- Joined

- Jul 6, 2021

- Messages

- 643

- Reaction score

- 564

Moving Sexy Thang around without any carry handles has been a PITA. While I have preferred model strap-style handles those require climbing far into the decks to hold a nut while someone else turns the bolt. They are 2-person carry comfortable, but also a 2-person PITA to install, and the handles end up at an awkward leg banging hull width, far from the stems.

P9230013 by Mike McCrea, on Flickr

P9230013 by Mike McCrea, on Flickr

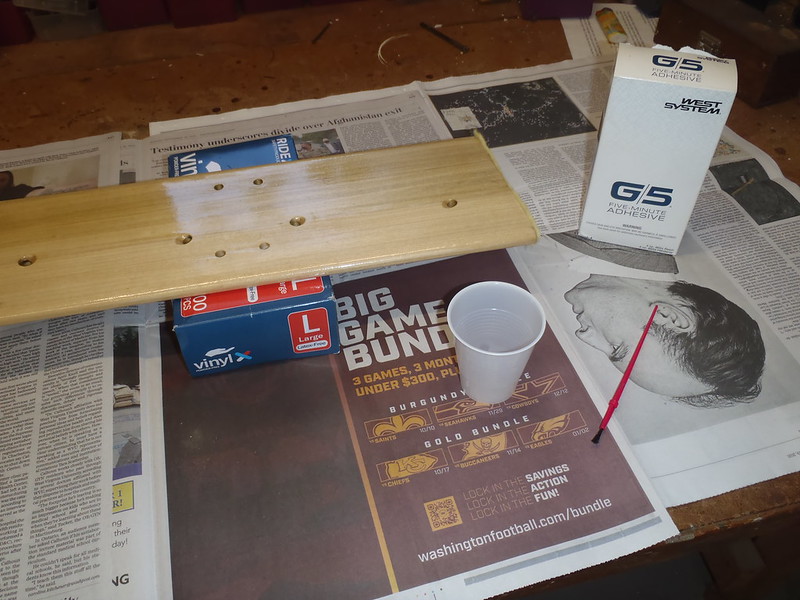

Plus I don’t actually have any of those left in stock, and I’m trying to do this outfitting with what I have on hand. Note: I recently heard the “I already had it on hand” explanation from a fellow boat tinkerer. Yeah, you and me both brother, but it isn’t like the magical Parts and Pieces Fairies left it in the shop for me one night; at some point I bought that stuff. We just tell ourselves that so rebuilds seem less expensive.

The toggle grips I thought I had, which still have not reappeared after repeated searches, were these.

https://topkayaker.com/index.php?main_page=product_info&cPath=2_134&products_id=700

Now $15 apiece? $30 for a pair of plastic carry handles? I think not. Probably just as well I can’t find where I stashed those; I had installed them on a decked boat conversion, found the hard plastic shape of the toggle uncomfortable in hand and slippery to grasp, and quickly replaced them.

I needed a kiss solution for DIY toggles handles, something I could use through the old rope holes at the far ends of either stem, and have come to like bicycle handlebar grips as grab handles on canoe bow loops, especially the grippy no-slip texture.

P9220002 by Mike McCrea, on Flickr

P9220002 by Mike McCrea, on Flickr

Cut the end flanges off the bike grips, cut a length of PVC pipe to sleeve inside as a stiffener; the PVC pipe was a perfect snug fit, tight enough that it needed some lubrication, drill a center hole through the handle grip and pipe for the rope.

P9230004 by Mike McCrea, on Flickr

P9230004 by Mike McCrea, on Flickr

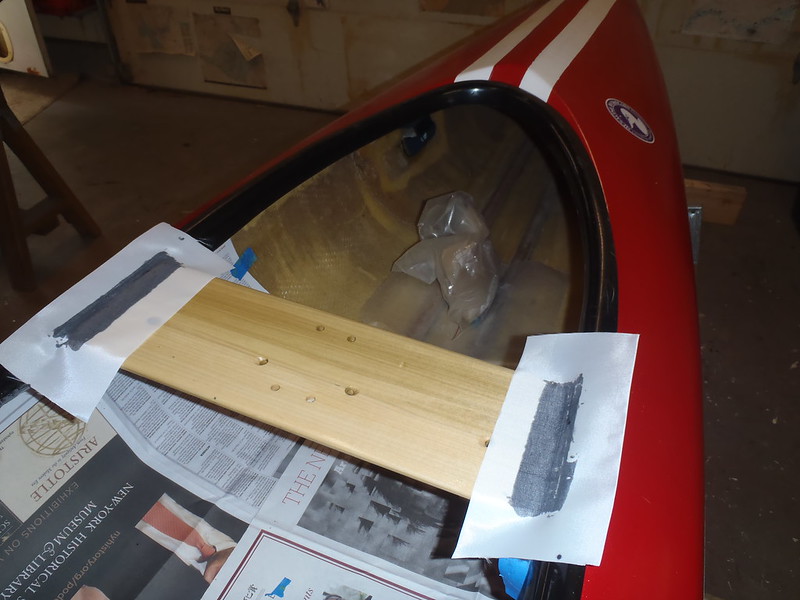

I pulled the interior end of the rope through the deck holes at the stems, all the way into the cockpit and ran that bitter end through a neoprene cushioned washer to help spread the load. Sexy Thang already had a glob of ‘70’s quintessential thickened resin there at the rope handle tip inside the deck.

P9230005 by Mike McCrea, on Flickr

P9230005 by Mike McCrea, on Flickr

Tied a stopper knot, filled the washer base with E-6000 adhesive, pulled it tight to the inside stem and clamped it off while the E-6000 set up.

P9230008 by Mike McCrea, on Flickr

P9230008 by Mike McCrea, on Flickr

Once the adhesive on the neoprene washer set up I ran the end of the rope into the toggle handle, pulled a few inches out, tied another stopper knot and slid the knot inside the PVC pipe. It took some pushing and lubrication to force the stopper knots inside the handles, so everything should be held tightly in place.

Presto, DIY black, cushioned, no-slip toggle handles. Two bike grips (which I guess the Parts and Pieces Fairies left), two short lengths of PVC pipe, less than a foot of high quality rope on each, counting the stopper knots.

P9230011 by Mike McCrea, on Flickr

P9230011 by Mike McCrea, on Flickr

I made the stern carry toggle rope a bit longer, in hopes that once the rudder is attached it will still be usable. If I need to refashion the stern toggle for rudder clearance I can afford another short length of rope, but for now at least Sexy Thang is easier to two-person carry. Should be fine bow toggle in hand on a portage cart too.

I may have to consider doing an end-pour of floatation foam in the stems, even with the minicel pedestal and knee bumpers & heel pads to come there is not a lot of flotation in Sexy Thang. The interior stem ends have nothing but some globed resin pour at the tips, and now a strand of E-6000 dripping off the washers.

P9230010 by Mike McCrea, on Flickr

P9230010 by Mike McCrea, on Flickr

I will glue in D-rings to tie off DIYed decked canoe sized tapered dry bags or float bags for day paddling/sailing.

https://www.canoetripping.net/threads/more-tapered-dry-bags.98705/

P9230013 by Mike McCrea, on Flickr

P9230013 by Mike McCrea, on FlickrPlus I don’t actually have any of those left in stock, and I’m trying to do this outfitting with what I have on hand. Note: I recently heard the “I already had it on hand” explanation from a fellow boat tinkerer. Yeah, you and me both brother, but it isn’t like the magical Parts and Pieces Fairies left it in the shop for me one night; at some point I bought that stuff. We just tell ourselves that so rebuilds seem less expensive.

The toggle grips I thought I had, which still have not reappeared after repeated searches, were these.

https://topkayaker.com/index.php?main_page=product_info&cPath=2_134&products_id=700

Now $15 apiece? $30 for a pair of plastic carry handles? I think not. Probably just as well I can’t find where I stashed those; I had installed them on a decked boat conversion, found the hard plastic shape of the toggle uncomfortable in hand and slippery to grasp, and quickly replaced them.

I needed a kiss solution for DIY toggles handles, something I could use through the old rope holes at the far ends of either stem, and have come to like bicycle handlebar grips as grab handles on canoe bow loops, especially the grippy no-slip texture.

P9220002 by Mike McCrea, on Flickr

P9220002 by Mike McCrea, on FlickrCut the end flanges off the bike grips, cut a length of PVC pipe to sleeve inside as a stiffener; the PVC pipe was a perfect snug fit, tight enough that it needed some lubrication, drill a center hole through the handle grip and pipe for the rope.

P9230004 by Mike McCrea, on Flickr

P9230004 by Mike McCrea, on FlickrI pulled the interior end of the rope through the deck holes at the stems, all the way into the cockpit and ran that bitter end through a neoprene cushioned washer to help spread the load. Sexy Thang already had a glob of ‘70’s quintessential thickened resin there at the rope handle tip inside the deck.

P9230005 by Mike McCrea, on Flickr

P9230005 by Mike McCrea, on FlickrTied a stopper knot, filled the washer base with E-6000 adhesive, pulled it tight to the inside stem and clamped it off while the E-6000 set up.

P9230008 by Mike McCrea, on Flickr

P9230008 by Mike McCrea, on FlickrOnce the adhesive on the neoprene washer set up I ran the end of the rope into the toggle handle, pulled a few inches out, tied another stopper knot and slid the knot inside the PVC pipe. It took some pushing and lubrication to force the stopper knots inside the handles, so everything should be held tightly in place.

Presto, DIY black, cushioned, no-slip toggle handles. Two bike grips (which I guess the Parts and Pieces Fairies left), two short lengths of PVC pipe, less than a foot of high quality rope on each, counting the stopper knots.

P9230011 by Mike McCrea, on Flickr

P9230011 by Mike McCrea, on FlickrI made the stern carry toggle rope a bit longer, in hopes that once the rudder is attached it will still be usable. If I need to refashion the stern toggle for rudder clearance I can afford another short length of rope, but for now at least Sexy Thang is easier to two-person carry. Should be fine bow toggle in hand on a portage cart too.

I may have to consider doing an end-pour of floatation foam in the stems, even with the minicel pedestal and knee bumpers & heel pads to come there is not a lot of flotation in Sexy Thang. The interior stem ends have nothing but some globed resin pour at the tips, and now a strand of E-6000 dripping off the washers.

P9230010 by Mike McCrea, on Flickr

P9230010 by Mike McCrea, on FlickrI will glue in D-rings to tie off DIYed decked canoe sized tapered dry bags or float bags for day paddling/sailing.

https://www.canoetripping.net/threads/more-tapered-dry-bags.98705/