For the prior weight attempt I simply held the canoe on my haunches but in thinking over this method I can imagine how that arrangement could've registered a lighter weight given I was somewhat off balance. Having the weight directly above the scale is more sensible. 68 lbs...Must be glass.

Before I had a hanging scale I used the bathroom scale and found that how I held the boat while standing on the scale made a difference. Even holding it balanced under the yoke could produce a half pound difference between weighings, holding it at waist level could result in a couple pounds variance between repeated weighings. I guess bathroom scale aren’t designed for something with a 16 foot long belly or head.

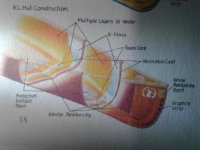

The more I read about glass canoes the more I understand their benefits as in rigidity, sharper entry points (efficiency), and lighter than Royalex which I wouldn't have guessed. I would imagine a well-built glass canoe such as this will not oil-can and am wondering if typical kevlar ultralights do? Probably depends on ribs, etc. Ultimately I would love to take this boat on a trip and trying to justify the additional portage weight assuming paddling efficiency gains.

Composite canoes usually have sharper stems, and a Vermont made glass MRC should not oil can as Royalex sometimes does. The vee bottom of MRC boats helps in that regard as well, as opposed to a flat bottom or shallow arch canoe. Depending on the bottom shape some UL canoes do oil can a bit and other materials were infamous for oil canning (poly boats, early Twin-tex hull).

Vermont made MRC glass boats have a deserved reputation for being tough and well constructed.

On our most recent trip we did 120km/75mi in 6.5 days of moving. Two atypical layover days not counted. In those 6.5 days we logged 30 total portages for a total of 10,350M which is just shy of 6.5 miles with none of it being flat or easy.

I would not want to carry a 68 lb canoe further than my roof racks to the water’s edge. Your knees and back may vary. For now.

My lake trips might involve a single short portage, or more often none at all. As such I am sometimes paddling on lakes large enough to move camp a time or two and day paddle/explore on layover days.

Which means large, often windy, lakes. Large windy lakes with rocky shorelines. That does not produce easy conditions for launching and landing, loading and unloading. When I look at the damage done to our boats a lot of the scrapes, gouges and dings (and one cracked hull on a UL canoe) come from struggling on rocky shorelines in the wind.

I would much rather have a stoutly built glass canoe than a ultra-light composite in those launching and loading challenges. To say nothing of subjecting a new technologies and materials $3000 hull to that abuse. Egads!

WIth that all said I am going to work towards lightening our overall load & try to get a handle on paddling efficiency gains with this boat vs the We-no-nah Boundary Waters Ultralight we took last as the trip is fresh in my mind. Maybe you have insight on this?

BWAHAHA! I am the last person to speak about lightening the load. If you want to add 50 lbs of creature comforts I’m your guy.

Paddling efficiency means some seat time in different conditions (flat, windy, choppy, etc) with different strokes, and some practiced coordination between bow and stern. Straight blade, bent shaft, what length? Still lots to discover about that canoe.

Am also going to put out the feelers for more MR boats of this vintage in hopes of scoring another as MN is a good place for this and I have an untapped, affluent source in mind.

The right number of canoes is just one more. If you turn up a lighter weight boat more suitable for portaging I’d still keep the Sunrunner. It is a Vermont MRC boat, so probably very well constructed, and a bit of a rarity/curiosity.

I am trying to avoid terming that 25 year old near pristine canoe a, gulp, “

beater”, but

Recently picked this beauty up for a song.

For rocky shore trips or yanking over beaver dams I’d take the stout glass Sunrunner over a UL canoe any day. Especially any composite with a foam core.

for showing me that kevlar sundance. Anyone want to buy a ceramics kiln, motorcycle, or some nice vintage hifi audio equipment???

for showing me that kevlar sundance. Anyone want to buy a ceramics kiln, motorcycle, or some nice vintage hifi audio equipment???