The gunwales are built and glued in place. I used the same profile I've used for my last few canoes that have had carbon over cedar gunwales: 1 3/16"x3/4" with a 1/2" round over on the bottom edge and a 1/4" round over on the top. The 1/2" round over on the bottom edge with this width of gunwale is perfect as it starts the arch right where it meets the hull so there's nothing to hold the water; drains immediately when inverted.

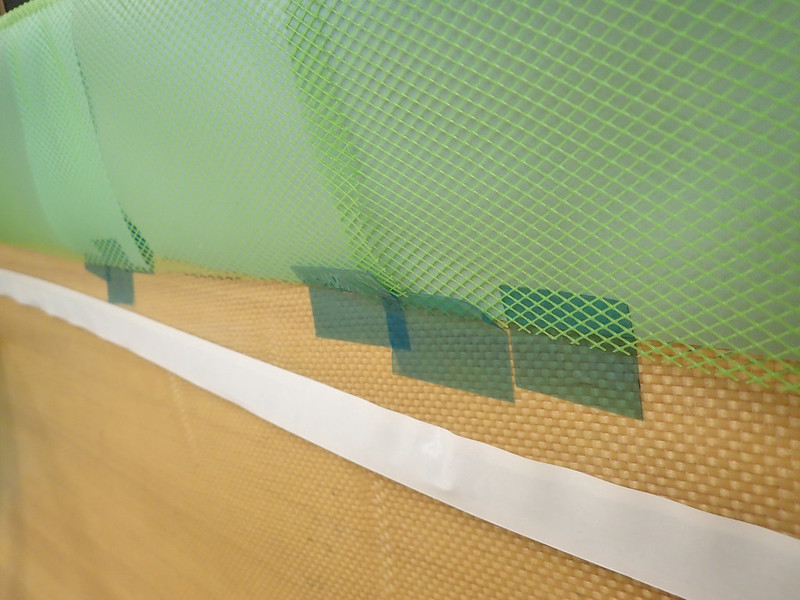

Only problem with that narrow gunwale and 1/2" round over is that it doesn't leave any flat space to attach thwarts or grab handles. Never been a problem before since I fiberglassed them in place but I don't want to do that with this time. So to give me a little extra meat I carefully measured where the thwarts and grab handles will go and glued on short pieces of 1/4" cedar strips to give me 3/4" width on the inwales in those areas. These small areas only got a 1/4" round over on the bottom instead of 1/2". Just have to hope I measured right.

20161112_005 by Alan, on Flickr

20161112_005 by Alan, on Flickr

Instead of doing two piece like the last couple I went back to a single piece gunwale. They went on pretty good except for the last 15" or so. But that's no problem. I needed to cut off the last 15" of the inwale anyway at the point it will butt into the float tank so with only the outwale still attached at the last 15" it now made the bend no problem. I was going to take a picture of this but forgot to but you can see in this picture where the inwale stops and the outwale keeps going.

20161112_002 by Alan, on Flickr

20161112_002 by Alan, on Flickr

Here's one of those blocks after milling:

20161112_001 by Alan, on Flickr

20161112_001 by Alan, on Flickr

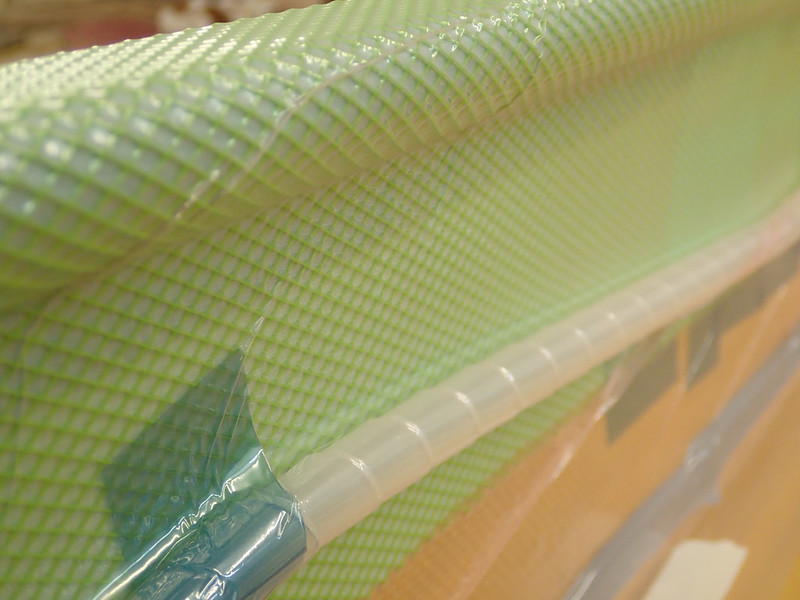

Nice thing about single piece gunwales is that it doesn't take 500 clamps to glue them in place. The clamps are only for the last 15" where it's the outwale only. Otherwise they pretty much stay in place by friction with some duct tape for good measure.

20161112_003 by Alan, on Flickr

20161112_003 by Alan, on Flickr

The slots in the gunwale are obviously oversized so I can slip it over the hull. At the bow and stern where it starts to curve towards the stems the gunwales want to tip in, kind of pigeon toed, and the oversized slots lets them do so. I added some clamps and counterweights to flatten them back out.

20161112_004 by Alan, on Flickr

20161112_004 by Alan, on Flickr

Alan

Only problem with that narrow gunwale and 1/2" round over is that it doesn't leave any flat space to attach thwarts or grab handles. Never been a problem before since I fiberglassed them in place but I don't want to do that with this time. So to give me a little extra meat I carefully measured where the thwarts and grab handles will go and glued on short pieces of 1/4" cedar strips to give me 3/4" width on the inwales in those areas. These small areas only got a 1/4" round over on the bottom instead of 1/2". Just have to hope I measured right.

20161112_005 by Alan, on Flickr

20161112_005 by Alan, on FlickrInstead of doing two piece like the last couple I went back to a single piece gunwale. They went on pretty good except for the last 15" or so. But that's no problem. I needed to cut off the last 15" of the inwale anyway at the point it will butt into the float tank so with only the outwale still attached at the last 15" it now made the bend no problem. I was going to take a picture of this but forgot to but you can see in this picture where the inwale stops and the outwale keeps going.

20161112_002 by Alan, on Flickr

20161112_002 by Alan, on FlickrHere's one of those blocks after milling:

20161112_001 by Alan, on Flickr

20161112_001 by Alan, on FlickrNice thing about single piece gunwales is that it doesn't take 500 clamps to glue them in place. The clamps are only for the last 15" where it's the outwale only. Otherwise they pretty much stay in place by friction with some duct tape for good measure.

20161112_003 by Alan, on Flickr

20161112_003 by Alan, on FlickrThe slots in the gunwale are obviously oversized so I can slip it over the hull. At the bow and stern where it starts to curve towards the stems the gunwales want to tip in, kind of pigeon toed, and the oversized slots lets them do so. I added some clamps and counterweights to flatten them back out.

20161112_004 by Alan, on Flickr

20161112_004 by Alan, on FlickrAlan