G

Guest

Guest

A recent thread got me thinking about using cordlocs to tension painter line bungees, and leaving some extra bungee length left dangling for adjustability when using longer/thicker painter lines, or re-tensioning over existing painters as the bungee stretched out.

http://www.canoetripping.net/forums/...flotation-tank

280 character Tweet version:

Using quality cordlocs presents multiple advantages as adjustable painter keepers. And maybe used on thwart bungees as well. I need more quality cordlocs.

The idea of passing two bungee ends run through a single cordloc, centered on the underneath bungee diagonal of my usual deck plate Z-pattern, might work with the right cordloc.

(Yes, 280 characters exactly. Doesn't quite explain the concept and application)

The aperture on even my largest cordlocs is too small to fit for 2X of my preferred bungee. ITW Nexus may have something in a cordloc (or other cord grasping product?) that will accommodate adjusting two bungee ends at once, maybe the Dual Hole cordloc.

http://na.itwnexus.com/products/cate.../cord-products

I could use a single cordloc on the end of that over/under/over bungee Z-pattern. But if I give up the (rarely used) diagonal under run of bungee I can eliminate some proven bungee wear and tear areas using the cordlocs I have on hand.

Crap, I was down to a total of four good quality cordlocs. And a bunch of crappy ones that I wouldn’t trust to hold a stuff bag draw string; little surprise that all the good cordlocs all got used up first. I see a cordloc order in my future.

P4150002 by Mike McCrea, on Flickr

P4150002 by Mike McCrea, on Flickr

The smaller cordlocs are still high strength/quality (ITW Nexus) and will accommodate 3/16” bungee. The big rectangular cordlocs (also once an ITW Nexus product) have a huge opening, wide enough for the ¼” bungee I prefer.

Bungee I got, but waste not want not. I cut the existing bungees off a boat in the shop from the bow and stern at the stopper knot; that gave me two 14” pieces of bungee, conveniently pre-knotted at one end.

P4150004 by Mike McCrea, on Flickr

P4150004 by Mike McCrea, on Flickr

Run up from underneath, against that stopper knot, back down the rabbit hole on the other side and through a cordloc, that 14” length seemed excessive when fully extended, although less so after I stopper knotted the bitter end so the bungee couldn’t be pulled through the cordloc.

P4150009 by Mike McCrea, on Flickr

P4150009 by Mike McCrea, on Flickr

First cordloc adjustment test, using the existing shorter, thinner painter lines, held under adjustable tension bungee on that canoe. I need to replace those lines (and the gone fugly ugly Tygon tubing painter handle) while I’m working on that canoe, and now don’t need to worry about sizing bungee taut to length and stopped knotted, which was always a persnickety tensioning process that too often ended with “Eh, that’s kinda tight, but it’ll stretch out”.

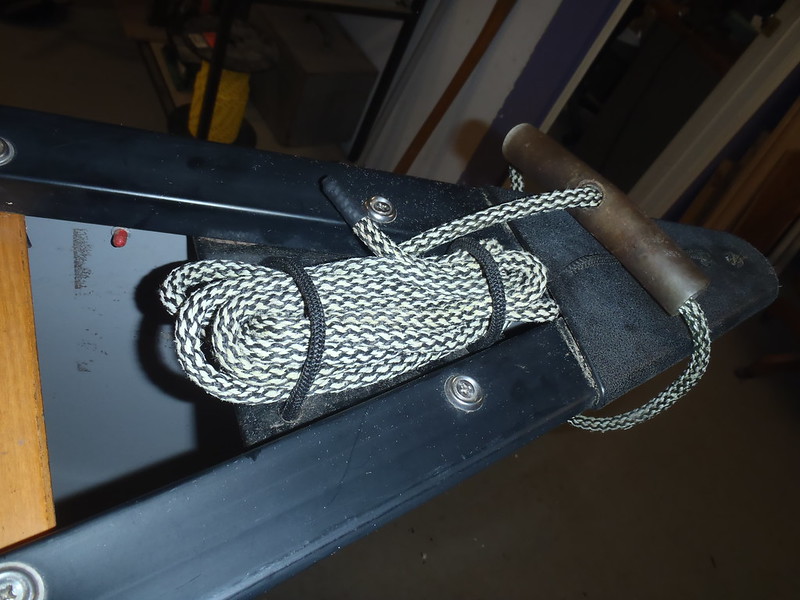

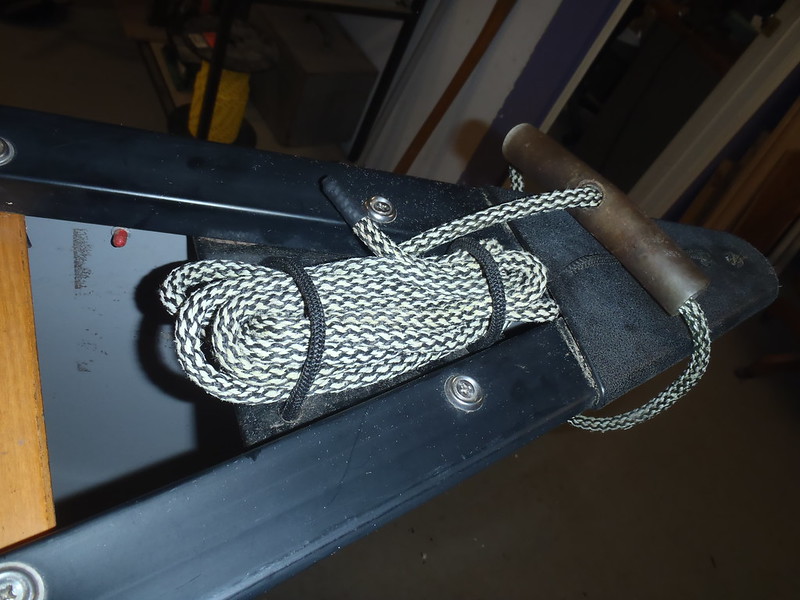

P4150006 by Mike McCrea, on Flickr

P4150006 by Mike McCrea, on Flickr

Second test, longer, thicker painter lines installed under those adjustable bungees and tensioned firm, without bungee killing overstretch. The cordlocs will eliminate stretching out the bungee when switching to different painters.

P4150011 by Mike McCrea, on Flickr

P4150011 by Mike McCrea, on Flickr

Even with the longer/thicker painter I had 5” of excess bungee dangle under the plate. A bit less after stopper knotting the ends, but still plenty of dangle for an easy grab and adjust.

I duplicated that on the stern, using 3/16” bungee and the smaller cordlocs. I cut that bungee at 12” lengths; turns out that is as short as I’d want; having at least 4” of dangle is helpful to blind grab, pull and tension. Oddly, those smaller cordlocs have an even firmer grip on the bungee. I wish I had another couple dozen of those, whatever the hell ITW they were.

P4160016 by Mike McCrea, on Flickr

P4160016 by Mike McCrea, on Flickr

I already like that cordloc adjustability for painter keeper bungees, enough give up the (rarely used) under-deck diagonal and re-do a bunch of our canoes. If I don’t overstretch the bungee between different painters it should last longer, and the cordloc adjustable bungee tension holds perfectly over whatever painter line selection I might choose to use.

To verify that I gave them some test pulls, including “oh-crap” grab-and-snatch, hurriedly extracting the painter line from between the bungee without looking, and by pulling directly up on the bungee loops; the bungee stretches a long ways before the cordlocs slip.

I like the cordloc concept for a future reason as well. I plan to add some recessed, under-inwale deck extensions made of multi-layer carbon fiber. With the exposed carbon sides trimmed with car door edging so I don’t slit my wrist. But I expect the carbon fiber holes would play hell slicing up a single Z-run of bungee pulled taut on an angle.

With two separate pieces the bungee is pulling more vertically, lodged against a stopper knot or cordloc, not grinding across even a dull or chamfered edge. I might try to sleeve the carbon fiber holes with a small plastic flange, I think I have some is the miscellaneous box

That bungee wear is not so much a problem on (thicker) wood with chamfered holes, although a single cordloc on one end of an over/under/over on a thwart bungee would have similar tensioning adjustability advantages.

P5010759 by Mike McCrea, on Flickr

P5010759 by Mike McCrea, on Flickr

The hole edge wear eventually becomes apparent even with bungee keepers through vinyl deck plates. All of our canoes with big vinyl deck plates have a / \ of bungee, with the customary diagonal Z leg underneath.

P4060719 by Mike McCrea, on Flickr

P4060719 by Mike McCrea, on Flickr

Those bungees, pulled through vinyl decks and not sharper-edged carbon fiber, always wear thin where the bungee passes through the hole. Enough that I recently replaced the worn-thin painter keeper bungees on a couple canoes. That’s a waste of bungee, and a maintenance issue I’d like to avoid as long as possible.

I may try the ITW/Nexus Dual Hole cordloc on a single Z-run of bungee, just to satisfy my curiosity and see if/how it works, but I think eliminating the Z angled tension will significantly help lessen wear and tear on the bungee cord as it passes through the hole.

I know that avoiding overstretch, and having the bungee adjustable to accommodate different painter line lengths and strengths, will help immediately. Those two things are the bungee killers.

dang, I’m gonna need a bunch more sturdy, large aperture cordlocs. See what you went and did Mnoutdoorfunguy!

http://www.canoetripping.net/forums/...flotation-tank

280 character Tweet version:

Using quality cordlocs presents multiple advantages as adjustable painter keepers. And maybe used on thwart bungees as well. I need more quality cordlocs.

The idea of passing two bungee ends run through a single cordloc, centered on the underneath bungee diagonal of my usual deck plate Z-pattern, might work with the right cordloc.

