Progress report, prior to priming and painting:

Outwale blanks were milled to the correct rabbet to fit the planking and canvas thickness, then steamed to fit. At the ends of the canoe, the outwales were tapered both in height and depth to arrive at a more pleasing appearance than the typical Chestnut outwales which are often left at full thickness at the ends. This early Chestnut had delicately proportioned, full length inwales which I matched with the new Spruce inwales, but the presumably factory installed Ash outwales which were unevenly shaped. In fact, I believe the factory installed one side upside down with the wider dimension on top rather than on the side. The angled cut back ends at the stem bands were also less than symmetrical. I therefore decided to make new outwales, also full length like the originals (Chestnuts often have scarfed 2-piece outwales). The rabbet was tapered back as well in the last 12" so that at the ends one doesn't see the rabbet, but just a 1/2" x 5/8" rectangular profile which was then rounded top and bottom. The outwale shaping was all done by hand with planes, scrapers, rasps, and sandpaper after the outwales were screwed to the hull.

Steaming was time consuming but entertaining, done with the steam-in-the-bag method, in four sequences for each of the four quarters of the hull.

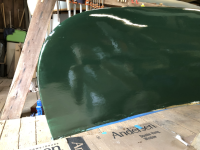

I chose to do the outwale shaping while the hull was still at the filler stage so that finish paint wouldn't be damaged by the heat of steaming. While the outwales are off the boat for priming and painting, I made a frame to hold and maintain the hard-won shape of the outwales. This is to avoid spring-back and hopefully allow re-installation on the finished hull with little to no force needed to resume it's finished shape.

I can see the finish line ahead for this long project. Paint, stem bands, and varnish remain. Oh, this canoe will be painted Kirby's #13 Blind Green. It will be my first green canoe!