-

Happy Patent for First Computer Mouse (1970)! 🖥️🖱️🐁

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

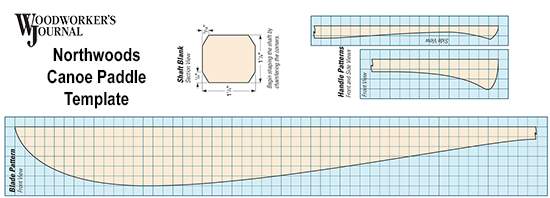

Free beavertail paddle plans

- Thread starter Murat V

- Start date

- Joined

- Mar 20, 2013

- Messages

- 3,356

- Reaction score

- 479

Always good to have other ideas, different ways of doing things, and designs!

Thank you Murat

Thank you Murat

Thanks for sharing. Nice little tutorial and template. I'll keep an eye out for that right piece of wood and try to make one. Mark

- Joined

- Nov 19, 2013

- Messages

- 1,400

- Reaction score

- 414

Murat - Thanks for this great info. I've already printed it out.

Take care and until next time...be well.

snapper

Take care and until next time...be well.

snapper

Well, I found that 2x8x8' clear cedar board at the lumber yard last week and decided to use these plans to make my first canoe paddle. After destroying my lightweight paddle last summer, this might become my spare for long portage type trips. How did I destroy my paddle you ask? Horse flies. I have a high tolerance for mosquitoes and other insects, but deer and horseflies drive me crazy. Horseflies are usually easy to deal with though, and fun. I hold still until they go into a holding pattern around my head. Holding the paddle in just the right position and I swing for the fences. In this case my swing brought the paddle across the gunwale and it splintered into pieces. At first I was horrified because I thought I had busted up the gunwale. I was able to do a serviceable field repair, but the paddle now permanently hangs in the shop, a testament to keeping a cool head.

Here's where I'm at. I think I've got the length right, but I'm afraid the blade may be a bit on the small side. We'll have to see once it's all done.

Mark

Here's where I'm at. I think I've got the length right, but I'm afraid the blade may be a bit on the small side. We'll have to see once it's all done.

Mark

- Joined

- Mar 20, 2013

- Messages

- 3,356

- Reaction score

- 479

dang nice piece of wood!! Two things you might already know but should consider, is the size of your shaft on a cedar paddle, go a bit bigger than suggested, I usually go 1 3/8 X 1 3/16ish for a good oval shaft! Also tip protection. there is a lot of different ways to achieve that. I do a spline in the end of my paddles.

Looking great so far! The cathedral pattern on the blade will look awesome!!

Looking great so far! The cathedral pattern on the blade will look awesome!!

I thought about making the shaft heavier, but in the end just went with the standard 1 1/4 x 1 1/8 for some reason. I plan to be cautious and not do too much sanding once I get the edges knocked off. I haven't decided on a tip, but I think I will put either some glass or thickened epoxy. I finally finished my cedar greenland kayak paddle this fall and it showed obvious damage after just 2 days on the water.

- Joined

- Mar 20, 2013

- Messages

- 3,356

- Reaction score

- 479

I thought about making the shaft heavier, but in the end just went with the standard 1 1/4 x 1 1/8 for some reason. I plan to be cautious and not do too much sanding once I get the edges knocked off. I haven't decided on a tip, but I think I will put either some glass or thickened epoxy. I finally finished my cedar greenland kayak paddle this fall and it showed obvious damage after just 2 days on the water.

I had good success with G-Flex as a "bumper".

I got the paddle blade, shaft and grip roughed out and put on an epoxy tip last night. I used the paddle to trace a couple of cardboard cutouts of the paddle shape and clamped them to the paddle. This gives a tip that is a little thicker on the tip of the paddle and tapers down each side. I wetted the blade edge with epoxy then filled the inside with cedar thickened epoxy with a little microfiber added in for good measure.

This part of the process all started out with a little bit of drama. I grabbed my fast hardener and thought I had grabbed the gallon of resin, but instead grabbed the gallon of slow hardener. After mixing the appropriate amounts and waiting and waiting I started to think, the fast hardener should have firmed up by now. I looked over at the jug and realized my mistake.

I scraped it all off, wiped it down with some acetone, roughed it up with some sandpaper and started over. Hopefully the residual hardener that soaked into the wood won't cause a problem. Oh well, my first paddle. If the tip comes off I'll just sand it down and do it again. I've got plenty of resin and it didn't take that long to do anyway.

