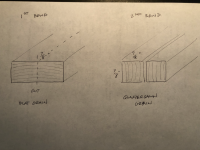

It's too cold in my 'shop', the unheated barn, to accomplish any big jobs so I spent a few minutes experimenting with a sled on which to shape the underside of the future decks for this canoe. The idea is to relieve the underside of the decks so they appear "lighter"; not in the sense of weight but rather give a more delicate appearance to the underside of the decks. I did not want to remove material from the entire underside of the deck, just the back end of each. The upper surfaces of the decks will be crowned using plane and spokeshave once the triangular shape is cut out.

I used a couple of scrap 1x's to serve as runners under the deck blank, and clamped a fence to my table saw at 45 degrees to the blade. I affixed the deck blank to the runners with the stem end of the blank elevated by another scrap 1x so the undercut would not extend to the end of the blank. That would weaken the sides of the triangular deck once cut out of the blank. It's necessary to screw through the inwales into the sides of the finished deck, so the deck can't be weak near the tip.

My experiment was done on a piece of 4/4 pine, but the actual decks will be cut from 5/4 tiger maple so the undercut can probably be a bit deeper on the actual deck material.

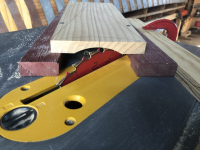

45 degree fence; runners in red:

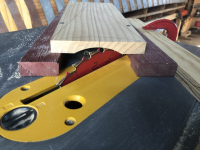

Deck blank in cutting position:

Side view showing elevated front position:

Underside stock removal result:

I think I can make a gentler arc if I move the fence closer to 90 degrees to the fence. Unfortunately this may increase the danger inherent in the cutting process. For that I should mount handles to the runners to keep a better grip on the work and keep my hands away from the blade. I do know that each pass should not remove much material, thereby reducing the chance of the blade throwing the workpiece. It ain't worth losing a finger to make a dainty deck!