After baking all day, the canoe was ready to de-mold. Drum roll........

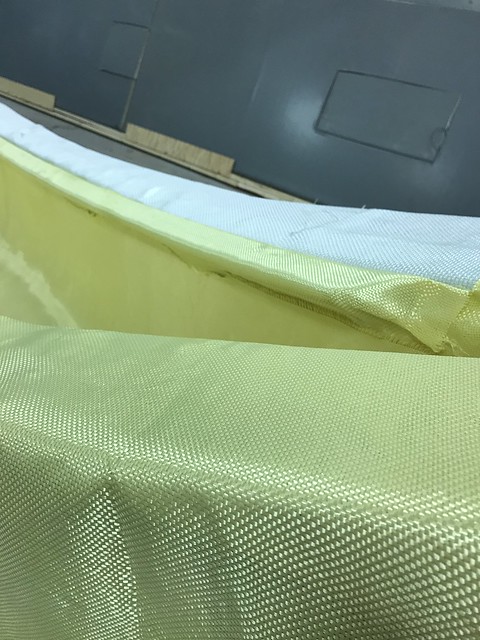

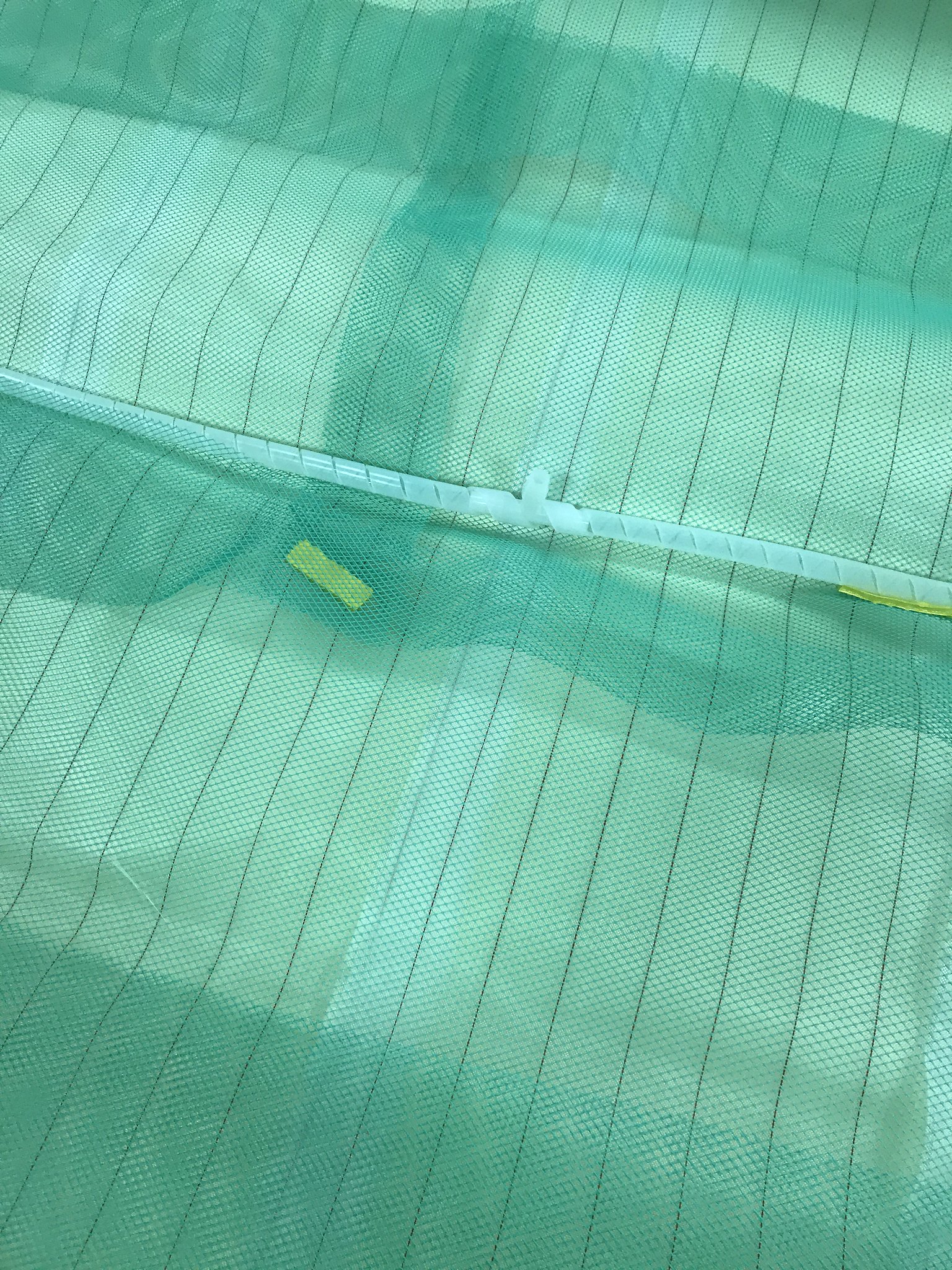

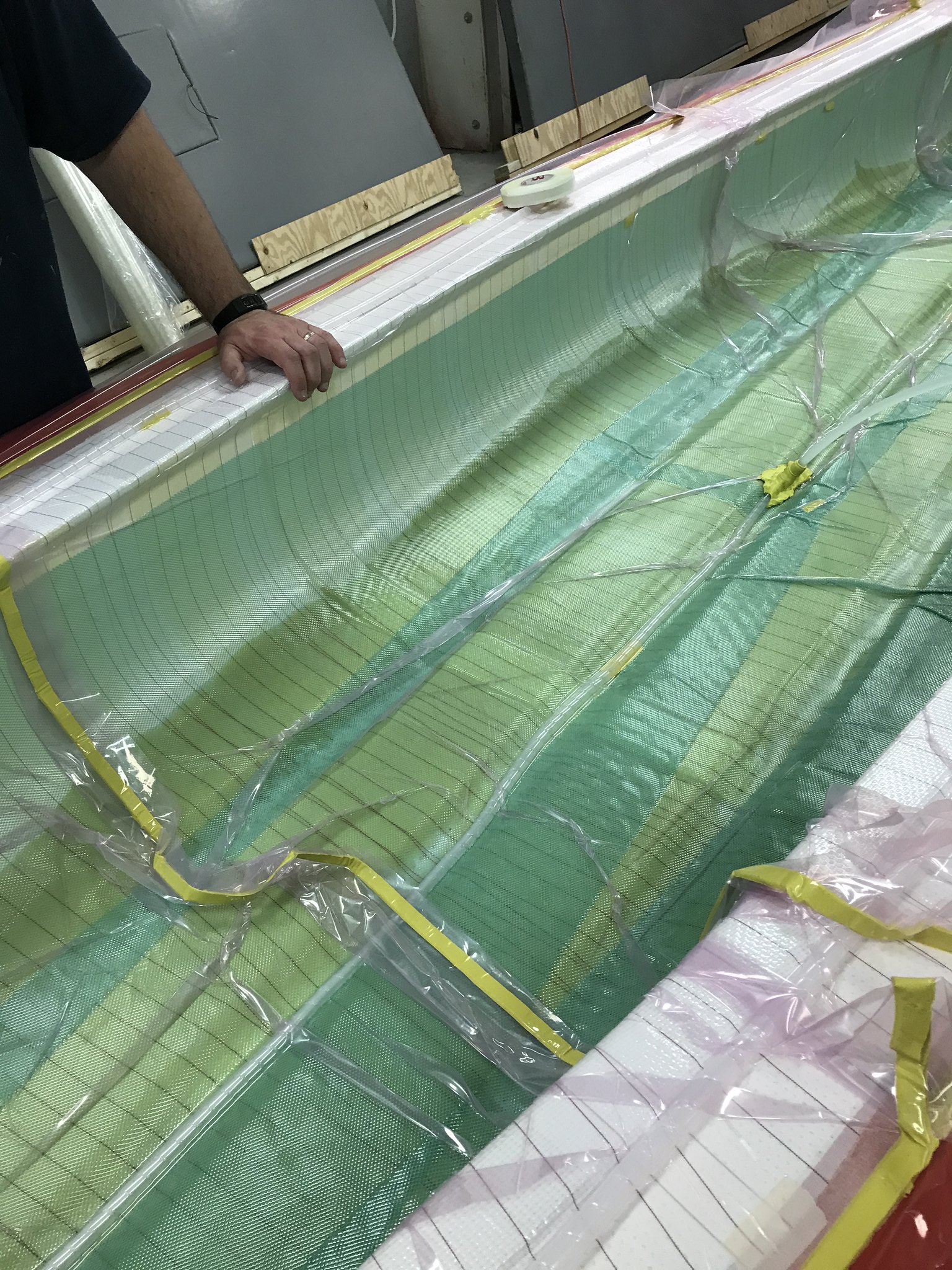

I removed the vacuum bag this morning before starting the oven cure. Once that was finished, I began removing the greenflow and peelply. Now, I have removed both before, but never from an epoxy canoe after full oven cure.....you know, where the epoxy realizes its full durability properties.

