You are right, I sit corrected.

-

Happy Boxing Day! 🎁📦💰

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's happening in your shop this winter?

- Thread starter Alan Gage

- Start date

36" wide, 13.5 deep, 17" deep at the front deck, 18 at the rear.

Next!!! 3rd of 4.

16 foot Langford that Christine picked up late Summer and came without seats or thwarts. Needs a bit of work. It has 56 full ribs and the 4 cant ribs. It needs 62 rib tips and all 4 cant ribs, stems are broken, one end down a fair ways, the other further up, inwale tips and maybe deck tips. Then of course, seats and thwarts, varnish and canvas. Thankfully all the ribs are good. We are still leaving the worst for last of the 4 boats in the queue.

She said she wasn't buying any more boats until we have the Penobscot and the Morris done as well, but anyone want to bet she can hold off a couple of years?

16 foot Langford that Christine picked up late Summer and came without seats or thwarts. Needs a bit of work. It has 56 full ribs and the 4 cant ribs. It needs 62 rib tips and all 4 cant ribs, stems are broken, one end down a fair ways, the other further up, inwale tips and maybe deck tips. Then of course, seats and thwarts, varnish and canvas. Thankfully all the ribs are good. We are still leaving the worst for last of the 4 boats in the queue.

She said she wasn't buying any more boats until we have the Penobscot and the Morris done as well, but anyone want to bet she can hold off a couple of years?

I need to stop buying boats. Good luck with that also.

Nice claw marks in the stern.

Nice claw marks in the stern.

Well, I still working on the Rob Roy. I got one set of bent and oiled gunwales back on after laying down a layer of resin to fill all the holes on the cowling lip. I was worried about the memory of the wood but it all fit back in without much of a struggle. Now it's time to take the other set of gunwales off and bring them up to the house, warmth, for an oiling session, resin the other sided of the cowling and then reinstall the gunwales. I have faith the memory of those will not give me a problem either. From there I need to build a new deck plate and come spring some skid plates to hide the nasty ones that are there. Still on the fence as whether a paint job is need on the underside.

dougd

dougd

Many post back on this thread I expressed hope of buying a lovely canoe from a friend of my. He believed it to be a Rushton Indian Girl but hanging rightside up it was really hard to tell. He wanted $1000 and I could tell the inwales were broken and the ribs were pulling away in other areas and according to some bulging planking it was clear there were some broken frames. Hanging as it was and seeing what I could see with no way to confirm an Indian Girl there was no way I was going to pay that kind of money. He is a friend of mine and he is 86 (very active and fully plans to paddle this summer) so we continued to banter back and forth about a sale. Finally he decided it was too dear to him as his father bought it in the '60's, so no sale he was going to do the repairs himself. So I told him when he want to start I'd help him as I could and if I could have a day to measure it. Even hanging in the rafters I knew it was lovely. So that is what I did yesterday.

