Thanks for the kind words guys; from where you sit; it probably looks like i know what im doing.

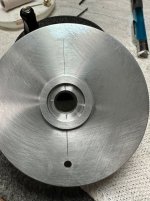

Still waiting for materials; today i finished the last two things i could. Knowing i wanted a way to identify the reel i pulled out my electro/chem etching machine; which hasn’t been used in ages and dug thru the stencils looking for something remotely applicable. Lo an behold, i had an “Alaskan Super Grade” and by removing Grade it fit well. I guess going forward this reel will be my “Alaskan Super”. It’s not entirely suitable as the name would lead you to believe this was a King Salmon reel; actually it’s only a lowly 3/4wt. Reel! But it looks cool and that’s all that really matters!

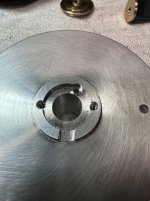

Then on to the Ratchet knob. (spool to Americano’s) The J.W Young 3 panel grip knob is hand’s down the most comfortable IMO and no self respecting Pirate would leave the good stuff behind, so I used Delrin for mine.

Still waiting for materials; today i finished the last two things i could. Knowing i wanted a way to identify the reel i pulled out my electro/chem etching machine; which hasn’t been used in ages and dug thru the stencils looking for something remotely applicable. Lo an behold, i had an “Alaskan Super Grade” and by removing Grade it fit well. I guess going forward this reel will be my “Alaskan Super”. It’s not entirely suitable as the name would lead you to believe this was a King Salmon reel; actually it’s only a lowly 3/4wt. Reel! But it looks cool and that’s all that really matters!

Then on to the Ratchet knob. (spool to Americano’s) The J.W Young 3 panel grip knob is hand’s down the most comfortable IMO and no self respecting Pirate would leave the good stuff behind, so I used Delrin for mine.

Attachments

Last edited: