G

Guest

Guest

I had some ideas for refurbishing the Pathfinder, starting with turning it into a dedicated, center seat solo and ending with some custom outfitting as a potential fishing canoe.

Actually, with the Pathfinder in the shop, starting with some improvements to the existing kevlar felt skid plates.

The skid plates on the Pathfinder truly were hideous. While the actual kevlar felt is well attached, no doubt using a (now $300) Old Town kit with good urethane resin, the felt was not perimeter taped, so the resin outline is sloppy, in some places extending an inch beyond the edge of the fabric.

PB270009 by Mike McCrea, on Flickr

PB270009 by Mike McCrea, on Flickr

PB270010 by Mike McCrea, on Flickr

PB270010 by Mike McCrea, on Flickr

Additionally, the wide ends of the skid plate resin were long, uneven and in places thin of resin, lifting or fingernail lift-able, and needed to be removed before any prettification efforts commenced.

PB290004 by Mike McCrea, on Flickr

PB290004 by Mike McCrea, on Flickr

I was able to remove the already lifted or lift-able edges by cutting them nearer the fabric with a razor blade, but removing some of the large drips and gobs of urethane resin along the sides required a hammer, chisel, and razor blade, and I gave up on that effort after eliminating the worst of them (and, oopsie, chiseling small divots of vinyl off the RX)

PB290008 by Mike McCrea, on Flickr

PB290008 by Mike McCrea, on Flickr

No way in hell and I going to try to chisel, grind, scrape or sand that entire skid plate off. I have heard, perhaps apocryphally, of people doing so, including claims that “It just popped right off”, leading me to believe that it was not very well attached to begin with. What I have never seen are how-to photos or any honest account of how challenging it was, or what a mess it left behind to be filled and faired smooth (before Dynel application, one would hope).

I am not going that route with the Pathfinder; that ancient kevlar felt is still very well attached. But I can at least make them less fugly. The usual steps:

Tape an edge line. Further away from the felt than I would like because of the wobbly edged urethane resin, but c’est la vie.

PB290009 by Mike McCrea, on Flickr

PB290009 by Mike McCrea, on Flickr

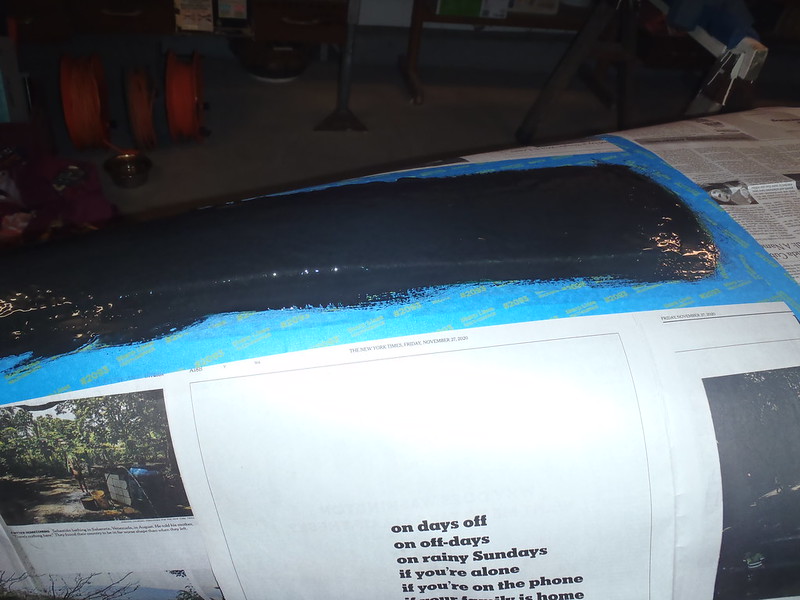

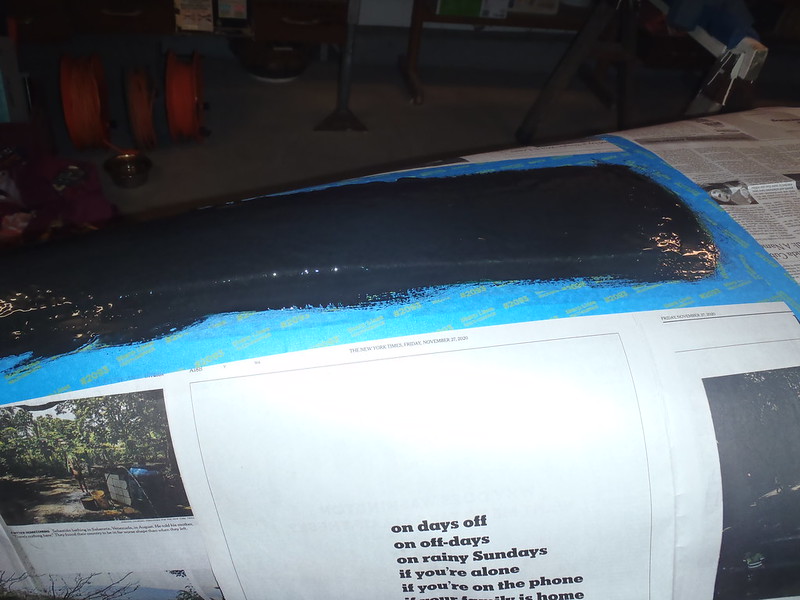

Paper mask to catch the drips, and tape again.

PB290013 by Mike McCrea, on Flickr

PB290013 by Mike McCrea, on Flickr

One note about taping over tape to secure the newspaper, which I do so that epoxy or paint drips don’t creep behind the paper mask; tape does not adhere as well to tape as it does to the hull, areas always lift a bit, and it pays to press it back down a final time immediately before brushing or rolling. And have some acetone ready when you pull the tape/mask, just in case.

The usual skid plate top coat mix, 50/50 West 105/206 and G/flex, graphite powder and black pigment, a thickened concoction which helped smooth out the worn-smoother-but still-pebbly-after-20-years kevlar felt surface.

One beneficial thing about that slurry mix, beyond making the skid plates slippery, at max 10% by volume (or less) the graphite powder nicely thickens the epoxy mix, and it better stays where put without dripping wastefully down onto the paper.

PB300017 by Mike McCrea, on Flickr

PB300017 by Mike McCrea, on Flickr

While painting that epoxy mix on I laid a thicker bead around the perimeter of the kevlar felt, to soften the kevlar felt transition edge and (hopefully) lessen any gurgle.

FWIW, volumetrically, one each pump of 105/206 resin/harder and an equal amount of G/flex. That was more than enough, but I had wisely set aside something brush on the excess. Less than 1lb of weight added, well worth it for better adhered, sharper lined, blacker, slipperier, more aesthetically pleasing skid plates.

I gave that four hours to begin to set up and pulled the tape and paper. The epoxy mix surface, as usual, looked pitch black, but a day later, after the epoxy cured, it looked off-color, greenish to my color blind eye, although my son told me it was actually more of a dark grey. I had not seen that action before; maybe I used too little graphite powder or black pigment in the epoxy mix.

PB300025 by Mike McCrea, on Flickr

PB300025 by Mike McCrea, on Flickr

With straight epoxy or even a mix of G/flex there is always a little epoxy bleed crept under the tape, but thickened a bit with Graphite powder the edge lines are fairly uncrept straight. I gave that epoxy mix a week to full cure, sanded the surface, retaped and top coated with black EZ-Poxy paint.

PC090003 by Mike McCrea, on Flickr

PC090003 by Mike McCrea, on Flickr

Much more attractive, and more slippery functional.

Note that the 100+ sap drips are gone. In order to remove the jokes-on-me bandaids I had stuck over the sap drips for Glenn’s amusement I had to spray the bandaids with 91% alcohol and scrape the adhesive residue off with a straight razor. In doing so I realized that the alcohol also softened the sap drips, and that I could remove them with the razor as well, although they required multiple mistings with a spray bottle of alcohol.

PB280011 by Mike McCrea, on Flickr

PB280011 by Mike McCrea, on Flickr

In a weekly share-ideas phone conversation with a boat tinkerer friend he suggested soaking a cotton ball with alcohol and letting it rest on a sap drip for a minute, move it to the next drip and scrape away at the alcohol saturated one. Some of the thicker sap drips required multiple cotton ball soakings, moving the cotton ball back and forth between sap drip A and B. Maybe more effort than it was really worth, but the hull bottom is now clean.

FWIW, I ran out of 91% alcohol and tried 70% alcohol. Still worked, but not as well. What the hell, I tried white vinegar; that did bupkis. I expect acetone of Goof-off would be even speedier, but I didn’t want to leave an acetone soaked cotton ball resting on the vinyl skin. Guess I need to buy a bottle of Everclear.

Whadda ya think Glenn, is the bottom now less fugly? Almost acceptable?

I can now turn the Pathfinder right side up and commence with some soloization and outfitting cogitation, again trying to use what I have available in the shop.

Actually, with the Pathfinder in the shop, starting with some improvements to the existing kevlar felt skid plates.

The skid plates on the Pathfinder truly were hideous. While the actual kevlar felt is well attached, no doubt using a (now $300) Old Town kit with good urethane resin, the felt was not perimeter taped, so the resin outline is sloppy, in some places extending an inch beyond the edge of the fabric.

PB270009 by Mike McCrea, on Flickr

PB270009 by Mike McCrea, on Flickr PB270010 by Mike McCrea, on Flickr

PB270010 by Mike McCrea, on FlickrAdditionally, the wide ends of the skid plate resin were long, uneven and in places thin of resin, lifting or fingernail lift-able, and needed to be removed before any prettification efforts commenced.