(Yes, 280 characters exactly. Doesn't quite explain the concept and application)

The aperture on even my largest cordlocs is too small to fit for 2X of my preferred bungee. ITW Nexus may have something in a cordloc (or other cord grasping product?) that will accommodate adjusting two bungee ends at once, maybe the Dual Hole cordloc.

http://na.itwnexus.com/products/cate.../cord-products

I could use a single cordloc on the end of that over/under/over bungee Z-pattern. But if I give up the (rarely used) diagonal under run of bungee I can eliminate some proven bungee wear and tear areas using the cordlocs I have on hand.

Crap, I was down to a total of four good quality cordlocs. And a bunch of crappy ones that I wouldn’t trust to hold a stuff bag draw string; little surprise that all the good cordlocs all got used up first. I see a cordloc order in my future.

The smaller cordlocs are still high strength/quality (ITW Nexus) and will accommodate 3/16” bungee. The big rectangular cordlocs (also once an ITW Nexus product) have a huge opening, wide enough for the ¼” bungee I prefer.

Bungee I got, but waste not want not. I cut the existing bungees off a boat in the shop from the bow and stern at the stopper knot; that gave me two 14” pieces of bungee, conveniently pre-knotted at one end.

Run up from underneath, against that stopper knot, back down the rabbit hole on the other side and through a cordloc, that 14” length seemed excessive when fully extended, although less so after I stopper knotted the bitter end so the bungee couldn’t be pulled through the cordloc.

First cordloc adjustment test, using the existing shorter, thinner painter lines, held under adjustable tension bungee on that canoe. I need to replace those lines (and the gone fugly ugly Tygon tubing painter handle) while I’m working on that canoe, and now don’t need to worry about sizing bungee taut to length and stopped knotted, which was always a persnickety tensioning process that too often ended with “Eh, that’s kinda tight, but it’ll stretch out”.

Second test, longer, thicker painter lines installed under those adjustable bungees and tensioned firm, without bungee killing overstretch. The cordlocs will eliminate stretching out the bungee when switching to different painters.

Even with the longer/thicker painter I had 5” of excess bungee dangle under the plate. A bit less after stopper knotting the ends, but still plenty of dangle for an easy grab and adjust.

I duplicated that on the stern, using 3/16” bungee and the smaller cordlocs. I cut that bungee at 12” lengths; turns out that is as short as I’d want; having at least 4” of dangle is helpful to blind grab, pull and tension. Oddly, those smaller cordlocs have an even firmer grip on the bungee. I wish I had another couple dozen of those, whatever the hell ITW they were.

I already like that cordloc adjustability for painter keeper bungees, enough give up the (rarely used) under-deck diagonal and re-do a bunch of our canoes. If I don’t overstretch the bungee between different painters it should last longer, and the cordloc adjustable bungee tension holds perfectly over whatever painter line selection I might choose to use.

To verify that I gave them some test pulls, including “oh-crap” grab-and-snatch, hurriedly extracting the painter line from between the bungee without looking, and by pulling directly up on the bungee loops; the bungee stretches a long ways before the cordlocs slip.

I like the cordloc concept for a future reason as well. I plan to add some recessed, under-inwale deck extensions made of multi-layer carbon fiber. With the exposed carbon sides trimmed with car door edging so I don’t slit my wrist. But I expect the carbon fiber holes would play hell slicing up a single Z-run of bungee pulled taut on an angle.

With two separate pieces the bungee is pulling more vertically, lodged against a stopper knot or cordloc, not grinding across even a dull or chamfered edge. I might try to sleeve the carbon fiber holes with a small plastic flange, I think I have some is the miscellaneous box

That bungee wear is not so much a problem on (thicker) wood with chamfered holes, although a single cordloc on one end of an over/under/over on a thwart bungee would have similar tensioning adjustability advantages.

The hole edge wear eventually becomes apparent even with bungee keepers through vinyl deck plates. All of our canoes with big vinyl deck plates have a / \ of bungee, with the customary diagonal Z leg underneath.

Those bungees, pulled through vinyl decks and not sharper-edged carbon fiber, always wear thin where the bungee passes through the hole. Enough that I recently replaced the worn-thin painter keeper bungees on a couple canoes. That’s a waste of bungee, and a maintenance issue I’d like to avoid as long as possible.

I may try the ITW/Nexus Dual Hole cordloc on a single Z-run of bungee, just to satisfy my curiosity and see if/how it works, but I think eliminating the Z angled tension will significantly help lessen wear and tear on the bungee cord as it passes through the hole.

I know that avoiding overstretch, and having the bungee adjustable to accommodate different painter line lengths and strengths, will help immediately. Those two things are the bungee killers.

dang, I’m gonna need a bunch more sturdy, large aperture cordlocs. See what you went and did Mnoutdoorfunguy!

Last edited: