What is this reluctance to poke holes in hulls and then plug them?

I can understand the compunction. For some, it might be as simple as resale value, but I think there's a corollary amongst automotive enthusiasts: some are willing to modify body panels on a classic car for customization, whereas others think it's sacrilege to "chop" a classic. I fall in the middle. I've drilled boats but would also be glad to find a more elegant solution, as long as I'm not compromising utility/durability.

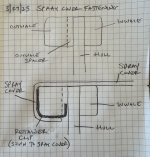

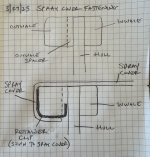

Towards this end, I've been noodling on an idea for a spacered-outwale that would allow retainer clips to be sewn into the outer edge of the spray cover. The retainer clips would slot into the bottom of the outwale spacers from below, so that the spray cover wraps the outwale completely, but otherwise doesn't need to attach to the hull at all.

Please forgive the crude nature of this hasty sketch. It shows a spacered-outwale in cross section and then a second cross section detailing how the clip and spray cover might engage the outwale:

An alternative version might be a retainer clip that is continuously engaged into a rabbet in the bottom of the outwale, akin to the retainer flange at the bottom edge of a Jeep Wrangler soft top. That version might eliminate any sag in the spray cover fabric between the outwale clips.

The "rabbet" on the body of a jeep, looks like this:

I could imagine that rabbet becoming a standard feature of production gunwales. One obvious downside is that during storage any overturned boat would be likely to accumulate crud in the rabbet.