PB290004 by Mike McCrea, on Flickr

PB290004 by Mike McCrea, on FlickrI was able to remove the already lifted or lift-able edges by cutting them nearer the fabric with a razor blade, but removing some of the large drips and gobs of urethane resin along the sides required a hammer, chisel, and razor blade, and I gave up on that effort after eliminating the worst of them (and, oopsie, chiseling small divots of vinyl off the RX)

PB290008 by Mike McCrea, on Flickr

PB290008 by Mike McCrea, on FlickrNo way in hell and I going to try to chisel, grind, scrape or sand that entire skid plate off. I have heard, perhaps apocryphally, of people doing so, including claims that “It just popped right off”, leading me to believe that it was not very well attached to begin with. What I have never seen are how-to photos or any honest account of how challenging it was, or what a mess it left behind to be filled and faired smooth (before Dynel application, one would hope).

I am not going that route with the Pathfinder; that ancient kevlar felt is still very well attached. But I can at least make them less fugly. The usual steps:

Tape an edge line. Further away from the felt than I would like because of the wobbly edged urethane resin, but c’est la vie.

PB290009 by Mike McCrea, on Flickr

PB290009 by Mike McCrea, on FlickrPaper mask to catch the drips, and tape again.

PB290013 by Mike McCrea, on Flickr

PB290013 by Mike McCrea, on FlickrOne note about taping over tape to secure the newspaper, which I do so that epoxy or paint drips don’t creep behind the paper mask; tape does not adhere as well to tape as it does to the hull, areas always lift a bit, and it pays to press it back down a final time immediately before brushing or rolling. And have some acetone ready when you pull the tape/mask, just in case.

The usual skid plate top coat mix, 50/50 West 105/206 and G/flex, graphite powder and black pigment, a thickened concoction which helped smooth out the worn-smoother-but still-pebbly-after-20-years kevlar felt surface.

One beneficial thing about that slurry mix, beyond making the skid plates slippery, at max 10% by volume (or less) the graphite powder nicely thickens the epoxy mix, and it better stays where put without dripping wastefully down onto the paper.

PB300017 by Mike McCrea, on Flickr

PB300017 by Mike McCrea, on FlickrWhile painting that epoxy mix on I laid a thicker bead around the perimeter of the kevlar felt, to soften the kevlar felt transition edge and (hopefully) lessen any gurgle.

FWIW, volumetrically, one each pump of 105/206 resin/harder and an equal amount of G/flex. That was more than enough, but I had wisely set aside something brush on the excess. Less than 1lb of weight added, well worth it for better adhered, sharper lined, blacker, slipperier, more aesthetically pleasing skid plates.

I gave that four hours to begin to set up and pulled the tape and paper. The epoxy mix surface, as usual, looked pitch black, but a day later, after the epoxy cured, it looked off-color, greenish to my color blind eye, although my son told me it was actually more of a dark grey. I had not seen that action before; maybe I used too little graphite powder or black pigment in the epoxy mix.

PB300025 by Mike McCrea, on Flickr

PB300025 by Mike McCrea, on FlickrWith straight epoxy or even a mix of G/flex there is always a little epoxy bleed crept under the tape, but thickened a bit with Graphite powder the edge lines are fairly uncrept straight. I gave that epoxy mix a week to full cure, sanded the surface, retaped and top coated with black EZ-Poxy paint.

PC090003 by Mike McCrea, on Flickr

PC090003 by Mike McCrea, on FlickrMuch more attractive, and more slippery functional.

Note that the 100+ sap drips are gone. In order to remove the jokes-on-me bandaids I had stuck over the sap drips for Glenn’s amusement I had to spray the bandaids with 91% alcohol and scrape the adhesive residue off with a straight razor. In doing so I realized that the alcohol also softened the sap drips, and that I could remove them with the razor as well, although they required multiple mistings with a spray bottle of alcohol.

PB280011 by Mike McCrea, on Flickr

PB280011 by Mike McCrea, on FlickrIn a weekly share-ideas phone conversation with a boat tinkerer friend he suggested soaking a cotton ball with alcohol and letting it rest on a sap drip for a minute, move it to the next drip and scrape away at the alcohol saturated one. Some of the thicker sap drips required multiple cotton ball soakings, moving the cotton ball back and forth between sap drip A and B. Maybe more effort than it was really worth, but the hull bottom is now clean.

FWIW, I ran out of 91% alcohol and tried 70% alcohol. Still worked, but not as well. What the hell, I tried white vinegar; that did bupkis. I expect acetone of Goof-off would be even speedier, but I didn’t want to leave an acetone soaked cotton ball resting on the vinyl skin. Guess I need to buy a bottle of Everclear.

Whadda ya think Glenn, is the bottom now less fugly? Almost acceptable?

I can now turn the Pathfinder right side up and commence with some soloization and outfitting cogitation, again trying to use what I have available in the shop.