G

Guest

Guest

Minicel, Dragonskin and contact cement day

It was time to start on some of the comfort outfitting, minicel pads for bracing my knees, pads for my heels on the bottom and my toes on the rudder controls. This necessitated putting the Comrade on the test-sit pad on the shop floor and making some areas for minicel. The sliding seat meant that some of those pads be longer than usual.

12” long knee bumpers, rather than the usual 6” length that works with a fixed seat. A bit of band saw work and some custom Dragonskin carving and I had the necessary pieces made from a scrap box length of ½” minicel. I wanted real outfitting minicel for the knee bumper to provide some serious cushion for the pushin’.

To get the knee brace spread I wanted an inch of minicel on each side, and I needed to cover the cockpit coming “dimples”, which stick out exactly where my knees hit with the seat furthest back. Two overlaid ½” thick pieces did the trick.

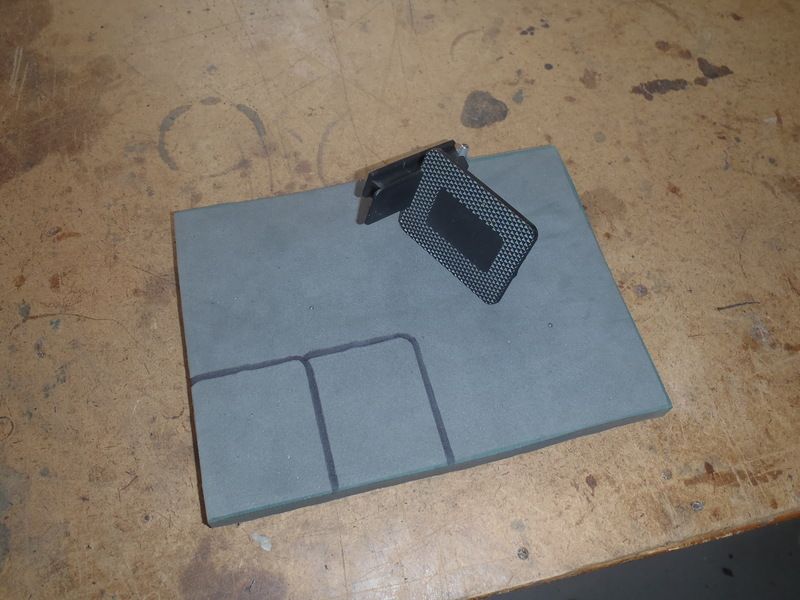

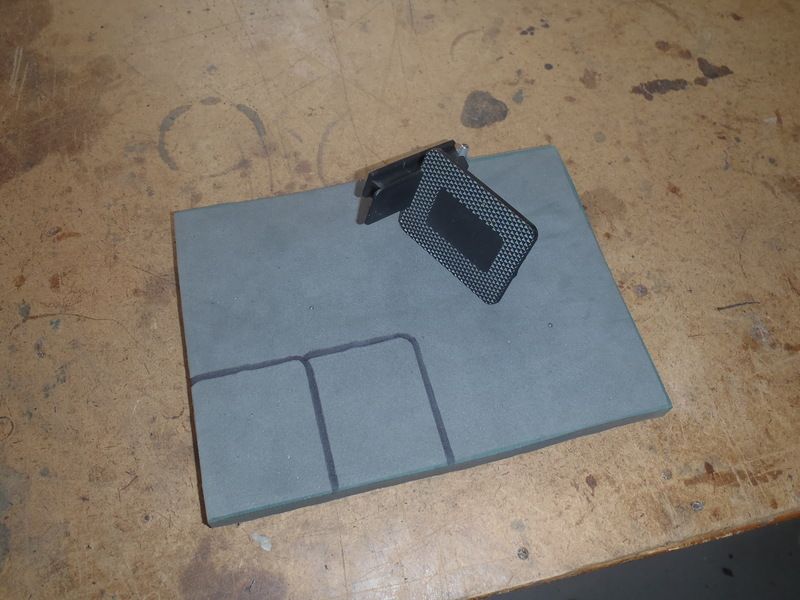

I’m a comfort wuss. Sometimes a barefoot comfort wuss. I want padding on the foot pedals as well. A couple of wee pieces cut from scrap exercise flooring will do nicely.

As a sometimes barefoot wuss I also want some padding under my heels. That padding is not only a comfort issue, it helps keep my heels or shoes from sliding when braced in a wet hull. In thin-skinned composite canoes I think of those minicel heel pads as a sacrificial layer; I’d rather wear down a couple bucks worth of minicel than a couple thousand in boat bottom.

Those too were bigger than usual, 12” x 9”. Outfitting minicel is cushier than exercise flooring, exercise flooring is more durable (embossed side out) than standard minicel. I couldn’t bring myself to cut those oversized pieces from a virgin chunk of outfitting foam, so exercise flooring it was.

Oh, what the hell. While I was getting foamy and ready for a contact cement session I decided to install RidgeRest padding on the bucket seat. The Grade VI pad is plenty cushy, but it is one more thing I would need to remember to bring, and one more thing to install before launching. I know how bad my memory is, and how strong my urge to get gone and not have to futz with outfitting once I reach a put in.

I came up a tiny bit short for full seat pan coverage on the last remaining scrap of RidgeRest foam. Wabi-sabi good enough, and waste not, want not. And there wasn’t a lot of wastage. Two-tone Wabi-sabi, or maybe that’s Yin Yang; the RidgeRest scrap wasn’t big enough to cut into color matching sides.

With all of the application areas cleaned with alcohol it was time to set the exhaust fan and make some contact cement stink in the shop.

Whole lotta gluing going on. The push pins in the RidgeRest foam are to keep it from curling up in between coats of contact cement. The usual timed multiple coats, three on the foam, two on the hard surfaces, dried ‘til just barely tacky, flashed with a heat gun, stuck in place and weighted or clamped in place.

I walked away overnight and next morning laid a bead of Plumber’s Goop around all of the minicel edges for a better edge seal and resistance to shear forces.

It was time to start on some of the comfort outfitting, minicel pads for bracing my knees, pads for my heels on the bottom and my toes on the rudder controls. This necessitated putting the Comrade on the test-sit pad on the shop floor and making some areas for minicel. The sliding seat meant that some of those pads be longer than usual.

12” long knee bumpers, rather than the usual 6” length that works with a fixed seat. A bit of band saw work and some custom Dragonskin carving and I had the necessary pieces made from a scrap box length of ½” minicel. I wanted real outfitting minicel for the knee bumper to provide some serious cushion for the pushin’.

To get the knee brace spread I wanted an inch of minicel on each side, and I needed to cover the cockpit coming “dimples”, which stick out exactly where my knees hit with the seat furthest back. Two overlaid ½” thick pieces did the trick.

I’m a comfort wuss. Sometimes a barefoot comfort wuss. I want padding on the foot pedals as well. A couple of wee pieces cut from scrap exercise flooring will do nicely.

As a sometimes barefoot wuss I also want some padding under my heels. That padding is not only a comfort issue, it helps keep my heels or shoes from sliding when braced in a wet hull. In thin-skinned composite canoes I think of those minicel heel pads as a sacrificial layer; I’d rather wear down a couple bucks worth of minicel than a couple thousand in boat bottom.

Those too were bigger than usual, 12” x 9”. Outfitting minicel is cushier than exercise flooring, exercise flooring is more durable (embossed side out) than standard minicel. I couldn’t bring myself to cut those oversized pieces from a virgin chunk of outfitting foam, so exercise flooring it was.

Oh, what the hell. While I was getting foamy and ready for a contact cement session I decided to install RidgeRest padding on the bucket seat. The Grade VI pad is plenty cushy, but it is one more thing I would need to remember to bring, and one more thing to install before launching. I know how bad my memory is, and how strong my urge to get gone and not have to futz with outfitting once I reach a put in.

I came up a tiny bit short for full seat pan coverage on the last remaining scrap of RidgeRest foam. Wabi-sabi good enough, and waste not, want not. And there wasn’t a lot of wastage. Two-tone Wabi-sabi, or maybe that’s Yin Yang; the RidgeRest scrap wasn’t big enough to cut into color matching sides.

With all of the application areas cleaned with alcohol it was time to set the exhaust fan and make some contact cement stink in the shop.

Whole lotta gluing going on. The push pins in the RidgeRest foam are to keep it from curling up in between coats of contact cement. The usual timed multiple coats, three on the foam, two on the hard surfaces, dried ‘til just barely tacky, flashed with a heat gun, stuck in place and weighted or clamped in place.

I walked away overnight and next morning laid a bead of Plumber’s Goop around all of the minicel edges for a better edge seal and resistance to shear forces.