The black hull was the following year, a 6 week nearly 600 mile trip

I remember. That's the kind of wilderness river trip that's out of the norm for most canoes, so, as I said, it does make sense to beef up a stripper/composite canoe when your life depends on it. If I were young and strong, I'd probably only take a Royalex canoe on an igneous river, even if that seems ignominious.

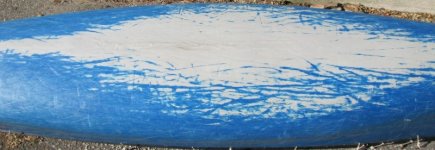

You did a nicely dense pattern with the scratches, even up past the waterline. The diagonal and horizontal ones must have been exciting.

These were not highly rockered boats so if I found a rock, which happened regularly, the stems usually took the first hit.

That's an interesting point. All my dedicated whitewater canoes are highly rockered, so that's probably part of the reason I don't have much stem damage on them. And I've never run any of my composite lake canoes or kayaks on rocky whitewater, and always wet foot them. Come to think of it, I've never taken a composite canoe on a long trip that had both lakes and whitewater rivers. I bought my SRT for that purpose, but . . . .

I've also found that since I started building canoes I'm more likely to be hard on them.

I've wondered whether paddlers who like to build and repair boats have that sort of psychology lurking within. I know I have the opposite psychology. The only "glassing" I've ever done in my life was that one set of skid plates 40 years ago. Otherwise, I've paid people to repair my canoes. And since I'm cheap, I've probably always tended to be very careful with my composite boats. Nick Schade, kayak builder extraordinaire, once told me I was babying my carbon hull seakayak when I refused to run it aground in the Bay of Fundy and opted to do "fall out landings" instead.

By the way, for Mike McCrea and Steve'n Idaho, that full carbon infused hull has clear gel coat with gold flecks in it, per my custom specifications. The builder had never made one like it. I bought a Swedish carbon double paddle (Vitudden or VKV) that has the same thing, which I'll try to get in a picture below. Well, you can see the flecks, but the flash has washed out their gold color. The hull of my Surge seakayak is the same, while the deck is Kevlar with yellow gel coat and the deck-hull seam is red.

Last edited: