G

Guest

Guest

Thanks to Mad Mike for finding it and DougD for fronting the cash and hauling it from New Hampshire to Maryland, I have a summer shop rebuild project. A 1976 Klepper Kamerad TS (Tandem Sailing) kayak with rudder.

https://www.google.com/search?q=kle...e%2Fpaddeln%2Fklepper_kamerad_ts.html;931;740

Woven roving, glass and gel coat, 5’ 11” long x 30” max width. Purportedly 73 lbs from the factory, if my kg to lb conversion is correct.

Doug stripped out the antique Klepper seats, and the Kamerad weighed it at 68 lbs in the shop, but there is still a lot of glassed in hardware to remove.

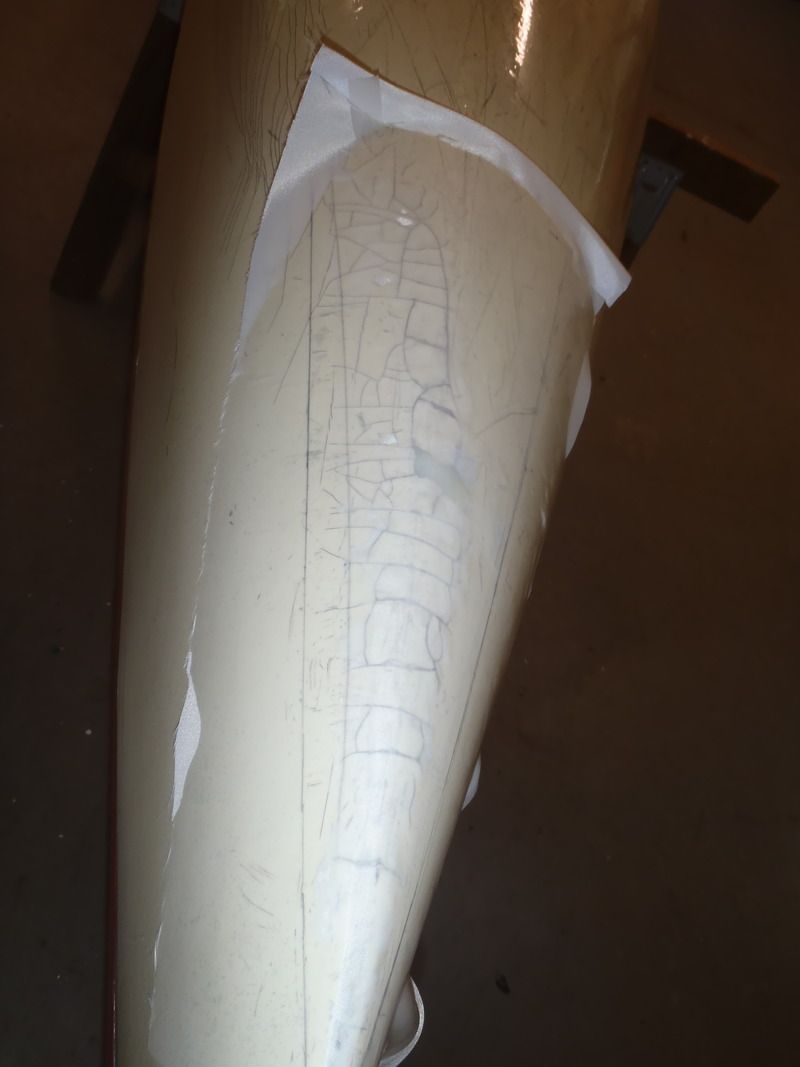

Day 1 of the gut. Starting with the 9 foot long by 9 inch wide fiberglass track to which the OEM seats were fastened. I can pry that sucker up a bit in the center, but the ends are well glassed. (I didn’t know how well ‘til I got them free and could see the puddles of thickened resin and wood support blocks affixed below)

Fugly.

Between a Dremel tool, sharp putty knife, a couple of hacksaw blades with duct tape grips, lots of elbow grease and a few swear words I had it cut out. I left the bow portion with the mast step; thinking I might eventually use that step and hardware with a real mast.

And then, after carefully Dremeling that end to leave the OEM mast step in place, I took it out as well. If I ever move on to a real tack-into-the-wind sail (doubtful) I’ll install my own step below the mast hole in the foredeck.

That seat and mast step panel was fiberglass, with some plywood supports glassed in underneath. There’s 5.5 lbs gone.

The Kamerad has lots of other sailing and seat attachment hardware that needs to be removed. Four cleats, 6 eye screws, four pad eyes and a partridge in a pear tree, most of which resisted drilling out and needed to be hack sawed and Dremeled free. And that just the stuff I can reach with the hull right side up.

The Kamerede (I want to put extra e’s in that) had 8 feet of spring loaded doohickeies (German technical term) glassed along each side to hold floatation under the cockpit coming. Hoo-effing-ray, those things pulled free with their glass strips sans any cutting or Dremeling.

That’s a lot of unnecessary appendages for modern soloization. Another 18 oz removed

That was a mess of antique OEM outfitting.

The Klepper already needs a better name. Or at least an easier name; I have trouble spelling Kamerad and want to put an E on the end, or somewhere in the middle. Maybe English would be easier; The Comrade. Wait, it won’t be a TS Tandem Sailing hull, but a solo boat. Meh, Comrade SS may be a little too WWII.

Stripped of everything I can see or reach with the hull right side up it’s time to invert it on tall sawhorses and gut stuff from inside the decks.

There wasn’t as much antique outfitting on the inside, just a half dozen rings. Cunningly crafted for the times technology I suppose; a ¾” stainless ring laid flat against the hull with a stainless steel wire “padeye” laid over it, covered cloth and resin with the wire padeye part exposed and another free dangling SS ring through that.

They must have been tricky to get glassed in place all as one piece. They were sure a PITA to get out.

That’s everything out of it ‘til I go full-on PPE with sanders on the inside. Dreadful work, especially in a sweaty summer. Beyond the sanding dust I create this is the least the Comrade will ever weight. Back to the scale.

Spec’ed at 73 lbs from the factory the gutted Comrade is a hair under 60 lbs.

https://www.google.com/search?q=kle...e%2Fpaddeln%2Fklepper_kamerad_ts.html;931;740

Woven roving, glass and gel coat, 5’ 11” long x 30” max width. Purportedly 73 lbs from the factory, if my kg to lb conversion is correct.

Doug stripped out the antique Klepper seats, and the Kamerad weighed it at 68 lbs in the shop, but there is still a lot of glassed in hardware to remove.

Day 1 of the gut. Starting with the 9 foot long by 9 inch wide fiberglass track to which the OEM seats were fastened. I can pry that sucker up a bit in the center, but the ends are well glassed. (I didn’t know how well ‘til I got them free and could see the puddles of thickened resin and wood support blocks affixed below)

Fugly.

Between a Dremel tool, sharp putty knife, a couple of hacksaw blades with duct tape grips, lots of elbow grease and a few swear words I had it cut out. I left the bow portion with the mast step; thinking I might eventually use that step and hardware with a real mast.

And then, after carefully Dremeling that end to leave the OEM mast step in place, I took it out as well. If I ever move on to a real tack-into-the-wind sail (doubtful) I’ll install my own step below the mast hole in the foredeck.

That seat and mast step panel was fiberglass, with some plywood supports glassed in underneath. There’s 5.5 lbs gone.

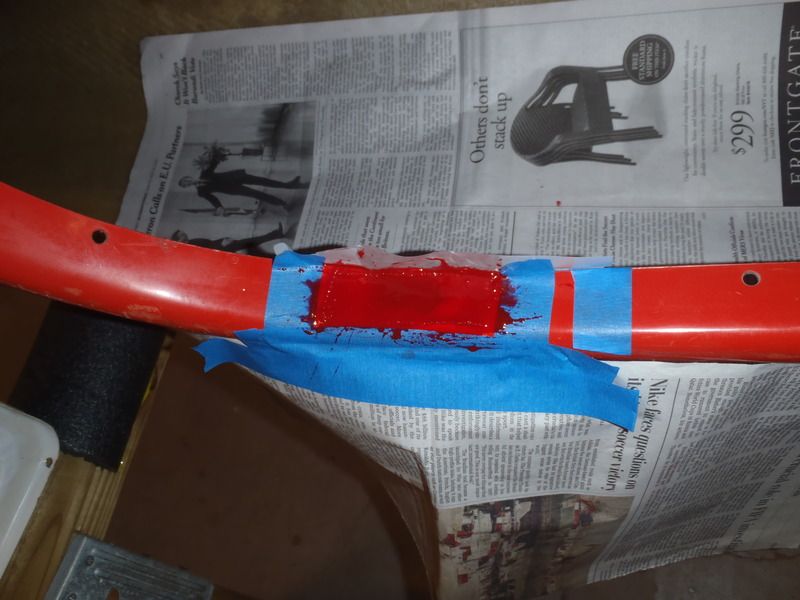

The Kamerad has lots of other sailing and seat attachment hardware that needs to be removed. Four cleats, 6 eye screws, four pad eyes and a partridge in a pear tree, most of which resisted drilling out and needed to be hack sawed and Dremeled free. And that just the stuff I can reach with the hull right side up.

The Kamerede (I want to put extra e’s in that) had 8 feet of spring loaded doohickeies (German technical term) glassed along each side to hold floatation under the cockpit coming. Hoo-effing-ray, those things pulled free with their glass strips sans any cutting or Dremeling.

That’s a lot of unnecessary appendages for modern soloization. Another 18 oz removed

That was a mess of antique OEM outfitting.

The Klepper already needs a better name. Or at least an easier name; I have trouble spelling Kamerad and want to put an E on the end, or somewhere in the middle. Maybe English would be easier; The Comrade. Wait, it won’t be a TS Tandem Sailing hull, but a solo boat. Meh, Comrade SS may be a little too WWII.

Stripped of everything I can see or reach with the hull right side up it’s time to invert it on tall sawhorses and gut stuff from inside the decks.

There wasn’t as much antique outfitting on the inside, just a half dozen rings. Cunningly crafted for the times technology I suppose; a ¾” stainless ring laid flat against the hull with a stainless steel wire “padeye” laid over it, covered cloth and resin with the wire padeye part exposed and another free dangling SS ring through that.

They must have been tricky to get glassed in place all as one piece. They were sure a PITA to get out.

That’s everything out of it ‘til I go full-on PPE with sanders on the inside. Dreadful work, especially in a sweaty summer. Beyond the sanding dust I create this is the least the Comrade will ever weight. Back to the scale.

Spec’ed at 73 lbs from the factory the gutted Comrade is a hair under 60 lbs.