Stripperguy, I recall that you attach a movable solo bucket seat to composite floor rails using 3M Dual Lock. I'm thinking of using it for a movable wooden solo seat on wooden rails -- strips of it on the "slider" rails and a patch of it on each of the four corners of the seat rails. This would make the seat movable and removable (though not slidable) and would avoid kludgy slider clamps or brackets. Just plop it on the slider rail where you want it and move it, or remove it, when necessary. This solution would also be a way to kick out of a foot entrapment under a wooden bench seat.

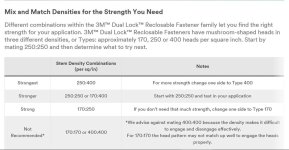

Which of the three densities of the product did you use?

How many square inches of contact surface? Too much contact area might be hard to remove or rip the glue side off the rails.

Do you remove the seat to portage?

Do you remove the seat to cartop?

Has the adhesion of the mushroom side or glue side of the tape failed or begun to fail?

Thanks for any info and pictures you can provide.

Which of the three densities of the product did you use?

How many square inches of contact surface? Too much contact area might be hard to remove or rip the glue side off the rails.

Do you remove the seat to portage?

Do you remove the seat to cartop?

Has the adhesion of the mushroom side or glue side of the tape failed or begun to fail?

Thanks for any info and pictures you can provide.