G

Guest

Guest

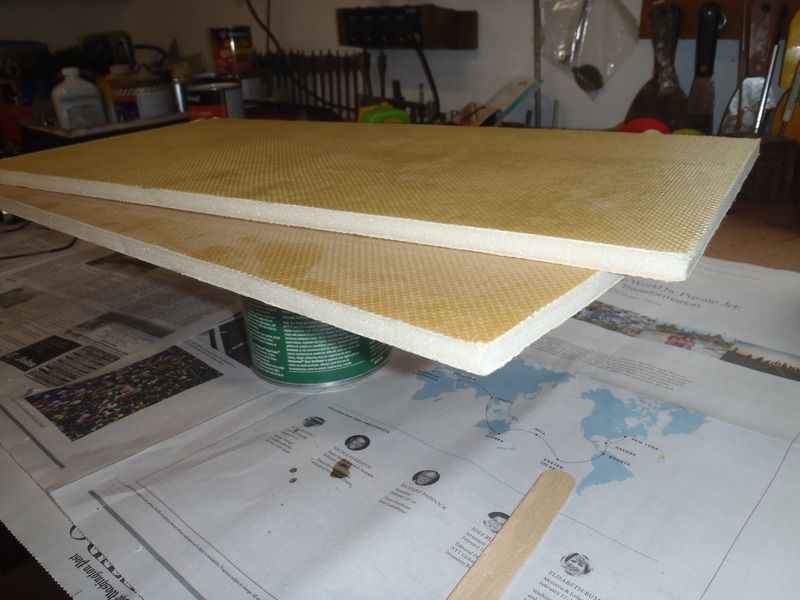

Lookie what Mr. Postman done brought me; two 10 inch x 20 inch pieces of kevlar covered foam.

Even without the squared circle excess cut away those two pieces together weigh 11 oz. I see a folding 30L tabletop that weighs less than 1lb. That is some ultra light weight and uber stiff material, only 3/8 inch thick

Yeah man! I can't wait to see the results! I was pondering the idea of a foam and fiberglass wannigan a while back but the price was way too much!

What kind of foam is in the middle of that sandwich? Something a person could purchase at a big box store?

I have no idea what kind of foam is in that kevlar sandwich, it came from a friend in the canoe business. The foam core itself is incredibly stiff, I can’t dent the foam on the raw edges with my finger nail and it takes considerable pressure to make a dent with a screwdriver.

Finished results will be a while. I need to thoroughly think this one through before I do anything rash.

I have already screwed the pooch once with that kevlar foam board. While discussing the possibility of a UL foam board tabletop I mentioned that two pieces, each 10 x 20 inches, would be “perfect”, confident that I could cut them to the squared circle shape for the 30L

The as-is edges are cut so cleanly that I really don’t want to cut it again, especially without a scrap piece to experiment on, and I’m not sure what I would use to cut thick kevlar laminated to foam without a resulting ragged mess, so it’ll be a hinged 20 inch square (with cautionary corners). In that guise it will sadly not fit inside the 30L blue barrel; I shoulda said 9 x 20

Some thoughts, questions and requests for advice on using that kevlar/foam as a tabletop, with the caveat that at 11 oz I’d like to keep any added weight to a minimum.

Both surfaces are rough textured, so the unaltered bottom should grip the minicel covered lid, but the “countertop” side will need at least a coat of epoxy and some UV protective spar urethane topcoat to make a cleanable smooth surface.

Just epoxy and urethane? Or some light S-glass, epoxy (and peel ply) before top coat? That glass layer on top would not add much weight if I’m going to epoxy the top anyway. If I add cloth I could pigment the epoxy.

The edges of those cut out pieces are exposed/untreated foam core. I’m not sure if a couple coats of epoxy would be enough to protect the foam core from abuse. The “hinged” together butt ends which provide the horizontal stiffness are a stress smush concern, and the perimeter edges are likely to see storage and transport abuse, especially since it won’t fit in the barrel. Note to self: Measure first next time.

I’m thinking some very thin 3/8 wide wood “trim” would be best, glued along those edges and epoxied/varnished over when I do the tops. Oh, look, wood gunwales on a kevlar tabletop!

Or some thin plastic strips glued on. With a poopy brown faux wood finish applied just for Brad. Those raw edges need something protective. Ideas?

Hinges? I am seriously thinking that a simple piece of high quality duct tape along the center seam after the epoxy and top coat would be enough. That would weigh nothing, and could be easily replaced if it wore out or didn’t work.

Maybe no bottom ring, just leave the rough texture for grip on the minicel barrel lid. “Maybe” because after putting the tops on a dozen times in the shop I have begun to see more and more sense in having that centering ring for ease of install.

Velcro strap attachments? I’m thinking a small machine screw through the foam board on each side, with fender washer top and bottom and nylocks.

Less than 1 lb seems within reach.