G

Guest

Guest

Happy Birthday Glenn. I have marked October 31 on my anal retentive calendar as “Glenn M B-day”. Unbeknownst to me I mailed you a birthday present yesterday, an envelope with a couple pieces of low profile 4575 for your inspection.

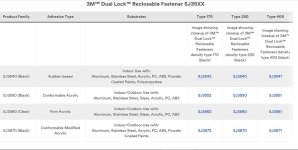

That is a very generous offer and I’d like to test the 250-to-250, especially in terms of how difficult it is to seat the mushroom heads for spray cover use. No strain gauge; I never foresaw that I would be doing this many tests with various canoe outfitting attachment points.

One good thing about forgetting to set the clocks back; I woke up at my usual “4:30am”, made coffee and started playing in the shop, only to discover that it was actually 3:30am when I looked at the computer. Oh well, I have plenty of dirt, mud, sand, shop spider webs and insect carcasses.

I stirred up a witch’s brew slurry of that goo and smeared it on all of the test pieces of low profile Dual Lock. I’ll give it a day or two to thoroughly dry/cake on and see how easily it cleans out. I’ll be interested in how it compares to similarly goo’ed up Velcro and will do the same with test pieces of hook & loop. Might as well do the goo clean up test with the 250 test pieces, thinking that larger, more widely spaced “mushrooms” might be easier to clean.

My last “test” with the 4575 will be to see how difficult it is to detach the acrylic adhesive backing, even if that means digging under it with a screwdriver or razor blade.

Or maybe not “last”; one thing with these silly shop experiments, I often think of some additional procedure or abuse to try.

That is a very generous offer and I’d like to test the 250-to-250, especially in terms of how difficult it is to seat the mushroom heads for spray cover use. No strain gauge; I never foresaw that I would be doing this many tests with various canoe outfitting attachment points.

One good thing about forgetting to set the clocks back; I woke up at my usual “4:30am”, made coffee and started playing in the shop, only to discover that it was actually 3:30am when I looked at the computer. Oh well, I have plenty of dirt, mud, sand, shop spider webs and insect carcasses.

I stirred up a witch’s brew slurry of that goo and smeared it on all of the test pieces of low profile Dual Lock. I’ll give it a day or two to thoroughly dry/cake on and see how easily it cleans out. I’ll be interested in how it compares to similarly goo’ed up Velcro and will do the same with test pieces of hook & loop. Might as well do the goo clean up test with the 250 test pieces, thinking that larger, more widely spaced “mushrooms” might be easier to clean.

My last “test” with the 4575 will be to see how difficult it is to detach the acrylic adhesive backing, even if that means digging under it with a screwdriver or razor blade.

Or maybe not “last”; one thing with these silly shop experiments, I often think of some additional procedure or abuse to try.