G

Guest

Guest

I had a little more EZ-Poxy painting to do, might as well touch up the teeny black stripe drips on the red stems.

PB130052 by Mike McCrea, on Flickr

PB130052 by Mike McCrea, on Flickr

Who would ever even notice? I would notice; I saw, still see, every flaw, miscue and blemish on every canoe I have ever rebuilt. I expect the other builders and rebuilders out there see the same. Little tape, couple seconds with a tiny paintbrush, much better. Like anyone would ever have noticed.

PB130055 by Mike McCrea, on Flickr

PB130055 by Mike McCrea, on Flickr

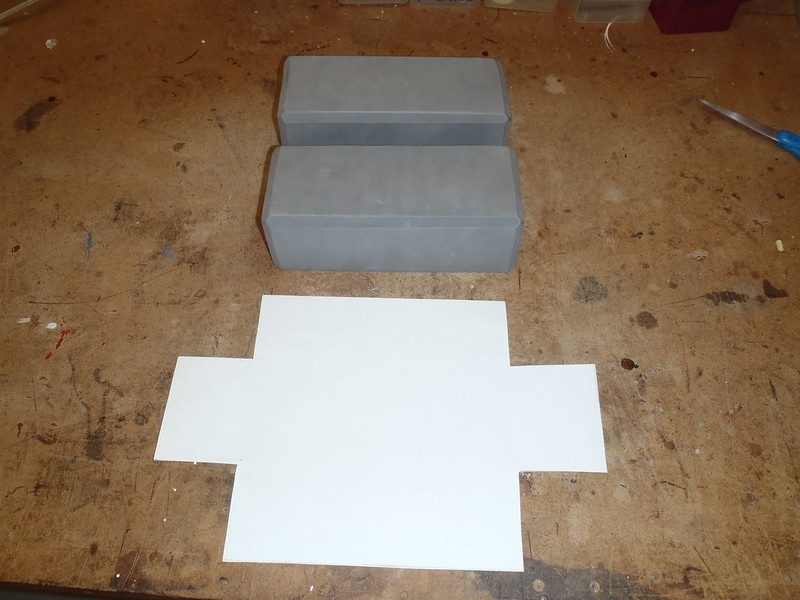

While I had the paint out I remembered something about a custom painted paddle to match the FreeFIRE. Why not, shop Gogetch and all.

PB130056 by Mike McCrea, on Flickr

PB130056 by Mike McCrea, on Flickr

It is one of those silly paddles that is missing one blade, but it would still make a good spare.

Before the brightwork went back on, while I had finish-washer-free inwales, I re-oiled the gunwales, using “Arkey” mix, named after the fellow who introduced it to me (he may actually have been “RK”).

PB140077 by Mike McCrea, on Flickr

PB140077 by Mike McCrea, on Flickr

Equal amounts of boiled linseed oil, turpentine and spar varnish, a little heavier on the turps for the first raw wood coat. That mix is a great use for the last dregs of spar varnish in a can. Or even a dried up hockey puck of spar varnish in a can. A few years ago I added a little more turps and linseed oil (and, what the hell, a splash of leftover Tung oil) to the can and dropped in a hockey puck of dried varnish.

That varnish puck had totally dissolved over time. A little light sanding, wipe on, let sit, wipe off. Inside all the inwale holes too. Oops, in that careful sanding I discovered a few very small places that the red EZ-Poxy had in fact seeped through the tape. A bit of acetone and 0000 steel wool took off the wee paint dribbles.

Once that dried sufficiently I could reinstall all of the now-walnut brightwork. Four or five different woods, there is a little color difference and a lot of difference in the stained grain.

PB140079 by Mike McCrea, on Flickr

PB140079 by Mike McCrea, on Flickr

The re-oiled gunwales look nice, now Arkay (RK) re-oiled and good for many years to come. Although, now with superior outfitting, the FreeFIRE will likely get used more often, and maybe I’ll swipe a little oil on the gunwales with more regularity.

Starting at the ends, installing the two standard thwarts first. Bar clamps again to draw the sheerline back to where it should be.

PB150006 by Mike McCrea, on Flickr

PB150006 by Mike McCrea, on Flickr

Then the combination foot brace/sail thwart. I needed to “dress” that thwart first; sail mount as before, but adding an over/under/over run of bungee, and a open cam cleat to hold the bowline in reach handy. Good quality ¼” woven sheath bungee, from Tom at Top Kayaker:

http://topkayaker.com/index.php?main_page=product_info&cPath=2_19&produc ts_id=403

Staying true to the red & black only color scheme I had spray painted the heads of the SS sail mount bolts and cam cleat screws.

PB150001 by Mike McCrea, on Flickr

PB150001 by Mike McCrea, on Flickr

PB150010 by Mike McCrea, on Flickr

PB150010 by Mike McCrea, on Flickr

I wanted a spacer ball on one side of that thwart bungee, but have no walnut stain on my balls, and wasn’t waiting around to stain and urethane one, so au natural it is. No deck compass for that foot brace/sail thwart as per usual; it wasn’t shaped to accommodate one, and the Missus or son would be kicking it with their feet.

In a completely anal move (no surprise there) I took the SS pad eyes off the edge of the deck plate ends and spray painted them, and the screw heads, black. I would have reinstalled black nylon pad eyes in their place, but the hole spacing was different. I’m not entirely certain what purpose they serve, but I put them there 20 years ago, and didn’t want to leave the screw holes open.

PB150016 by Mike McCrea, on Flickr

PB150016 by Mike McCrea, on Flickr

With the various thwarts holding the sheerline back in position the seat went in. Those wee rubber washers were a godsend to hold the four Conk seat drops in place. I really like the look of those Conk laminated seat drops.

PB150009 by Mike McCrea, on Flickr

PB150009 by Mike McCrea, on Flickr

dang but everything goes back in easy peezy when it has been test fitted first. Eh, I did start to install the ever so slightly canted seat drops incorrectly, but caught that error before any washers or nuts went on.

Hell, I like the refreshed look of the whole canoe, even with five different shades of walnut (and one blond ball). Every piece of brightwork is well fitted and every machine screw has washers, Nylocks and cap washers.

PB150017 by Mike McCrea, on Flickr

PB150017 by Mike McCrea, on Flickr

I didn’t use as many webbing loop tie downs as anticipated. No need for them on the short carry handles, no desire for them on the foot brace thwart or seat, where they might, possibly (never yet happened) snag a boot lace hook. On the standard thwarts only, so I have a couple dozen pre-made to put wherever I want on the Pathfinder. Maybe I’ll pop rivet them under the gunwales every six inches. BWAHAHAHA!

PB130052 by Mike McCrea, on Flickr

PB130052 by Mike McCrea, on FlickrWho would ever even notice? I would notice; I saw, still see, every flaw, miscue and blemish on every canoe I have ever rebuilt. I expect the other builders and rebuilders out there see the same. Little tape, couple seconds with a tiny paintbrush, much better. Like anyone would ever have noticed.

PB130055 by Mike McCrea, on Flickr

PB130055 by Mike McCrea, on FlickrWhile I had the paint out I remembered something about a custom painted paddle to match the FreeFIRE. Why not, shop Gogetch and all.

PB130056 by Mike McCrea, on Flickr

PB130056 by Mike McCrea, on FlickrIt is one of those silly paddles that is missing one blade, but it would still make a good spare.

Before the brightwork went back on, while I had finish-washer-free inwales, I re-oiled the gunwales, using “Arkey” mix, named after the fellow who introduced it to me (he may actually have been “RK”).

PB140077 by Mike McCrea, on Flickr

PB140077 by Mike McCrea, on FlickrEqual amounts of boiled linseed oil, turpentine and spar varnish, a little heavier on the turps for the first raw wood coat. That mix is a great use for the last dregs of spar varnish in a can. Or even a dried up hockey puck of spar varnish in a can. A few years ago I added a little more turps and linseed oil (and, what the hell, a splash of leftover Tung oil) to the can and dropped in a hockey puck of dried varnish.

That varnish puck had totally dissolved over time. A little light sanding, wipe on, let sit, wipe off. Inside all the inwale holes too. Oops, in that careful sanding I discovered a few very small places that the red EZ-Poxy had in fact seeped through the tape. A bit of acetone and 0000 steel wool took off the wee paint dribbles.

Once that dried sufficiently I could reinstall all of the now-walnut brightwork. Four or five different woods, there is a little color difference and a lot of difference in the stained grain.

PB140079 by Mike McCrea, on Flickr

PB140079 by Mike McCrea, on FlickrThe re-oiled gunwales look nice, now Arkay (RK) re-oiled and good for many years to come. Although, now with superior outfitting, the FreeFIRE will likely get used more often, and maybe I’ll swipe a little oil on the gunwales with more regularity.

Starting at the ends, installing the two standard thwarts first. Bar clamps again to draw the sheerline back to where it should be.

PB150006 by Mike McCrea, on Flickr

PB150006 by Mike McCrea, on FlickrThen the combination foot brace/sail thwart. I needed to “dress” that thwart first; sail mount as before, but adding an over/under/over run of bungee, and a open cam cleat to hold the bowline in reach handy. Good quality ¼” woven sheath bungee, from Tom at Top Kayaker:

http://topkayaker.com/index.php?main_page=product_info&cPath=2_19&produc ts_id=403

Staying true to the red & black only color scheme I had spray painted the heads of the SS sail mount bolts and cam cleat screws.

PB150001 by Mike McCrea, on Flickr

PB150001 by Mike McCrea, on Flickr PB150010 by Mike McCrea, on Flickr

PB150010 by Mike McCrea, on FlickrI wanted a spacer ball on one side of that thwart bungee, but have no walnut stain on my balls, and wasn’t waiting around to stain and urethane one, so au natural it is. No deck compass for that foot brace/sail thwart as per usual; it wasn’t shaped to accommodate one, and the Missus or son would be kicking it with their feet.

In a completely anal move (no surprise there) I took the SS pad eyes off the edge of the deck plate ends and spray painted them, and the screw heads, black. I would have reinstalled black nylon pad eyes in their place, but the hole spacing was different. I’m not entirely certain what purpose they serve, but I put them there 20 years ago, and didn’t want to leave the screw holes open.

PB150016 by Mike McCrea, on Flickr

PB150016 by Mike McCrea, on FlickrWith the various thwarts holding the sheerline back in position the seat went in. Those wee rubber washers were a godsend to hold the four Conk seat drops in place. I really like the look of those Conk laminated seat drops.

PB150009 by Mike McCrea, on Flickr

PB150009 by Mike McCrea, on Flickrdang but everything goes back in easy peezy when it has been test fitted first. Eh, I did start to install the ever so slightly canted seat drops incorrectly, but caught that error before any washers or nuts went on.

Hell, I like the refreshed look of the whole canoe, even with five different shades of walnut (and one blond ball). Every piece of brightwork is well fitted and every machine screw has washers, Nylocks and cap washers.

PB150017 by Mike McCrea, on Flickr

PB150017 by Mike McCrea, on FlickrI didn’t use as many webbing loop tie downs as anticipated. No need for them on the short carry handles, no desire for them on the foot brace thwart or seat, where they might, possibly (never yet happened) snag a boot lace hook. On the standard thwarts only, so I have a couple dozen pre-made to put wherever I want on the Pathfinder. Maybe I’ll pop rivet them under the gunwales every six inches. BWAHAHAHA!