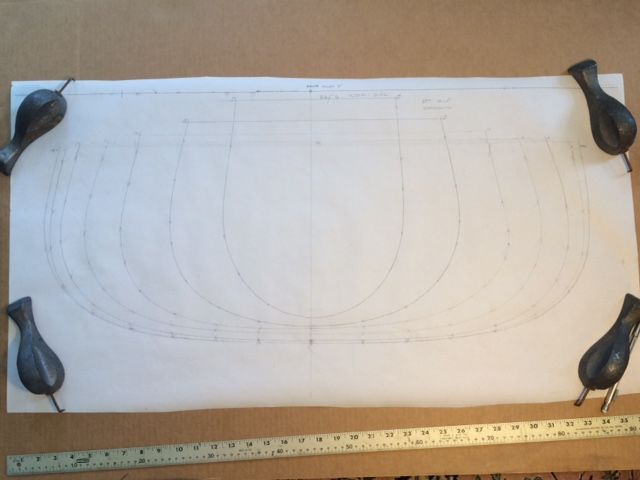

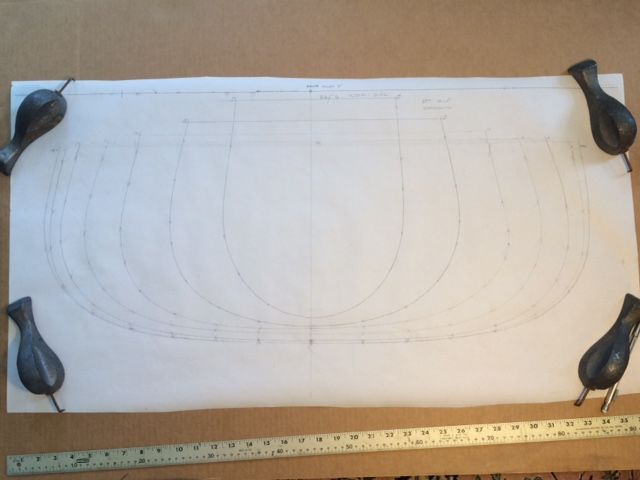

So far it looks really fair. This is just the aft half, I still have to transcribe to bow half. Eventually it will be turned into a set of plans.

As it turns out it really is an Indian Girl Canoe.

Jim

So far it looks really fair. This is just the aft half, I still have to transcribe to bow half. Eventually it will be turned into a set of plans.

As it turns out it really is an Indian Girl Canoe.

Jim

Neat and simple way of pulling lines of an existing canoe. I assume the compass stays at a known, and fixed, width so that when you transfer lines from the cardboard onto paper you know to add 3", for example?

Alan

Alan

Yes that is correct. In fact before I swing any arcs I slide the dividers under the wooden cross arm to draw a line so each pattern has a reference of the spacing, just in case it gets bumped. So the pencil scribes onto the cardboard then to transcribe, the curved arm is replaced with a straight point and set at the proper spacing. The point in placed anywhere on the drawn arc and the pencil scribes an arc on the paper, shift to another point on the arc and scribe again to reproduce the original pivot point.

Jim

Jim

- Joined

- Mar 20, 2013

- Messages

- 3,356

- Reaction score

- 972

That is really cool... I don't think I'm smart enough to understand the process, but it is cool!!

It's funny how many different ways there are to taking lines from a hull !

This is interesting, to say the least. The real test, is when done, you can cut up a COPY of your lines, and see if they match up to the original !

Years ago I took lines from a Jensen 17. It involved a round piece of wood, (a 2"hole saw cut out), a piece of card board, and a pencil, inserted in the middle of the wood cut out. Two people made it a lot easier.

Someday I'll try and describe it in more detail, with pics..

Jim

This is interesting, to say the least. The real test, is when done, you can cut up a COPY of your lines, and see if they match up to the original !

Years ago I took lines from a Jensen 17. It involved a round piece of wood, (a 2"hole saw cut out), a piece of card board, and a pencil, inserted in the middle of the wood cut out. Two people made it a lot easier.

Someday I'll try and describe it in more detail, with pics..

Jim

I know just what you are describing Jim. In fact Lee Valley sell a set of discs just for that purpose. One advantage of this system is the point on the hull that I used to swing the initial arcs were the joints in the planking, so all in motion I captured the shape of the hull and the plank layout. I think you can see the little 'X's where I worked the arcs backwards. In another of those photos is another tool I use for taking shapes (or spiling) that little zig zag tool. Put the point on the planking and trace around it, then to reconstruct just lay the tool inside the tracing and mark the point. I was working alone this time so the dividers made more sense.

Since I have access to the boat, I'll cut out some cardboard and check a couple stations. Still a lot to do before then, from these full size drawings I create a table of offsets, from those offsets I draw the boat out 1/2 scale to fair everything with the long lines, then take it back to the body plan and create an amended set of offsets. From there I'm ready to build or create a set of plans. I've measured about 8 boats so far (starting back in the '80's) and sell plans for four of them.

Jim

Here is the link to LV and you can see the process.

http://www.leevalley.com/us/wood/page.aspx?p=50272&cat=1,42936,50298

Since I have access to the boat, I'll cut out some cardboard and check a couple stations. Still a lot to do before then, from these full size drawings I create a table of offsets, from those offsets I draw the boat out 1/2 scale to fair everything with the long lines, then take it back to the body plan and create an amended set of offsets. From there I'm ready to build or create a set of plans. I've measured about 8 boats so far (starting back in the '80's) and sell plans for four of them.

