G

Guest

Guest

Hulls with shallow or deep V contours are prone to wear down the keel line.

Pete, I’ve seen your boat repair and outfitting work for some years now. Seriously well done boatwork, and I’ve learned a bunch. I’m still learning and hope you will photo document the Mohawk XL 13 and share it here.

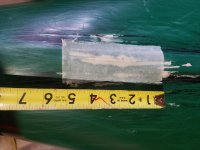

I’ve laid full length keel strips on a couple or four Mad River or composite sea kayaks vee bottoms. In that application, if the wear area is narrow enough, Dynel sleeve from Sweet Composites is much easier than cutting a narrow strip of Dynel fabric, and lays down tough as nails two layers at once. That sleeve may have been a Pblanc suggestion, and has proven useful in several applications beyond vee bottoms or skid plates.

Dynel sleeve here (scroll part way down)

https://www.sweetcomposites.com/Polyester.html

The “lightweight” sleeve is 1 ½” wide, the “standard weight” is 1 ¾” wide. The actually fabric “weight” seems the same, or at least I can’t tell the difference. Cutting a 16’ long strip of narrow Dynel from yards off fabric, with edge frays and my kindergarten-wobbly scissor work? Thanks, but no.

Wider Dynel sleeve or, better still, single layer Dynel in wider rolls, something like 3” or 4” wide, would be really useful, were there such a thing. I’m still searching.

With fabric and peel ply already in rolls the rest gets simpler and easier.

Boat taped and papered, bottom coat of epoxy painted on, cut-to-length Dynel sleeve unrolled on the epoxy, epoxy topcoat, let sit a while to fully saturate the fabric, maybe add a little leftover epoxy from the pot where needed, then covered and roller compressed release treated peel ply. Release treated peel ply in rolls!

Bless Glenn MacGrady for finding release treated peel ply in rolls, available in 1” wide to 6” wide. So freaking handy, not just for long narrow strips. A lot of the fabric repairs I do are long narrow cracks or linear slices. Cut me off a piece of that peel ply roll.

https://www.aircraftspruce.com/catal...es/peelply.php

That keel strip may sound like a lot of work, but the sleeve and roll peel is simple as measure to length and make a single cut. Snip, snip, fabric and peel ply both ready to go.

I want the peel ply roll 2” wider than the keel strip epoxy width, so if I get a little catawampus unrolling it over the epoxy it will still cover the area side-to-side. When unrolling a long arsed peel ply keel strip it really pays to have a helper standing at one stem, eyeing along the keel line and calling out slight peel ply alignment adjustments as you unroll; it is hard to gauge the center line while standing alongside the hull, and better to keep true along the full length.

Peel ply in rolls is much easier than cutting long thin strips of release treated peel ply. BTW, the white peel ply that looks too much like 4oz glass (mark it as peel ply somehow, it’s hard to tell later) is easier to cut cleanly than the thinner blue stuff.

Whitewater canoes will often wear through at the center before they do at the stems. That is where the hull draws the most water in a highly rockered design, and is also where the paddler's weight is concentrated. That creates a lot of abrasion as the canoe goes over rocky ledges and shelves.

I have needed to install an exterior “football” of fabric on two old WW canoes worn near through at center, a kevlar Starburst freebie (thanks Pete Staehling), and a friend’s WW solo, worn scary thin under the saddle; not a lot of hull flexibility when grinding over rocks with paddler weight on a floor mounted saddle.

Said friend provided the fabric, something then new to me called “Dynel”. I used some thick 6oz S-glass on the first; coulda shoulda woulda used Dynel, but didn’t know there was such a thing as Dynel

Dang, this is making me long for another beater to rebuild.