Well she's been flipped and weighed. 32 pounds as she sits now so probably low/mid 50's by the time it's all said and done?

Got a start roughly scraping and sanding the inside but it appears I'm coming down with a cold and sore throat so sanding it's much fun at the moment. Think I'll wait until I either feel better or get really bored.

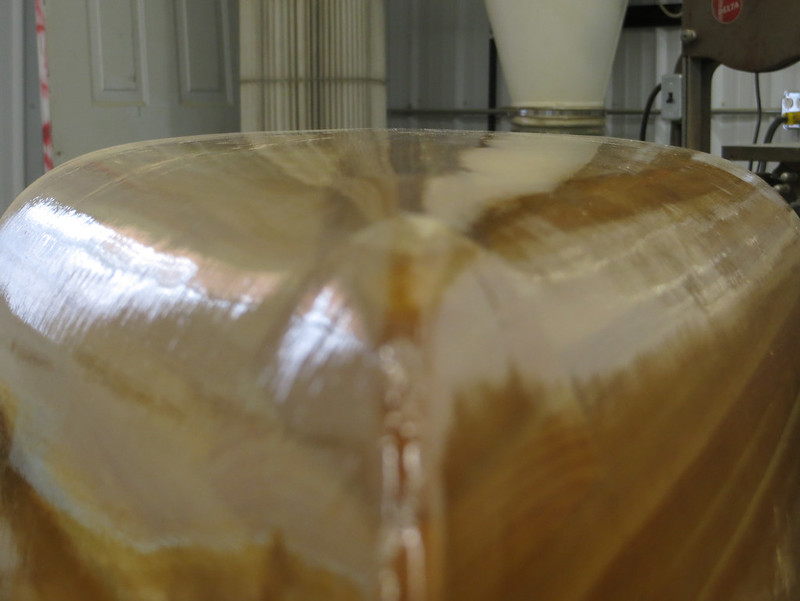

20141221_001 by Alan Gage, on Flickr

20141221_003 by Alan Gage, on Flickr

20141221_004 by Alan Gage, on Flickr

So far sanding the inside seems much easier on this than the skinny solos with extreme tumblehome, so that's nice for a change.

Alan

Got a start roughly scraping and sanding the inside but it appears I'm coming down with a cold and sore throat so sanding it's much fun at the moment. Think I'll wait until I either feel better or get really bored.

20141221_001 by Alan Gage, on Flickr

20141221_003 by Alan Gage, on Flickr

20141221_004 by Alan Gage, on Flickr

So far sanding the inside seems much easier on this than the skinny solos with extreme tumblehome, so that's nice for a change.

Alan