To parse Glenns distain for skid plates

However, I think skid plates are complete waste of time, money and hull performance.

Time. Installing those Dynel skid plates took but a few hours, some of that wait time.

Money. I could probably calculate the materials cost of the various Dynel, peel ply, epoxies and graphite powder. That might take more time than the actual installation. Since I keep all of those materials available in the shop, probably less than $20, most of that in Gflex cost.

I do agree that a thicker, heavier, uglier 100 dollar skid plate kit is a waste of money.

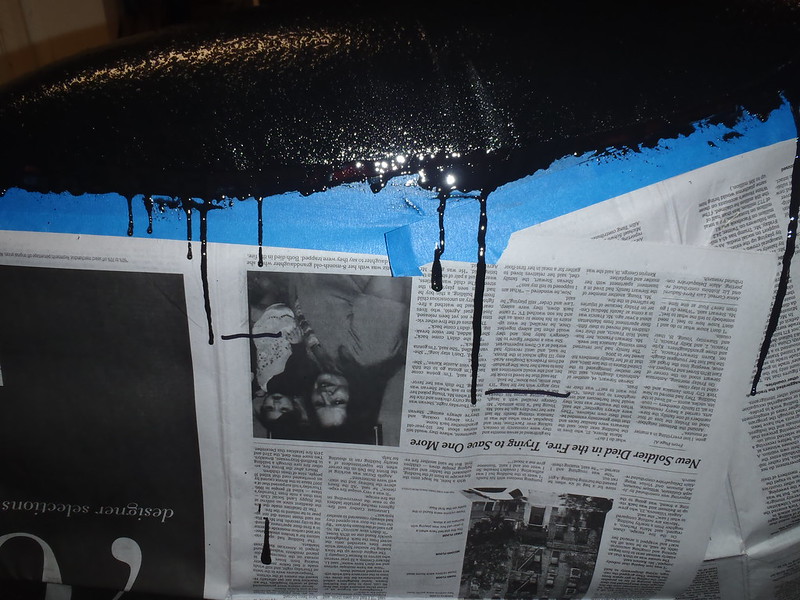

Hull performance. A single layer Dynel skid plate, compressed under peel ply, is dang near flush with the hull, and may add a couple of ounces to each stem. The Dynel cloth and spoonful of graphite powder weigh almost nothing. Just to check I filled a mixing cup with an epoxy equivalent amount of water. Approximately 1 cup, or 8 ounces. The epoxy and graphite mix is lighter than water, and after subtracting the drips on the newspaper and the more considerable volume of epoxy that comes off on the two tape layers, maybe 4 ounces per skid plate.

I put Kevlar skid plates on my first canoe, a Mad River Royalex Explorer. Never again.

Me too, never again. But a single layer of peel ply compressed Dynel is quite unlike a swollen kevlar felt beast.

None of my 15 or 16 canoes have gotten damaged on the stems, not even my aggressively paddled whitewater canoes. Those have worn under the central seat, gotten wrapped, had gunwales broken, but no significant wear on the stems.

Most of my 15 or 16 canoes had shown wear at the stems before I installed skid plates, even my unaggressively paddled Class 1 boats. The Royalex ones especially.

The skid plates will alter the smooth, laminar flow of water around the bow, and they will add weight in the worst possible place for maneuverability -- inertial swing weight at the ends of the hull.

See hull performance above regarding altering the laminar flow to any significant degree. The scratches on the bottom of most of my boats have more effect. See an estimated couple ounces added to each stem above regarding inertial swing weight.

Skid plates are ugly. I don't like my canoes deliberately made ugly.

Some skid plates are ugly. Poorly installed, untinted kevlar felt skid plates come to mind. A skid plate does not need to be that ugly. Dynel tinted white on a white bottomed hull will be nearly invisible, especially after topcoating with white paint.

I usually do not try to color match red or green hulls, but use black pigment and graphite powder for black skid plates. Once topcoated with black paint and sharp edge line those skid plates are not unappealing to me, even though black shows every imperfection.

Finally, treat your canoe with respect and care so it doesn't become damaged on the stems or anywhere else, if you can avoid it. Don't ram your canoe onto the shore. Get in and out of the canoe while it is in the water. In other words, "wet foot" your entry and exit; canoeing is a water sport. Don't drag your canoe unless absolutely necessary. And learn moving water paddle skills and still water freestyle skills, so that you don't hit hard objects in the first place.

I do treat my canoes with respect, which is why I outfit them and maintain them. They get used, and show it. I try not to ram my boats onto shore, but landing in wind and wave sometimes necessitates sacrifices. My knees are not what they once were, and my back never was. If it is a choice to sacrifice scratching the paint on a durable skid plate or sacrificing my mobility for a week the skid plate loses every time.

I do not drag my canoe unless it is necessary, that would be silly option for moving a canoe. Necessity is in the eye of the beholder. I behold it to be necessary when the waves are pounding the boat and I against some windy shore. I know of no other way to haul the canoe ashore at a ledge landing site, especially adjacent to deep or fast moving water. And when I come to yet another beaver dam or speedbump log I am not unloading the gear, getting under the yoke, walking 10 feet, reloading the gear and paddling another 100 yards before doing it all again.

I have some moving water skills, though perhaps a complete lack of style, free or otherwise. Even with polarized sunglasses I have not managed to see every rock in the river, especially in silty or muddy waters.

I have scraped rocks even while paddling my typically crystal clear local trout stream, sometimes when the gauge is at or near Canoe Zero. Sometimes below Canoe Zero.

For me the advantages of a lightweight, flush fitted, abrasion resistant skid plate far exceeds the penalty.

Suum cuique.