 complete double sets from 80 to 2000 grit.

I need a box like that for work, their disks are everywhere. Great job and look forward to seeing it completed.

I need a box like that for work, their disks are everywhere. Great job and look forward to seeing it completed.

G

Guest

Guest

I'm going to be progressively sanding the many scratches in the hull of my Colden Flashfire 400to 1000 baper wet, then buff it. Never done this-advice welcome.

Turtle

Turtle

I use a soft, flexible sanding block with 1/4 sheets of waterproof paper. Actually the "sanding block" I usually use is a sanding sponge, made by 3M and others, around which I simply wrap the paper. The sanding sponges can also be cut into smaller sized if needed and that may be the case if you need to sand between the shoulder of the recurved tumblehome and the gunwale.

I have found that 3 M paper is probably the best but there are other good brands such as Norton. If you have a lot of scratches, I would probably start with something coarser than 400 grit. 180 grit waterproof paper can usually be easily found and you can certainly use dry paper for the first step as well.

I like to keep the paper and hull good and wet, either spraying the hull repeatedly with a garden hose or dipping the paper in a bucket of water to which a drop or two of dish washing detergent has been added. A hose works great to get the sanding grit and dust off as you go. If you are working in an environment where you need to be a bit neater, you can use a spray bottle filled with water to which a drop of detergent has been added.

The coarser grits will, of course, dull the sheen of the gel coat and leave swirl marks. The finer grits will remove the sanding marks. I personally like to go down to either 1500 or 2000 grit. If you have trouble finding paper this fine at the hardware store, look in the auto body refinishing section of your local auto parts store.

I have had good luck using 3M Finesse-It II glaze and a low speed automotive buffer with a soft bonnet:

http://www.jamestowndistributors.com/userportal/show_product.do?pid=625

There are many other good polishing compounds and buffing compounds that will work. It is best to use the glaze in the shade when it is not too hot, and apply it to relatively small areas at a time before buffing to avoid it drying on the hull surface.

I have found that 3 M paper is probably the best but there are other good brands such as Norton. If you have a lot of scratches, I would probably start with something coarser than 400 grit. 180 grit waterproof paper can usually be easily found and you can certainly use dry paper for the first step as well.

I like to keep the paper and hull good and wet, either spraying the hull repeatedly with a garden hose or dipping the paper in a bucket of water to which a drop or two of dish washing detergent has been added. A hose works great to get the sanding grit and dust off as you go. If you are working in an environment where you need to be a bit neater, you can use a spray bottle filled with water to which a drop of detergent has been added.

The coarser grits will, of course, dull the sheen of the gel coat and leave swirl marks. The finer grits will remove the sanding marks. I personally like to go down to either 1500 or 2000 grit. If you have trouble finding paper this fine at the hardware store, look in the auto body refinishing section of your local auto parts store.

I have had good luck using 3M Finesse-It II glaze and a low speed automotive buffer with a soft bonnet:

http://www.jamestowndistributors.com/userportal/show_product.do?pid=625

There are many other good polishing compounds and buffing compounds that will work. It is best to use the glaze in the shade when it is not too hot, and apply it to relatively small areas at a time before buffing to avoid it drying on the hull surface.

Oops not that great at adding pictures with my iPad. Basically the top isjust set on the box, lift up the front to pull out the tray. The glass gets glued to the underside when I want to use it I take it off flip it over and put it on the bench the lip in the back acts as a hook to keep it from moving around while sharpening.

Mostly knives happening in my work shop this winter. I need to make a better sheath for my Husqvarna forest axe, which I love using by the way. Repair some tripping gear. And,,,,,,being they are legal in my neck of the woods, I plan on designing and making a automatic knife (switch blade). Dave

Wysedave

Years ago I found a trick, but must confessed have never used.

Take some small wood dowels, the same size as the holes in you ROS sand paper. Insert them in to a small scrap piece of plywood, in the same pattern as you sandpaper discs. Stack your paper on these dowels. The neat thing about this trick, is not only will it organize your paper, but when you need a disc, simply set your ROS on the aligned dowels, and the discs will match the ROS holes.

Jim

Years ago I found a trick, but must confessed have never used.

Take some small wood dowels, the same size as the holes in you ROS sand paper. Insert them in to a small scrap piece of plywood, in the same pattern as you sandpaper discs. Stack your paper on these dowels. The neat thing about this trick, is not only will it organize your paper, but when you need a disc, simply set your ROS on the aligned dowels, and the discs will match the ROS holes.

Jim

Just picked up this canoe today. Guy said it was an "Allagash" (17'2"), I weighed it, UGH, 77lbs, might be Polylink? It's a V bottom. hull is in good shape except for strange looking skid plates and an interior patch in one end, nice babiche seats, needs new inwales/gunnels and decks and one thwart.

Good winter project.

Good winter project.

G

Guest

Guest

Hmmmm. Which shop?

I am happily planning for a long shop session in North Carolina. A friend’s shop, but one with plentiful tool and lots of projects. A few days of incommunicado shop heaven down a long dirt road in the wild, a cypress swamp or coastal trip, more shop time, more paddle time.

I always come home with more projects than I left with. Sounds about perfect.

I am happily planning for a long shop session in North Carolina. A friend’s shop, but one with plentiful tool and lots of projects. A few days of incommunicado shop heaven down a long dirt road in the wild, a cypress swamp or coastal trip, more shop time, more paddle time.

I always come home with more projects than I left with. Sounds about perfect.

G

Guest

Guest

Just picked up this canoe today. Guy said it was an "Allagash" (17'2"), I weighed it, UGH, 77lbs, might be Polylink? It's a V bottom. hull is in good shape except for strange looking skid plates and an interior patch in one end, nice babiche seats, needs new inwales/gunnels and decks and one thwart.

Robin, did you search the HIN for a manufacturer. “Allagash” is certainly in the race for the most overused canoe model name. Someone. Stowe had a dozen models monikered “Allagash” something, although those were all composite canoes.

Curious what it is. That length in beefy, old school Royalex could easily be near 80 lbs.

- Joined

- Mar 20, 2013

- Messages

- 3,356

- Reaction score

- 483

Just picked up this canoe today. Guy said it was an "Allagash" (17'2"), I weighed it, UGH, 77lbs, might be Polylink? It's a V bottom. hull is in good shape except for strange looking skid plates and an interior patch in one end, nice babiche seats, needs new inwales/gunnels and decks and one thwart.

Good winter project.

That sure look like a Royalex hull, colour, shine, or lack of it. I'm almost sure it is a Rx hull!!

I'll check tomorrow for more hints. Thanks

The skid plates are a give away...I'd say it's old school royalex, it's difficult to get anything to stick to poly, and really why bother, when the poly boat wears out, but another. Old school royalex was heavy, I have a 16 footer at school that is 70 pounds.

Similar threads

- Replies

- 10

- Views

- 496

- Replies

- 73

- Views

- 6K

- Replies

- 75

- Views

- 3K

- Replies

- 42

- Views

- 4K