I finally pulled the trigger on buying the supplies needed for my future build composite canoe, so I guess I HAVE to turn them into something I can paddle  This might be last one I get to build due to space constriction (and my wifes patience) so I am going for the gusto! The goal is to make the strongest, lightest tripping canoe as cost effectively as possible. I never would have had the inspiration or guts to try this without all the awesome folks on this forum! I might be in way over my head but here is to adventure!

This might be last one I get to build due to space constriction (and my wifes patience) so I am going for the gusto! The goal is to make the strongest, lightest tripping canoe as cost effectively as possible. I never would have had the inspiration or guts to try this without all the awesome folks on this forum! I might be in way over my head but here is to adventure!

The layup from inside to out

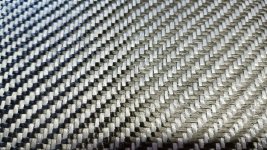

- 5.7 oz Carbon-innegra twill weave

- 6 oz Intermediate Modulus Carbon Fiber satin weave

- 3.16 oz Style 120 E Glass

- 4 oz S glass football

I am also going to try for those cool composite gunwales I have seen Alan, Stripperguy, and others do. However, I am going for cost effective so I hope that pink polystrene is strong enough with 15 oz CF tape. I will be doing ribs with 5.7 IM CF and the same foam. I know the expert conventional wisdom is a foam core, but that adds weight, cost, and most importantly plenty of ways I could muck it up.

I made up a mock panel that I will post later but here are the things I wanted to test

- Stiffness compared to Moran style Kevlar layup

- Flex compared to Kevlar

- What happens when it breaks in half?

- Cutting Carbon Innegra fabric

- Wet out of Carbon Innegra

- Secondary bonding on Carbon Innegra fabric

- Foam rib strength

- Laying up carbon on ribs

- Laying up Style 120 E Glass

- Using peel ply. My first time using it.

Here is a picture of the materials. The Innegra is actually black so this will be a dark as night canoe.

Any feedback, suggestions, or questions are welcome!

The layup from inside to out

- 5.7 oz Carbon-innegra twill weave

- 6 oz Intermediate Modulus Carbon Fiber satin weave

- 3.16 oz Style 120 E Glass

- 4 oz S glass football

I am also going to try for those cool composite gunwales I have seen Alan, Stripperguy, and others do. However, I am going for cost effective so I hope that pink polystrene is strong enough with 15 oz CF tape. I will be doing ribs with 5.7 IM CF and the same foam. I know the expert conventional wisdom is a foam core, but that adds weight, cost, and most importantly plenty of ways I could muck it up.

I made up a mock panel that I will post later but here are the things I wanted to test

- Stiffness compared to Moran style Kevlar layup

- Flex compared to Kevlar

- What happens when it breaks in half?

- Cutting Carbon Innegra fabric

- Wet out of Carbon Innegra

- Secondary bonding on Carbon Innegra fabric

- Foam rib strength

- Laying up carbon on ribs

- Laying up Style 120 E Glass

- Using peel ply. My first time using it.

Here is a picture of the materials. The Innegra is actually black so this will be a dark as night canoe.

Any feedback, suggestions, or questions are welcome!

Attachments

Last edited: