I took the raven on the Allagash 2c weeks ago from churchill dam to allagash village.

About a mile into the trip in chase rapids I second guessed my line and went left too late. The stern stuck and I pinned on a big rock mid river.

We were able to get it off the rock, started to bail water when I lost my balance, stopped the upstream gunwale, re-filled the canoe with water and it smashedinto a downstream rock.

We got it to river left, whiteout the canoe and decided it was safe to paddle the 4 miles to bissonette bridge.

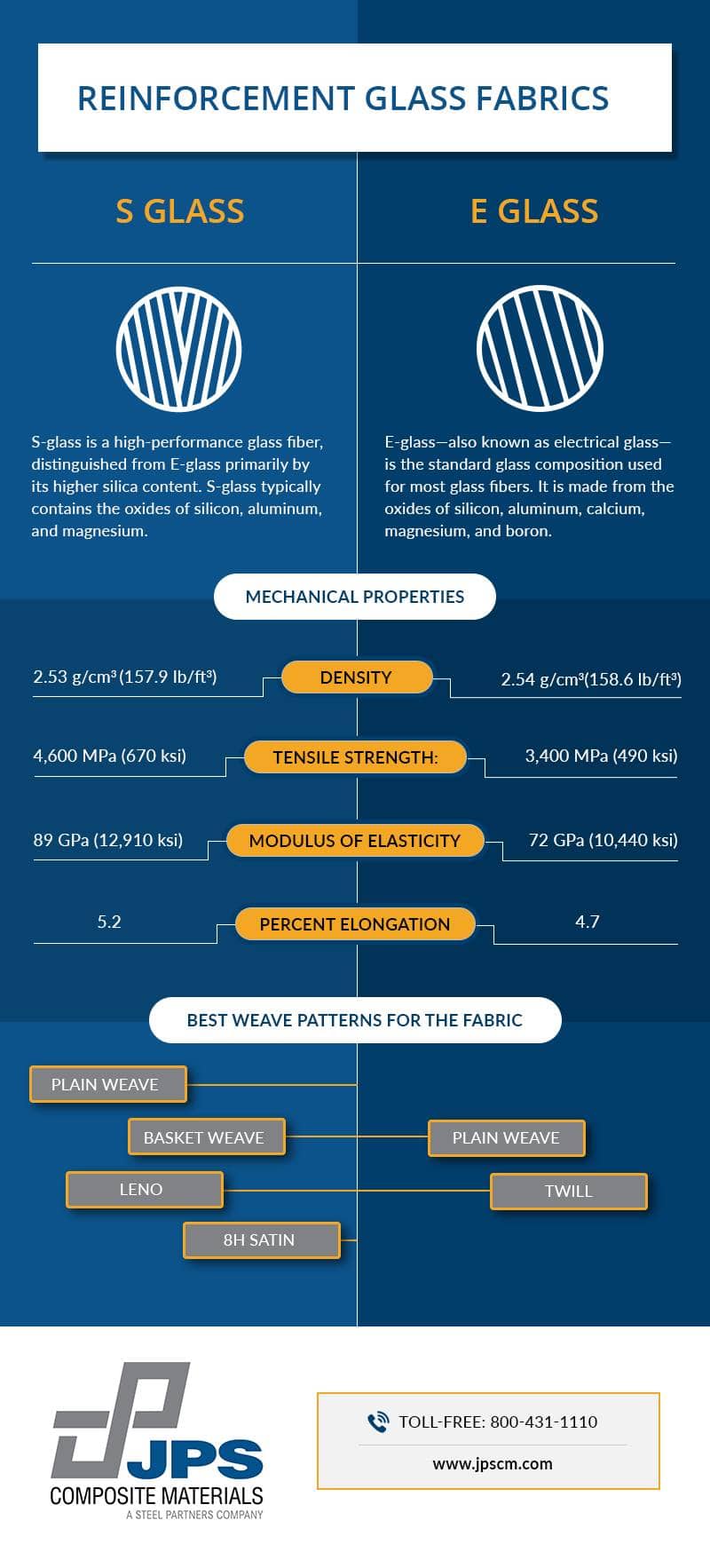

This the damage was most severe on the interior. One place where the 6 oz. E-glass split at the spot of biggest impact and several other places where the glass either broke or developed stress fractures along poor joints or weak wood grain.

My immediate thought is to repair with 4 oz. S- glass inside.

Thoughts?

About a mile into the trip in chase rapids I second guessed my line and went left too late. The stern stuck and I pinned on a big rock mid river.

We were able to get it off the rock, started to bail water when I lost my balance, stopped the upstream gunwale, re-filled the canoe with water and it smashedinto a downstream rock.

We got it to river left, whiteout the canoe and decided it was safe to paddle the 4 miles to bissonette bridge.

This the damage was most severe on the interior. One place where the 6 oz. E-glass split at the spot of biggest impact and several other places where the glass either broke or developed stress fractures along poor joints or weak wood grain.

My immediate thought is to repair with 4 oz. S- glass inside.

Thoughts?