Thankfully, a couple of coworkers stuck around to help. There was blood, sweat and almost tears getting most of it off. My forearms look as though I fought off 30 cats....

IMG_2873

IMG_2873 by

bctc95, on Flickr

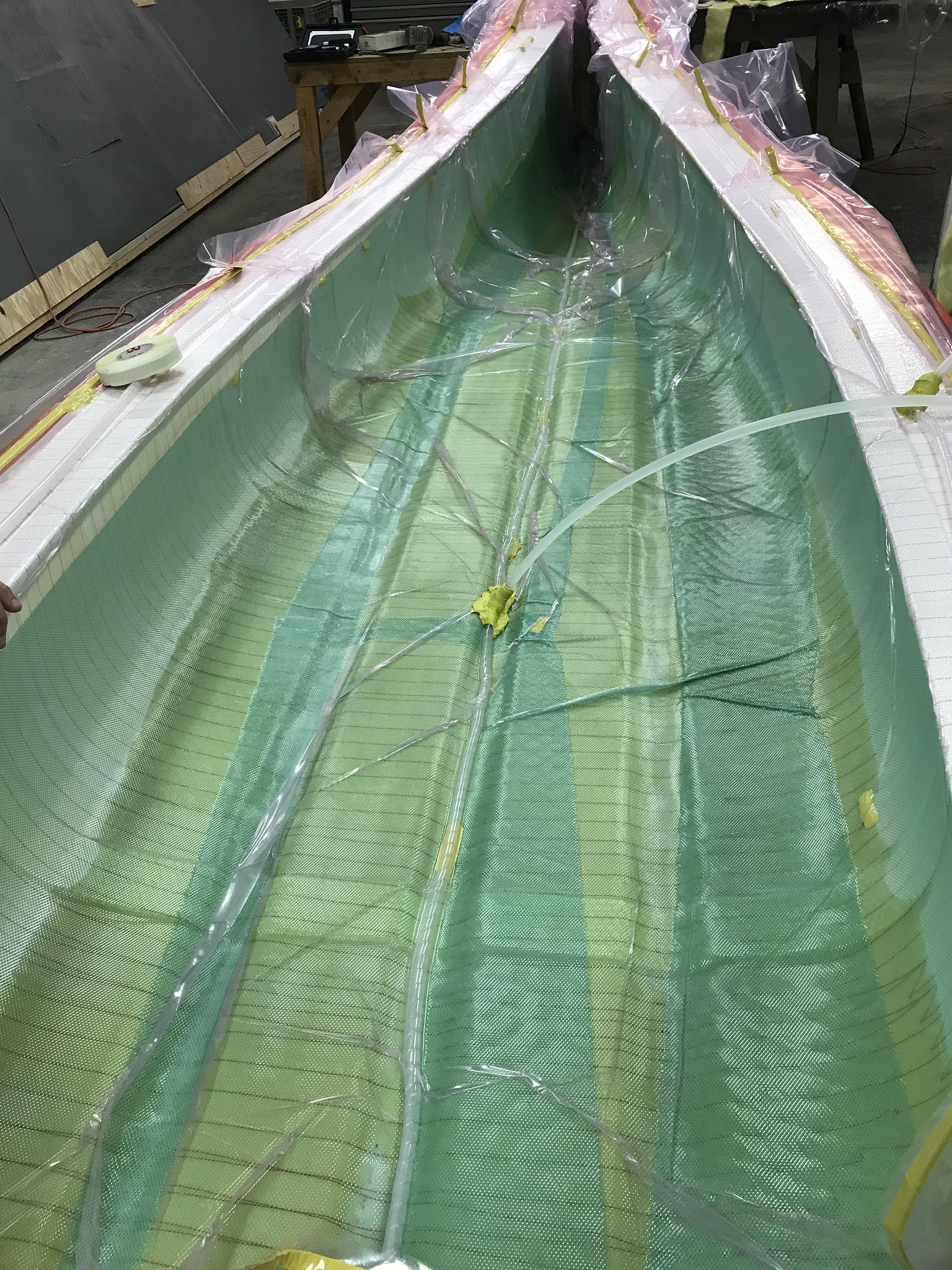

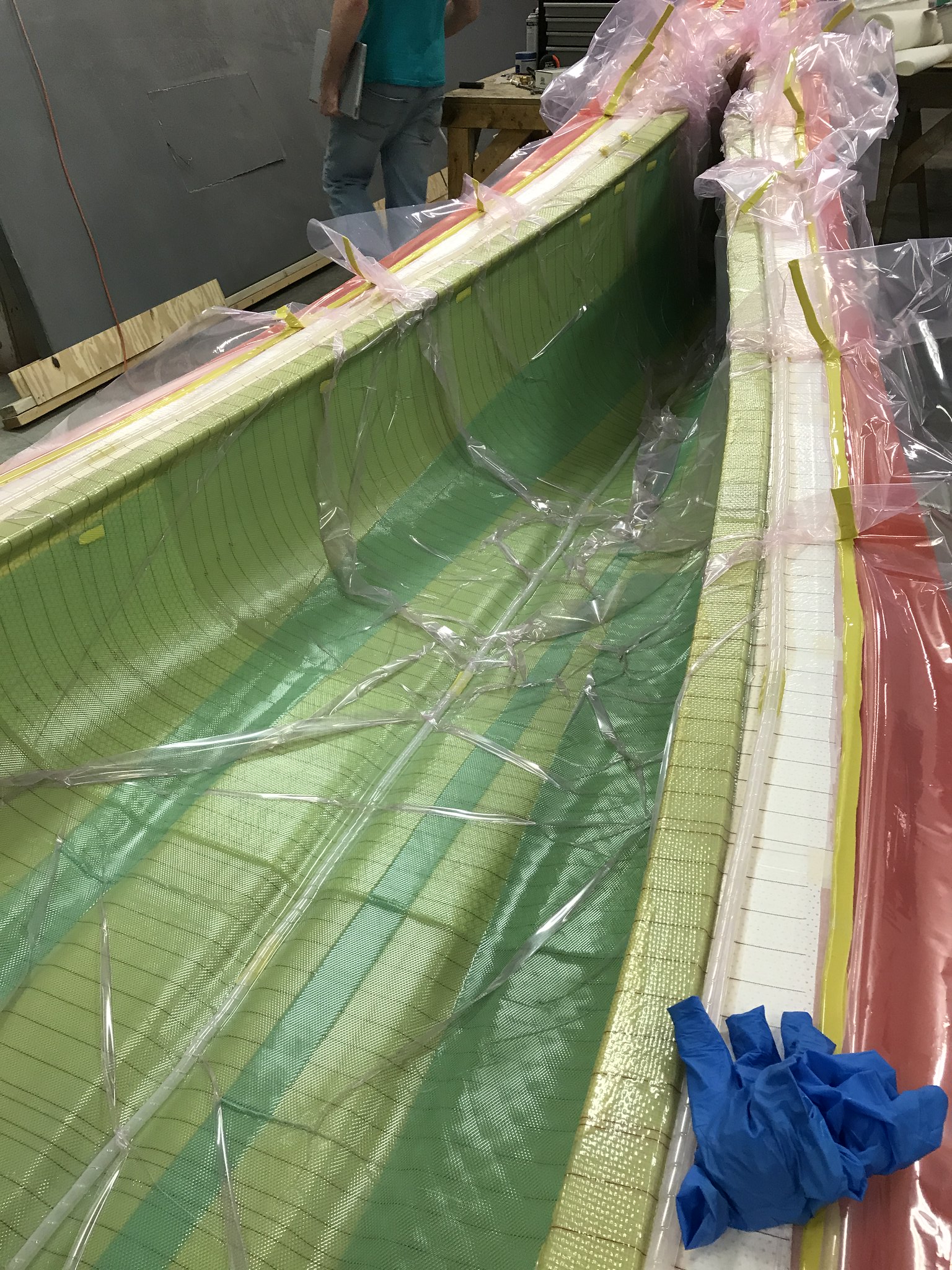

Once the epic battle was won, we separated the mold and pulled out the hull......

