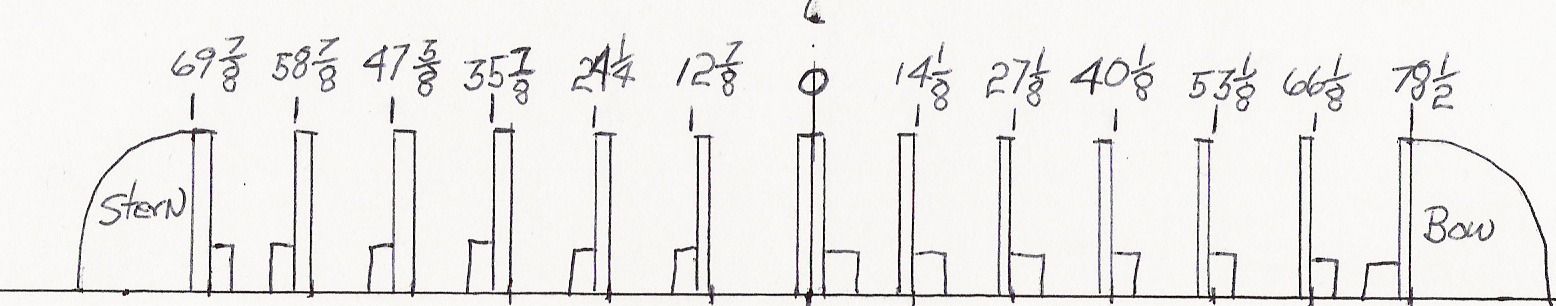

Hi everyone - I've recently begun work building - you guessed it - a Kite. The strongback is assembled, stations are in place and aligned, strips are cut, beaded, and coved, and stems attached (but not yet shaped).

I have a question regarding fairing the mold. That is, beveling the sides of the stations so that strips lay flat against them. I've only seen a couple of brief, mostly uninformative references to this in print. I can't seem to find any mention of the practice in this forum, nor have I seen any YouTube videos demonstrating it. What I've read stresses the importance of doing this to avoid distortions in the hull at sharp station edges that have not been faired. I'm using 3/16" strips and plan to paint the exterior, so naturally this warning caught my attention. What's your thinking on this?

Thanks!

I have a question regarding fairing the mold. That is, beveling the sides of the stations so that strips lay flat against them. I've only seen a couple of brief, mostly uninformative references to this in print. I can't seem to find any mention of the practice in this forum, nor have I seen any YouTube videos demonstrating it. What I've read stresses the importance of doing this to avoid distortions in the hull at sharp station edges that have not been faired. I'm using 3/16" strips and plan to paint the exterior, so naturally this warning caught my attention. What's your thinking on this?

Thanks!