Does anyone know how Colden Canoe attached there wooden decks to their wooden inwales? I don’t see any screws in any of the photos I’ve seen, so it seems as though they were epoxied on or screwed from underneath before the outwales were screwed in.

I’m refurbishing a Bell Merlin II B/G and considering alternatives to inset decks. Mostly because I made a rookie mistake and muffed-up the apex joint ! But even before that tragic turn, I was considering small wood, or thin composite plates that would keep the inwales out of the stems to prevent rot, or slow it down anyway, and leave a thin gap between the plate and the stem for drainage.

! But even before that tragic turn, I was considering small wood, or thin composite plates that would keep the inwales out of the stems to prevent rot, or slow it down anyway, and leave a thin gap between the plate and the stem for drainage.

I don’t want to go the no-deck route, I don’t have the woodworking skills to correct my mistake, and I don’t like the giant wooden caps typical of a Royalex Explorer. And plastic caps is definitely out.

The Colden decks seem more low-profile, small enough to be light weight and not split, and with the right grain add that pretty wooden jewel accent to the boat that makes girls say, “wow, that’s a nice deck!”

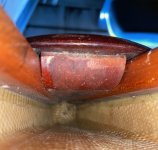

I also kinda like the idea of a composite sheet screwed to the inwales. Not quite as pretty, but very light weight, rot proof and serviceable. You can easily remove them to give the ends of the inwales a thorough oiling. Here’s an example from Millbrook Boats that I think looks pretty sharp.

I would use just one screw at the stem attached to the longer inwale that I haven’t screwed up yet. This is just black tinted fiberglass, but since the boat I’m working on has a carbon fiber exterior, I was thinking why not matching carbon fiber decks? That might keep it classy.

Curious of what you all think of the two methods, and again, if anyone knows how Colden did it.

I’m refurbishing a Bell Merlin II B/G and considering alternatives to inset decks. Mostly because I made a rookie mistake and muffed-up the apex joint

I don’t want to go the no-deck route, I don’t have the woodworking skills to correct my mistake, and I don’t like the giant wooden caps typical of a Royalex Explorer. And plastic caps is definitely out.

The Colden decks seem more low-profile, small enough to be light weight and not split, and with the right grain add that pretty wooden jewel accent to the boat that makes girls say, “wow, that’s a nice deck!”

I also kinda like the idea of a composite sheet screwed to the inwales. Not quite as pretty, but very light weight, rot proof and serviceable. You can easily remove them to give the ends of the inwales a thorough oiling. Here’s an example from Millbrook Boats that I think looks pretty sharp.

I would use just one screw at the stem attached to the longer inwale that I haven’t screwed up yet. This is just black tinted fiberglass, but since the boat I’m working on has a carbon fiber exterior, I was thinking why not matching carbon fiber decks? That might keep it classy.

Curious of what you all think of the two methods, and again, if anyone knows how Colden did it.