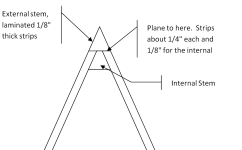

The inner and outer stems are steamed together at the same time, so it's a matter of fit. Plus, the two stems are completely laminated together, and I have lots of purchase for when I attach the brass stem band. In the latest build, you can see the outer stem planed down flush to the hull and the flaring out to cap the strips.

I'm not sure I can envision what you are describing wysedav. Do you have a pic?

I'm not sure I can envision what you are describing wysedav. Do you have a pic?