Jim

Here is the link to LV and you can see the process.

http://www.leevalley.com/us/wood/page.aspx?p=50272&cat=1,42936,50298

Last edited:

I know just what you are describing Jim. In fact Lee Valley sell a set of discs just for that purpose.

Here is the link to LV and you can see the process.

http://www.leevalley.com/us/wood/pag...=1,42936,50298

Yes, that is the same principle, I just used a plywood disc, about 3/4" thick, from a hole saw cut out. It held a #2 pencil. Huh !

You are working from the inside of the hull, and I worked from the outside. The Jensen had a flat keel line that made it easier also.

Your plans look very good !

Jim

Last edited:

Check with a local Craft Brewery, they age some of their beers in them.

Nice work, looks sharp next to that dark wood.

I thought winter was over but the foot of snow yesterday says otherwise so I guess the thread is still alive for me. But spring is coming and I'm rushing to finish some boats:

20170313_013 by Alan, on Flickr

20170313_013 by Alan, on Flickr

The little stripper is the Nature Center donation that will be raffled next weekend. It's been getting hauled around all summer and winter and picked up some scratches so I wanted to give it another coat of varnish. Gonna be nip and tuck. Didn't get it back until Saturday and didn't realize I was almost out of varnish until the stores closed. Used up the dregs of a can and figured out why they always recommend decanting into another container. It had debris from about 6 different projects floating around in the can and the finish came out a little "fuzzy". Hoping in the next day or two it will be hard enough to sand. Fingers crossed I can just wet sand with 1500 grit and get a decent finish. Then I still need to do the trim. I'd like to varnish it for looks but might run out of time and just give it another coat of oil.

The next boat in line is my large volume solo. Just waiting for some epoxy to fully cure before painting the inside. Then all it will need is thwarts and it will be ready to hit the water.

The third boat in line is the composite tandem I've been working on, or maybe I should say not working on, for over a year now. She's close. Just need to finish up seats.

The last boat is my Bloodvein. It's in the shop to get cleaned up after last year's trip. The bottom has been re-varnished and it could go out in the canoe shed if there was room for it.

I had grand plans to finally finish the trim in my house (window sills, baseboard, and doors) but that might have to wait a little longer. Got a few window sills done and more lumber is in the shop getting acclimated but it still needs to be planed down, a straight edge ripped, stained and varnished.

Alan

20170313_013 by Alan, on Flickr

20170313_013 by Alan, on FlickrThe little stripper is the Nature Center donation that will be raffled next weekend. It's been getting hauled around all summer and winter and picked up some scratches so I wanted to give it another coat of varnish. Gonna be nip and tuck. Didn't get it back until Saturday and didn't realize I was almost out of varnish until the stores closed. Used up the dregs of a can and figured out why they always recommend decanting into another container. It had debris from about 6 different projects floating around in the can and the finish came out a little "fuzzy". Hoping in the next day or two it will be hard enough to sand. Fingers crossed I can just wet sand with 1500 grit and get a decent finish. Then I still need to do the trim. I'd like to varnish it for looks but might run out of time and just give it another coat of oil.

The next boat in line is my large volume solo. Just waiting for some epoxy to fully cure before painting the inside. Then all it will need is thwarts and it will be ready to hit the water.

The third boat in line is the composite tandem I've been working on, or maybe I should say not working on, for over a year now. She's close. Just need to finish up seats.

The last boat is my Bloodvein. It's in the shop to get cleaned up after last year's trip. The bottom has been re-varnished and it could go out in the canoe shed if there was room for it.

I had grand plans to finally finish the trim in my house (window sills, baseboard, and doors) but that might have to wait a little longer. Got a few window sills done and more lumber is in the shop getting acclimated but it still needs to be planed down, a straight edge ripped, stained and varnished.

Alan

Similar threads

- Replies

- 161

- Views

- 12K

- Replies

- 13

- Views

- 2K

- Replies

- 14

- Views

- 944

- Replies

- 11

- Views

- 1K