Copied from a thread called The Canoe found on the bwca.com site. It all came about from a renovation, a road trip and a slight suggestion from my father. A little long but it is provided on request.

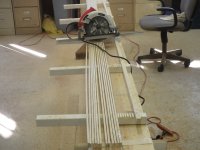

This project has been a while in concept and implementation, as I have considered building my own canoe for over a year. To set the stage, please follow a previous post and I will pick up the construction thread as I progress with my build.

Disclaimer: This will be my first woodcraft project since making a guillotine frame in Mr. Melcher's 9th grade wood shop class. The next quarter I cast an aluminum blade in metals shop. Cool but very crude. My strongback and form, a Merlin, are on loan from renowned master knife forger Karl Andersen and I have had virtual support from Jim D, a vigorous contributor and fine composer of water craft. A special nod of approval goes to everyone who has posted upon the bwca.com site and perhaps more importantly, the builders group section. Your canoe construction stories have inspired me and it is my hope to build a vessel capable of withstanding your scrutiny. Kudos to my Dad as well as he inspired my building The Canoe.

This will not be a fast build as my shop address in near my father's house, 20 miles away and my time is like yours, split between work and play.

The finished product will be a working canoe for my solo trips to the BWCA and beyond. I look forward to wearing The Canoe out.

The past:

9/02/14 bwca.com post

12 hours 11 minutes, 623 miles, 7 pit stops, numerous small towns, rain, sunshine, lunch in Independence, a bag of fresh home baked chex-mix and many recollections made Labor Day 2014 perhaps the most memorable, and enjoyable, holiday I have had in a long time. All because of a chance of an old canoe.

On the south side of St. Paul, my father mentioned to me that he likely hadn't been twenty miles from home in over four years. We traveled through his sales territory on our way to central Iowa; each sight a new story, each story another insight into my Dad. Our first stop in Zumbrota was a wake up for me as the "walker" had replaced the "cane" and taking a restroom break underscored the aging process as a challenge each of us will face in our own way at some time. My father, the one who introduced me to the BWCA in the mid-1960's, whose first canoe was a 1955 red Old Town wood/canvas and whom I have admired for his tenacity and intelligence is maturing gracefully...although way too fast. Our excitement over the canoe project was building as we continued down 52 in and out of both vibrant and gentrified farm communities.

Lunch was to have been in "one of those family diners", and although we looked for one high and low, our tastebuds settled upon BBQ at an all around sports club/family dining/bar and grill called Bill's. We left with a doggie bag and more than half of his order. No appetite anymore from a guy who hovered around 180 the last 60 years and loved good food. One hour to go and we would be viewing the catalyst of the day's adventure. By now the "what if" game was being kicked around. What if it has dry rot, what if it is too long for transport back on top of my Impreza, what if it is in amazing shape, what if the small amount of gunnel rot the owner mentioned on the phone is just an easy fix, what if it we moved the table saw to create more space in the shop, what if we painted it red just like your first canoe....

Jerry, a fine gentleman greeted us at his house and we followed him to his storage facility for the viewing. At first blush my heart stuttered upon realization that this restoration opportunity was way, way more than I had anticipated. Although pretty handy with tools and quite able to ferret out answers to wood craft mysteries, the extent of my patience was not going to do the vessel any favors. It was apparent quite quickly that the restoration of this canoe would likely test our father/son relationship rather than enhance it.

Many cracked ribs, missing half-ribs, rotted stems, disintegrating gunnels, animal chewing damage upon numerous ribs and bow planking worn through on the transport trailer quickly brought my father and me back to reality. We wanted a project that we could complete together in his remaining life-time and not one that would over-tax our future days. This canoe deserved better than us to make her dance upon the water again. This canoe would require an experienced restoration craftsman with the tools necessary for a bottom up rebuild.

You bet we may have left a valuable example of canoe heritage in that Iowa pole barn, but to be honest, it sure was nice not to put it on the top of my car. In all likelihood we would have been scattering loose planks, delaminated gunnels and busted ribs across Iowa as we transported the 18 foot piece of kindling back home.

However this canoe was a vehicle of great satisfaction as it brought a father and son much closer together. I reheard many of his tales of triumph and tragedies, politics and motivations as we cruised our way to and from Montecello. Every new small town a story, every mile on the road a memory, I could not have had a better adventure.”

As I recall, somewhere around Northfield and a side trip down memory lane to Dad’s college years at Carlton, he turned to me and said, “Rather than wait for a fixer upper, why not build your own canoe?”

photo3531.jpg459.2 KB · Views: 2

photo3531.jpg459.2 KB · Views: 2 photo3532.JPG164.4 KB · Views: 2

photo3532.JPG164.4 KB · Views: 2 photo3533.jpg231.8 KB · Views: 0

photo3533.jpg231.8 KB · Views: 0 photo3534.jpg388.2 KB · Views: 2

photo3534.jpg388.2 KB · Views: 2 photo3535.jpg138.8 KB · Views: 2

photo3535.jpg138.8 KB · Views: 2 photo3536.jpg114.7 KB · Views: 2

photo3536.jpg114.7 KB · Views: 2 photo3537.jpg465.5 KB · Views: 2

photo3537.jpg465.5 KB · Views: 2 photo3538.jpg379.2 KB · Views: 2

photo3538.jpg379.2 KB · Views: 2 photo3539.jpg313.8 KB · Views: 2

photo3539.jpg313.8 KB · Views: 2 photo3540.jpg498.7 KB · Views: 2

photo3540.jpg498.7 KB · Views: 2 photo3541.jpg315.8 KB · Views: 2

photo3541.jpg315.8 KB · Views: 2