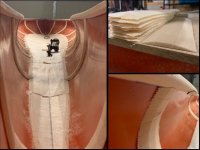

I still have to polish the mold, but I thought I'd get started on the gunwales. It's a milestone because it is the first time I am working on something that will be part of the final boat. The gunwale profile I successfully tested is an "L" shape that sits on the top edge of the mold. I milled them from a sheet of 3/8" PVC foam (5lb divinycell). First, I cut 1" strips (horizontal component) on the band saw, then ran them through the router to round off three of the edges. The vertical component was made by cutting a 3/4" strip, then cutting one end at a 45degree chamfer to blend flush to the hull. This would be easy to assemble if the canoe edge was 90degrees along it's length- but in fact the hull meets the top flange at a an angle that varies along the length of the hull. So I taped the vertical piece along the hull, and cut the top flush with the top flange. Then I glued on the top component- using a heat gun to bend the strips as required. Sewing pins held it together while the glue dried. So each gunwale now follows the exact curve of the hull and sits nicely on the edge without having to clamp or hold it or anything.

As the boat will have a rudder, I used a Dremel to mill out a channel in the gunwales to run control cable tubing. This means I also had to estimate where the seat and foot pegs will be located. As far as I know, the front edge of the seat in solo boats is usually just at or just behind the balance point of the canoe. I went back to the CAD file, found the center of mass of the 3.5" waterline (center of buoyancy) and choose that as the location for the front edge of the seat. The seat will be a pedestal slider with around 16" of travel, so I have some room for error. Then I located the center of the sliding foot pegs 32" in front of the seat. The rudder I choose is the Select Designs Truecourse with gas-pedal type foot controls. The only thing I don't like about it is the weight of the components is heaver than I would have thought. I will likely make replacement parts for it out of carbon fiber in the future, but for now the stock components will do. It seems like a good design.

Then I cut some of the sheets for the foam core. These are 1/4" PVC foam (5lb divynicell) that are scored in 40mm squares and attached to a scrim backing cloth. They conform to the curved hull surface, and act as an internal flow media to help the infusion. I tested the scored vs drilled foam, and found that the scored foam infuses better with the rest of my layup, but retains more resin (weight) after infusion. Attempting to calculate the difference, I estimate the total boat weight scored foam will be 9oz heavier than a boat with drilled foam. In my mind that's an acceptable trade-off for a better infusion. I am an amateur after all, and want to make this go as smoothly as possible the first time.

I still have to cut out the ribs. I'm not sure how many I need. My 16" test panel had two and was incredibly stiff, so I think I could get away with less, if not any at all. Looking at manufacturer websites for info, the number of ribs varies for ultralight canoes of comparable length: Swift uses 5, Wenonah uses 8, Savage River uses 11, and Mad river uses 5. I'm sure it depends on the layup schedule (which isn't always published). The sides of my Northstar18 (vinylester) is two layers of kevlar and it only has 4 ribs along its length (but each is about 10" wide). I'd appreciate if anyone has insight into this, but I think it is more of a question for finite element analysis software. Almost every part of the hull surface is curved in two compound directions, so there should be a lot of inherent stiffness, and I bet I could get away with no ribs at all. I'll probably do somewhere between 6 and 8 ribs each side.

As the boat will have a rudder, I used a Dremel to mill out a channel in the gunwales to run control cable tubing. This means I also had to estimate where the seat and foot pegs will be located. As far as I know, the front edge of the seat in solo boats is usually just at or just behind the balance point of the canoe. I went back to the CAD file, found the center of mass of the 3.5" waterline (center of buoyancy) and choose that as the location for the front edge of the seat. The seat will be a pedestal slider with around 16" of travel, so I have some room for error. Then I located the center of the sliding foot pegs 32" in front of the seat. The rudder I choose is the Select Designs Truecourse with gas-pedal type foot controls. The only thing I don't like about it is the weight of the components is heaver than I would have thought. I will likely make replacement parts for it out of carbon fiber in the future, but for now the stock components will do. It seems like a good design.

Then I cut some of the sheets for the foam core. These are 1/4" PVC foam (5lb divynicell) that are scored in 40mm squares and attached to a scrim backing cloth. They conform to the curved hull surface, and act as an internal flow media to help the infusion. I tested the scored vs drilled foam, and found that the scored foam infuses better with the rest of my layup, but retains more resin (weight) after infusion. Attempting to calculate the difference, I estimate the total boat weight scored foam will be 9oz heavier than a boat with drilled foam. In my mind that's an acceptable trade-off for a better infusion. I am an amateur after all, and want to make this go as smoothly as possible the first time.

I still have to cut out the ribs. I'm not sure how many I need. My 16" test panel had two and was incredibly stiff, so I think I could get away with less, if not any at all. Looking at manufacturer websites for info, the number of ribs varies for ultralight canoes of comparable length: Swift uses 5, Wenonah uses 8, Savage River uses 11, and Mad river uses 5. I'm sure it depends on the layup schedule (which isn't always published). The sides of my Northstar18 (vinylester) is two layers of kevlar and it only has 4 ribs along its length (but each is about 10" wide). I'd appreciate if anyone has insight into this, but I think it is more of a question for finite element analysis software. Almost every part of the hull surface is curved in two compound directions, so there should be a lot of inherent stiffness, and I bet I could get away with no ribs at all. I'll probably do somewhere between 6 and 8 ribs each side.