Wow this paddle is light. I'll take the advice from Canotrouge and keep the blade a little thicker than recommended.

This part of the process all started out with a little bit of drama. I grabbed my fast hardener and thought I had grabbed the gallon of resin, but instead grabbed the gallon of slow hardener. After mixing the appropriate amounts and waiting and waiting I started to think, the fast hardener should have firmed up by now. I looked over at the jug and realized my mistake.

I scraped it all off, wiped it down with some acetone, roughed it up with some sandpaper and started over. Hopefully the residual hardener that soaked into the wood won't cause a problem. Oh well, my first paddle. If the tip comes off I'll just sand it down and do it again. I've got plenty of resin and it didn't take that long to do anyway.

Wow this paddle is light. I'll take the advice from Canotrouge and keep the blade a little thicker than recommended.

- Joined

- Mar 20, 2013

- Messages

- 3,356

- Reaction score

- 479

Looking good!!

Dogbrain ! You really got me going now !

Almost looks like you could glue the cutoffs together, and make another paddle !

Bummer with the mix up . I always just pour my resin, and just use pumps on my hardener. Keeps me from mixing them up, especially if the jugs look similar !

Need to trace that pattern out on my ash blank !

Thanks !

Jim

Almost looks like you could glue the cutoffs together, and make another paddle !

Bummer with the mix up . I always just pour my resin, and just use pumps on my hardener. Keeps me from mixing them up, especially if the jugs look similar !

Need to trace that pattern out on my ash blank !

Thanks !

Jim

Good idea Jim, maybe I'll laminate some other wood I have laying around here between the two cutoffs since it's a little thin in the upper part of the shaft area. I can see making another paddle in the near future. It's relatively fast and quite satisfying. Like building a strip canoe, my next paddle will take me less than half the time.

Mark

Mark

- Joined

- Mar 20, 2013

- Messages

- 3,356

- Reaction score

- 479

Tung oil is good, I would certainly thin the first coat to make it penetrate as much as possible... I really like the finish that I don't remember who did on his paddle, some kind of rub in wipe off epoxy finish... I think it would be great for a soft wood paddle!!

Very nice grain pattern! Several years ago I found a nice black walnut board with a flame grain pattern in it... IIRC the board only cost $10-$15 at the sawmill.

The only cedar paddle I've made seemed kind of fragile after carving was done so I sheathed it all in fiberglass. The potential problem with that was the blade needed to be sheathed on both sides at once since epoxy curing on one side only would warp it. I recorded the weights before and after glassing and the fiberglass didn't add that much to the total weight.

My guess is varnish would be more durable on cedar than oil.... cedar canoes are finished with varnish.

PS... your cedar paddle has much tighter grain than mine, so it may be harder wood and more durable. I once found a 4x4 with extremely tight grain, about 180 rings counted total, old growth forest being cut somewhere.

The only cedar paddle I've made seemed kind of fragile after carving was done so I sheathed it all in fiberglass. The potential problem with that was the blade needed to be sheathed on both sides at once since epoxy curing on one side only would warp it. I recorded the weights before and after glassing and the fiberglass didn't add that much to the total weight.

My guess is varnish would be more durable on cedar than oil.... cedar canoes are finished with varnish.

PS... your cedar paddle has much tighter grain than mine, so it may be harder wood and more durable. I once found a 4x4 with extremely tight grain, about 180 rings counted total, old growth forest being cut somewhere.

Last edited:

is there a measurement to determine the weight balance of a paddle so its not too heavy from ether blade or grip?

I like mine pretty evenly balanced with the blade being a little heavier. As far as a measurement goes I think it's trial and error, I usually keep taking wood off the blade and check the balance as I go.

I have had good results with boiled linseed oil, the key is to get it soaked in good. I recently read this; apply oil once a day for a week, once a week for a month, and once a month for a year.

I have done both varnish and oil and my next one will be oil. I think it protects better and is easier to apply and you could varnish over an already oiled paddle.

I'm a fan of a good quality spar varnish. First coat thinned 50/50 with mineral spirits, then two or three more as desired. If it can hold up to a salt water enviroment it's plenty of protection.

Dave

Dave

Similar threads

- Replies

- 3

- Views

- 465

- Replies

- 23

- Views

- 528

- Replies

- 8

- Views

- 1K