Finally did the rough sanding of the inside, it takes a lot of mental fortitude to do the inside. Hopefully give it the final sanding tonight and glass sometime this week. Crack filled too.

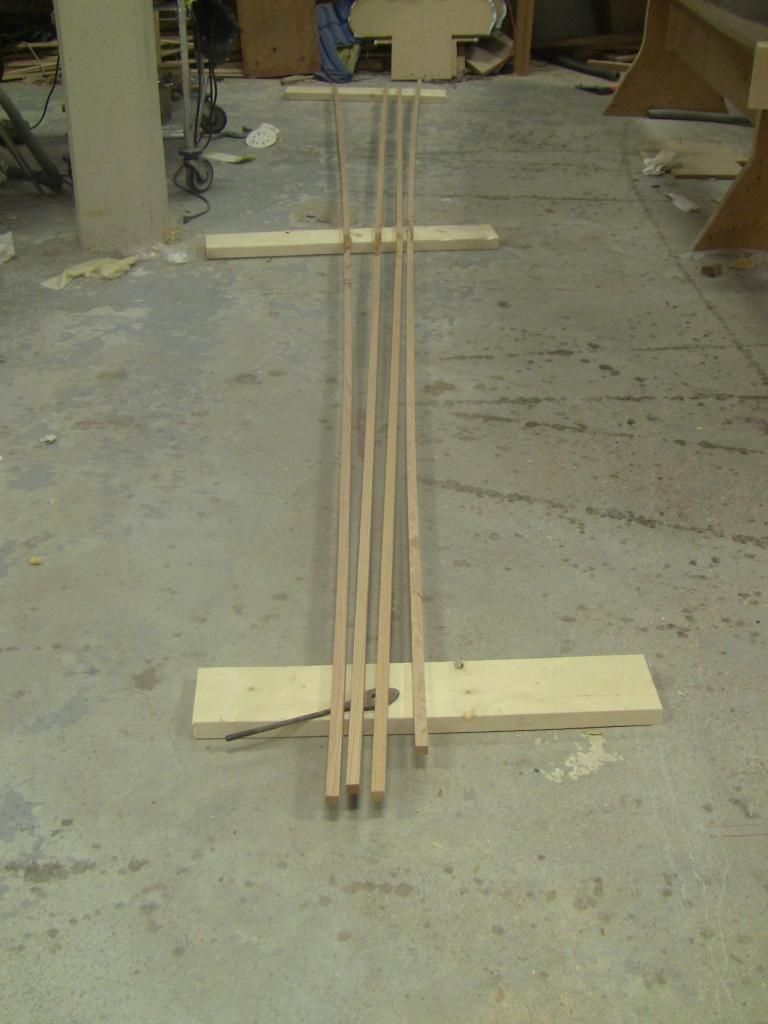

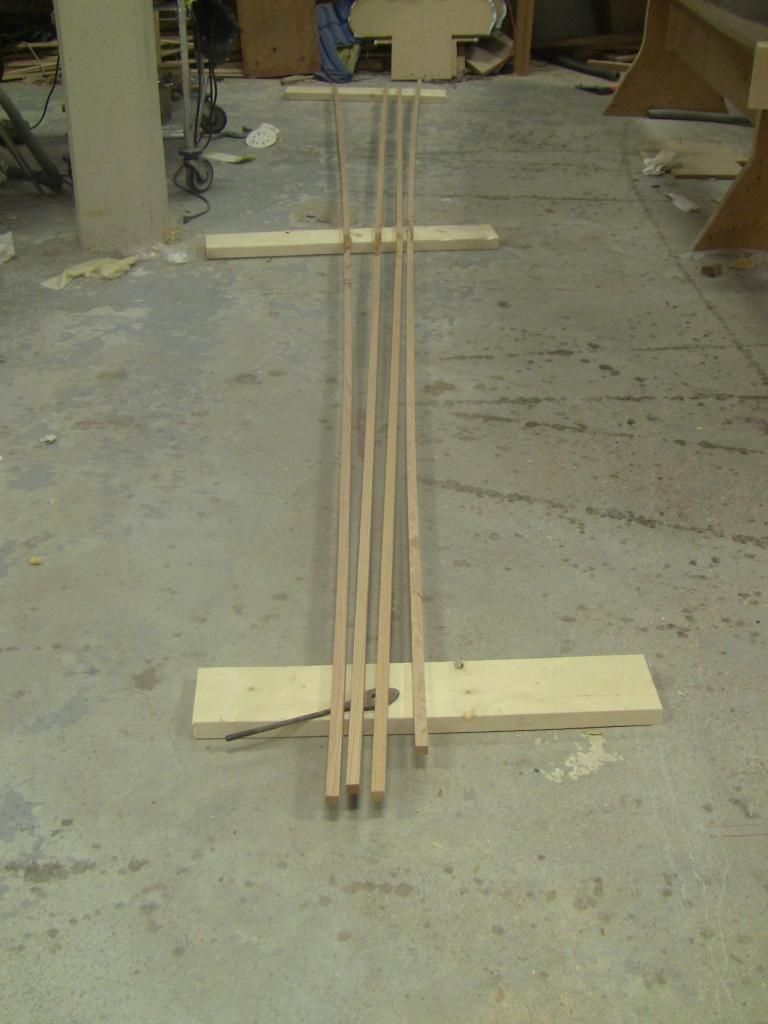

Glued up the gunwales last week, decided to go with some oak I had, as the birch would have required several scarf joints.

Once the fiberglassing is done, I'll be bringing it home to my garage, then things will go quickly, I'll be able to work on it for a bit every day. Think I'll paint the inside red again.

Glued up the gunwales last week, decided to go with some oak I had, as the birch would have required several scarf joints.

Once the fiberglassing is done, I'll be bringing it home to my garage, then things will go quickly, I'll be able to work on it for a bit every day. Think I'll paint the inside red again.