IMG_2875

IMG_2875 by

bctc95, on Flickr

IMG_2874

IMG_2874 by

bctc95, on Flickr

IMG_2876

IMG_2876 by

bctc95, on Flickr

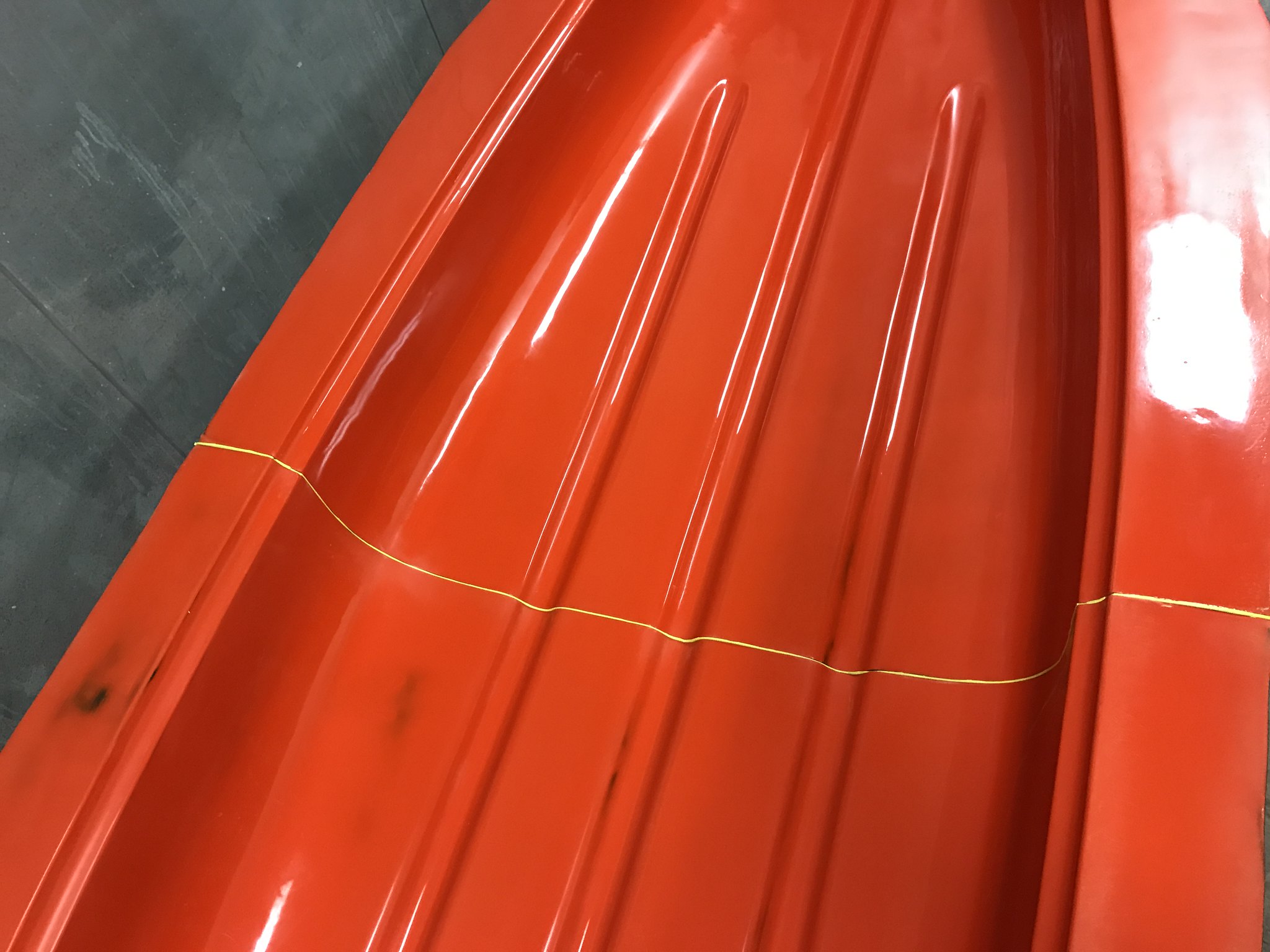

Unfortunately, there are some flaws that I am not happy about.

We had some bridging under vacuum during infusion. I had hoped that these would just fill with epoxy, rather than distort the gelcoat on the other side. There are a few wrinkles, and some deformity in the keels. Luckily, nothing a little FRP body work can't take care of.

IMG_2881

IMG_2881 by

bctc95, on Flickr

The Soric ribs are easily visible under the one layer of Kevlar.

IMG_2879

IMG_2879 by

bctc95, on Flickr

IMG_2880

IMG_2880 by

bctc95, on Flickr

IMG_2878

IMG_2878 by

bctc95, on Flickr

I need to trim off the excess material at the ends and sand the excess epoxy from the sides of the gunwales.

IMG_2885

IMG_2885 by

bctc95, on Flickr

Anybody have a suggestion for deck plates?

I can pick the canoe up over my head, but I bet it is heavier than my hopes. Once I get it cleaned up, I'll get a weight.

We are making a second canoe for my friend, so we'll make a few tweaks in the layup schedule and methods.

Now its time to mount seats, yoke, deck plates and a couple of thwarts!