Finally, the prep work for the build is done and I can tackle the forms, first step ... dig my original forms out of the shed, then figure out the modifcation of the stern and bow stems.

This is the original bow stem assembly, with St 1 and St 2 attached:

I drew up the new stems in the summer, I traced the old form on a piece of graph paper setup for lofting, this gave a point of reference when making alterations ... I tried a couple of different radius types and stayed with the one that has the sheer notch. There is also a ref line for where the tumblehome falls, that is kept to help align the initial strips to help with the accent strip placement.

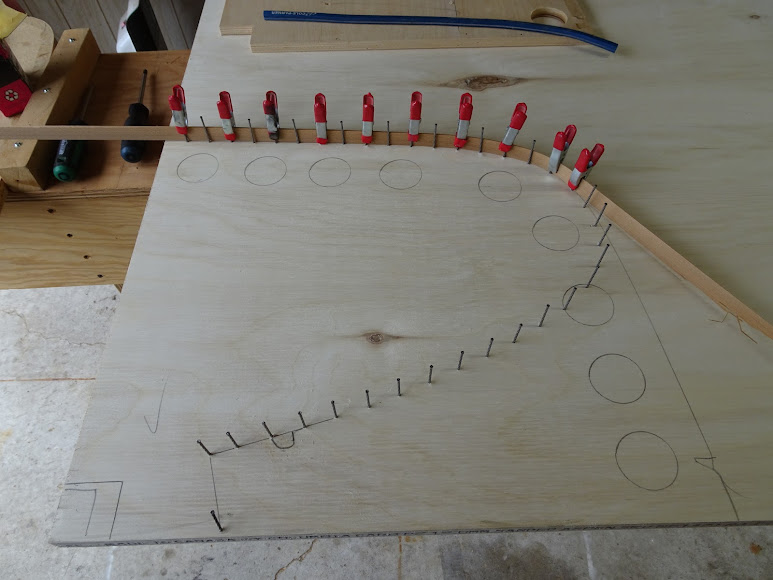

To transfer the shape, the drawing is positioned and taped in place, then finishing nails are placed every inch or so. The drawing looks a little strange, but the explanation is that I wanted to use the ply left edge as it was the manufactured edge, and I had to flip the bow drawing over, it was still visible enough to do the transfer.

Carefully lift the paper away and you are left with just the nails, use some clamps and a fairing strip, draw between the nails with a pen or pencil. I started with a marker, not a good idea, bleeds too much. You can also see the original shape ... that was transferred for reference.

Cut out and sand to the line, reposition clamp holes as required and presto ... a new form is born.

It was pretty clear that the last (or first) stations would require modifications, so I duplicated the existing St1/St2 and St14/St15, as I wanted to keep the original form set intact for possible future builds.

The new St15/St1 (wings on the stem form) were largely eyeballed using a fairing stick and common sense as to how the strips had to fall. The stem form (stern pictured) was assembled and the St13 modification was determined and marked on the form (you can see the new shape marked in pencil.

Once the bow/stern stem assemblies where completed, it became clear that I would need to also modify the next station as well to space out the twist the new shape required. It was a small change, near the sheer, just to ease the twist over a longer length. Here is the completed set ready to be installed:

So the new shape required changing the stem form and 3 stations at each end ... I won't know how well the changes work until I start stripping.

Brian

This is the original bow stem assembly, with St 1 and St 2 attached:

I drew up the new stems in the summer, I traced the old form on a piece of graph paper setup for lofting, this gave a point of reference when making alterations ... I tried a couple of different radius types and stayed with the one that has the sheer notch. There is also a ref line for where the tumblehome falls, that is kept to help align the initial strips to help with the accent strip placement.

To transfer the shape, the drawing is positioned and taped in place, then finishing nails are placed every inch or so. The drawing looks a little strange, but the explanation is that I wanted to use the ply left edge as it was the manufactured edge, and I had to flip the bow drawing over, it was still visible enough to do the transfer.

Carefully lift the paper away and you are left with just the nails, use some clamps and a fairing strip, draw between the nails with a pen or pencil. I started with a marker, not a good idea, bleeds too much. You can also see the original shape ... that was transferred for reference.

Cut out and sand to the line, reposition clamp holes as required and presto ... a new form is born.

It was pretty clear that the last (or first) stations would require modifications, so I duplicated the existing St1/St2 and St14/St15, as I wanted to keep the original form set intact for possible future builds.

The new St15/St1 (wings on the stem form) were largely eyeballed using a fairing stick and common sense as to how the strips had to fall. The stem form (stern pictured) was assembled and the St13 modification was determined and marked on the form (you can see the new shape marked in pencil.

Once the bow/stern stem assemblies where completed, it became clear that I would need to also modify the next station as well to space out the twist the new shape required. It was a small change, near the sheer, just to ease the twist over a longer length. Here is the completed set ready to be installed:

So the new shape required changing the stem form and 3 stations at each end ... I won't know how well the changes work until I start stripping.

Brian