Frank,

For a first build, i would definitely second Jim in getting a copy of CanoeCraft ... that book was my lifeline for the first build. I read it cover to cover 3 times before I started my first build, I keep it in the shop.

Brian

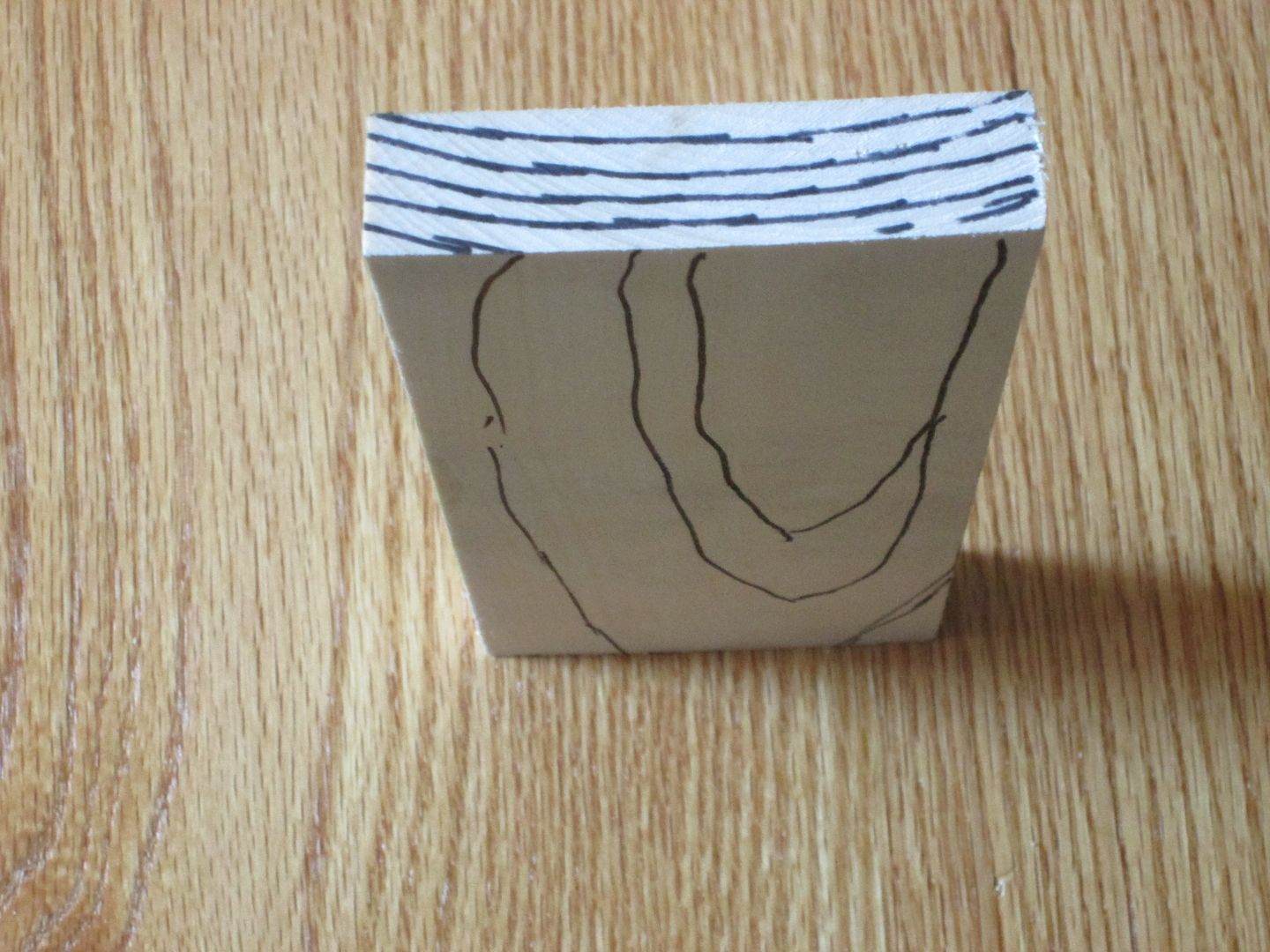

Brian, my CanoeCraft copy, as well of the plans for the Freedom 17, are here. After all your kind advises, I have a better picture and it is time to plan and do:

1) Calculate the $$ for the spanish cedar (might do the purchase in two halfs)

2) Clean the room for space

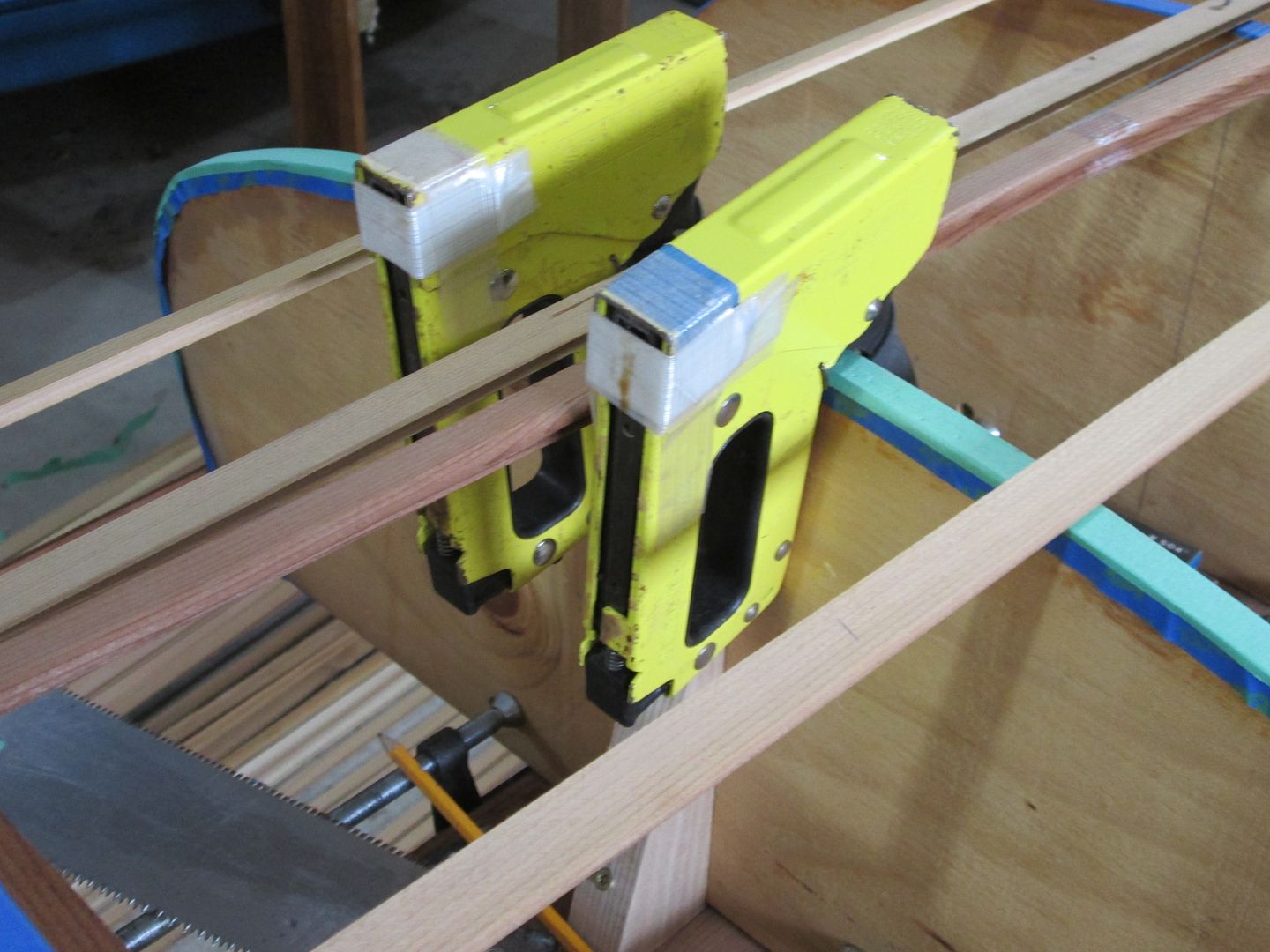

3) Built the strong back

4) Prepare the cedar

5) Built a steamer to bend wood for stems

6) and everything that happens from here

All of you guys are very kind, thanks a lot