I've been wondering, that when you pull the blue peel ply off the hull, did it soak up any of the resin ? And by chance would it be reusable ?

Jim

It will have soaked up some of the resin and won't be reusable. It's just little scraps though.

Alan

I've been wondering, that when you pull the blue peel ply off the hull, did it soak up any of the resin ? And by chance would it be reusable ?

Jim

20151217_001 by Alan, on Flickr

20151217_001 by Alan, on Flickr 20151217_002 by Alan, on Flickr

20151217_002 by Alan, on Flickr 20151217_003 by Alan, on Flickr

20151217_003 by Alan, on Flickr 20151219_001 by Alan, on Flickr

20151219_001 by Alan, on FlickrWow ! I wouldn't have expected the hulls to stick either.

Glad Muskrat spoke up earlier !

Could you tell where they bonded together ? Or was it just wedged together ?

Jim

Would carbon fiber given you more stiffness than the Kevlar ?

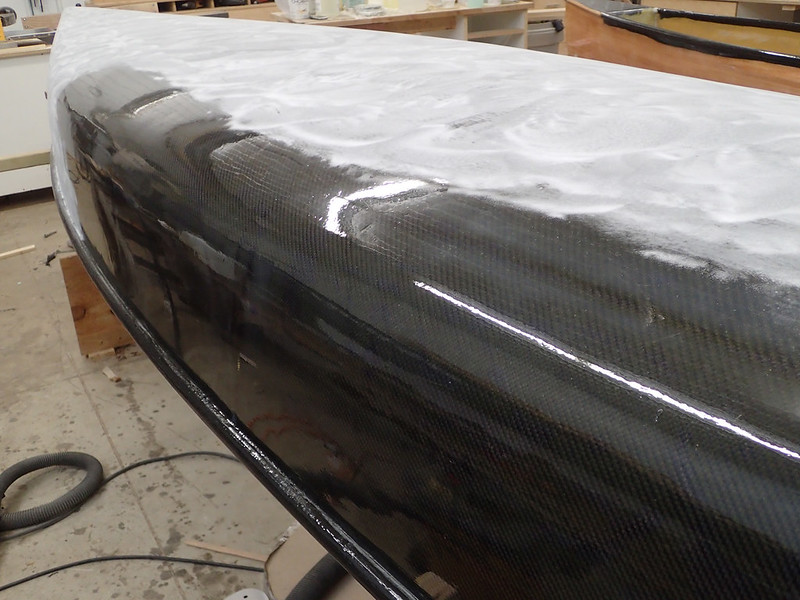

20161202_001 by Alan, on Flickr

20161202_001 by Alan, on Flickr 20161202_002 by Alan, on Flickr

20161202_002 by Alan, on Flickr 20161202_003 by Alan, on Flickr

20161202_003 by Alan, on Flickr 20161202_004 by Alan, on Flickr

20161202_004 by Alan, on FlickrIam learning alot- thanks, I know its your design, looking like SRT 15', bow 21, c 14, s 18,

width 28.5, rail 26

what are your specs

Jim asked:

What are you going to use for seats ?

Brad creeped us all out with: She tickled my fancy from the get go on page 1. By page 2 I fell in love. Then came page 3 and I fell hard, real hard in love with that carb/kev canoe of yours.

And then I forgot all about her. Absence might make the heart grow fonder, but this forgetful old fool is fickle. Out of sight out of mind and all that.

And now she's back, looking exotic and...Alan, you sure like messin with canoe builds and messin with my heart. Keep up the good work. Now I need a cold shower.

20170121_002 by Alan, on Flickr

20170121_002 by Alan, on Flickr 20170305_002 by Alan, on Flickr

20170305_002 by Alan, on Flickr 20170305_003 by Alan, on Flickr

20170305_003 by Alan, on Flickr