Hello All

Yup, I'll admit it. I've been slacking....

So I cut the sheets I needed out of a couple of rough old full size sheet pans 10-11 days ago and they turned out to be .040" thick which was my original plan anyway. And it confirmed that the projected dimensions of 15" wide, 8-3/8" deep, 12" tall overall with 4" of vertical back panel and the shelf set at the bottom of the back panel would fit a 1/4 sized commercial sheet pan (half a household sheet pan) with four clear inches above the rack in the rear of the oven and ample air circulation around the pan.

Figuring out how to cut properly sized slots so that the .040" panels weren't flopping around led to ordering a $12 solid carbide 1/16" diameter router bit so there would be just a few hundredths of an inch clearance. Which router bit I managed to snap off almost immediately due to careless handling of the router.

Note to self: 1/16" solid carbide bits are brittle little things.

But freehand cuts with a .045" thin cut-off wheel in an angle grinder and a bit of dressing up with a hack saw blade did the trick for the slots although the cut off wheel raised a horrible burr around the underside of the slots.

And the old sheet pan metal was ugly enough that it gave me a rash so I made my first trip to the Greensboro branch of the Alro Steel Outlet. Boy, that should have been my first stop when this project started. They have "remnant" steel, stainless steel, aluminum, brass, copper, Delrin, acetyl and UHMW polyethylene with very reasonable prices.

Second quality .040" aluminum sheet with a few dings or scratches was $1.85 a pound or about $.50 a square foot. Remnant stainless steel in shapes was $3.80 a pound. I got a 4x4' sheet of .040" and a 2x4' .030 sheet (to try a small ultralight solo oven) and 10' of 3/16" stainless round rod (for shelf rods). Oh, and I got some UHMW poly sheet to make a few jigs. And a couple of 1/4" sheet 8x16" pieces in case the poly sheet didn't work out. So enough to make several big ovens (they take a bit under 4 square feet each), three or four small lightweight ovens and leftovers for tinkering with for around $38.

I had pretty much free-hand cut the locking tabs on the ugly sheet pan oven panels but since the dimensions were right I made a simple poly sheet jig to cut the locking tabs with a router and template guide and cut out the parts for an oven from the .040" sheet. The tab jig worked fine. As the replacement router bit hadn't arrived I cut the slots with the angle grinder. So the side panel got a fair bit of scratches from getting rid of the burrs from hell around the slots.

Note to self: save the darn grinder for cutting the stainless rod you big dummy. I should have waited for the replacement router bit as removing the burrs scratched the sheet pretty badly.

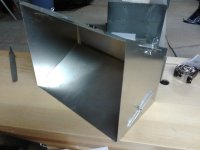

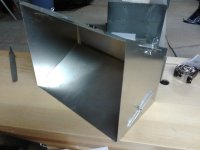

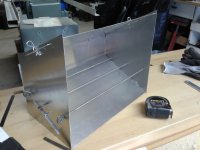

Here's the first oven made from the clean "remnant"sheet without the shelf rods installed yet. Note the scratches around the slots. You can even see them in the shadows on the far panel. The rash is back......

The only small hinges on hand were black so the back panel got a custom upgrade to the highly desirable custom black accent hinges. Yeah, that's it, no mistakes here, it's all custom accents.

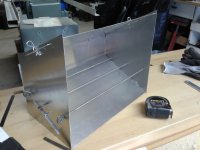

And with the stainless shelf rods.... The loop ends are so that the rods can be used as a light duty set of fire irons over a fire without rolling away and dumping the pot. Err, don't ask why I know that they need this.

And with the 9-1/2x13" quarter sheet pan.

And with a six cup muffin pan. I spaced the rods at 3" on center which proved to be sized for the muffing cups to sit perfectly in between the rods, almost like I planned it. But not only didn't I plan it but the bottoms would likely burn before the tops baked if they sat that low so I'll play with shelf rod spacing and see whether I can use the three rods or need to use four because Nancy (AKA Betty Crocker to the neighbors) will pout if she can't bake muffins in camp. And no, that's not her muffin pan it's a parts pan for when I disassemble stuff. It was someones nice tinned steel pan at one time though.

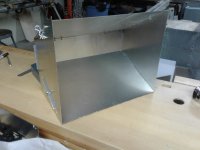

Lastly, knocked flat. I'll use a mini carabiner to capture the rods and pins. I may even rivet a cord for the 'biner to the lower rear of a side panel where it won't see much heat.

So.... Lessons learned to date:

The .040" aluminum is plenty stiff enough for this without being too heavy. The whole oven weighs 2 pounds 5 ounces (1000g) with the rods being 7 ounces (200g) of it.

Making the oven narrower or wider is always on option as it only needs setting the tablesaw fence to the desired width when cutting sheet down. The original plans called for a much wider oven as it was designed for large group expeditions. Similarly, an oven for an 8 or 9" pan is easy, too. I made the tab jig to index off the end of the panel so length is infinitely variable.

Hinging the rear panel likely adds 1-1/2 to 2 ounces (35-50g) of hinge and rivet weight. If I didn't have the door I'd be cutting two more tabs and two more slots to hold the back panel on. I'll use the oven some before passing judgement on the rear door. But I already know that the rear door will want a tab on the bottom panel to hold it snugly closed with a simple straight pin.

And as the back panel isn't fixed there is a premium on tight fitting slots to keep the whole thing from being floppy. The tab for the rear door will help stiffen it some.

If it needs more stiffening I'll mark where the rods pass through the side panel and use the .045" cutoff wheel to run a shallow groove around the rod to have it kind of hook over the side panel and help stiffen the whole thing.

The new router bit for the slots came this afternoon so I'll make a simple jig for cutting the slots. The rash is better already.

So why the fussing with details and jigs? Nancy and I met many moons ago when our oldest sons were Cub Scouts together. We have five sons and a daughter so I spent 14-15 years as a scout leader with 11 as a Scoutmaster. I only stepped back when the youngest son turned 18. Now, as grand kids reach scouting age the boys are coming back into scouting as adult leaders. Heck, after an 11-12 year break I'm back and active with scouting, too. And so I think that some reflector ovens in a couple of sizes are in the future gift rotation for sons and grand kids......

We're going boondocking near Mount Rogers in the Washington and Jefferson National Forest Saturday so I'll use the oven some this next week. After I'm back I'll paint one side of the panels black and test it to see if it us more efficient with a dark surface.

So enough rambling for now. I hope it was worth your time to read it all.

Best regards to all. We pray that all in the Canoetripping clan and their families stay healthy.

Lance